- Home

-

-

-

Stiles Enhancement Technologies

-

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

-

-

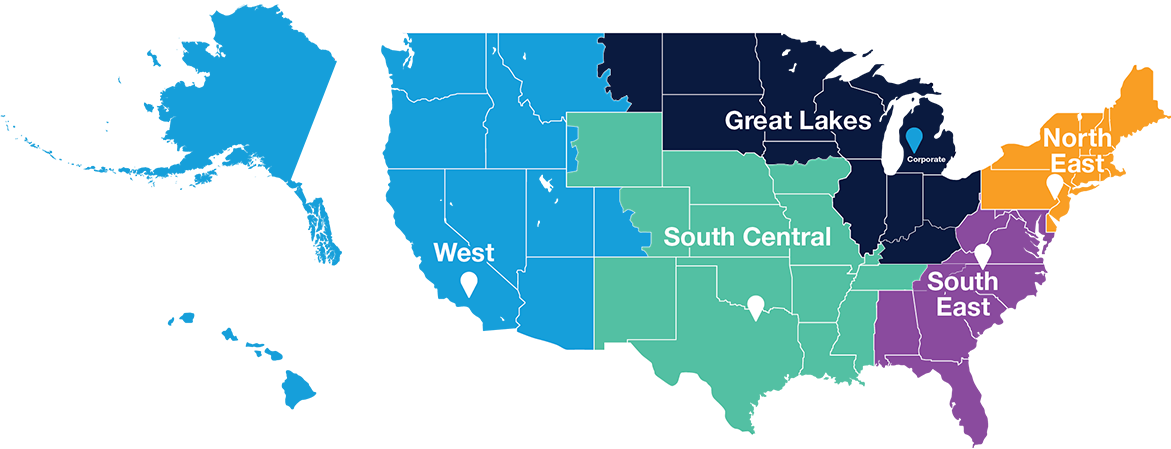

- Stiles Machinery hosts a national network of five regional service centers and nationwide force of over 200 Field Service Representatives put the industry’s best service where it belongs – close to you.

- Routine & Preventative Maintenance

- Technical Support & Diagnostics

- Field Service

- Request an Equipment Manual

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615

Service & Repairs: 616-698-7500

24/7 Parts: 1-800-727-8780

sale@inlandmachineokc.com

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

-

With a customized Stiles University course, we can provide expert training for your team, on-location. Whether it's programming, operation or maintenance, we want to help you train your personnel to meet your production goals efficiently and effectively.

-

Experience the trusted workforce development training and machinery knowledge you rely on from Stiles University, now at your convenience. With technology changing every day and new methods being developed constantly, Stiles University Online has the latest information and training content available at your fingertips.

-

Your solution for workforce development.

616-698-7500

-

-

-

Do you want to produce more efficiently? Processes and flows are key. We optimize these together with you, re-organize them and make sure that you reduce your lead time and save costs. This enables you to implement customized manufacturing and achieve your business goals.

-

Industrialized construction is evolving. Automation, robotics and advanced technology are raising the level of productivity, efficiency and precision for builders in North America.

-

Stiles Machinery is at the forefront of providing technology and machining for producing high quality mass timber. Automated solutions for your mass timber production can increase your manufacturing quality and productivity.

-

Project management services from Stiles make it easy to streamline your entire project— from concept and consultation to integration and implementation.

-

- Online Store

- News

- Careers

- REQUEST INFO

- Home

-

-

-

Stiles Enhancement Technologies

-

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

-

-

- Stiles Machinery hosts a national network of five regional service centers and nationwide force of over 200 Field Service Representatives put the industry’s best service where it belongs – close to you.

- Routine & Preventative Maintenance

- Technical Support & Diagnostics

- Field Service

- Request an Equipment Manual

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615

Service & Repairs: 616-698-7500

24/7 Parts: 1-800-727-8780

sale@inlandmachineokc.com

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

-

With a customized Stiles University course, we can provide expert training for your team, on-location. Whether it's programming, operation or maintenance, we want to help you train your personnel to meet your production goals efficiently and effectively.

-

Experience the trusted workforce development training and machinery knowledge you rely on from Stiles University, now at your convenience. With technology changing every day and new methods being developed constantly, Stiles University Online has the latest information and training content available at your fingertips.

-

Your solution for workforce development.

616-698-7500

-

-

-

Do you want to produce more efficiently? Processes and flows are key. We optimize these together with you, re-organize them and make sure that you reduce your lead time and save costs. This enables you to implement customized manufacturing and achieve your business goals.

-

Industrialized construction is evolving. Automation, robotics and advanced technology are raising the level of productivity, efficiency and precision for builders in North America.

-

Stiles Machinery is at the forefront of providing technology and machining for producing high quality mass timber. Automated solutions for your mass timber production can increase your manufacturing quality and productivity.

-

Project management services from Stiles make it easy to streamline your entire project— from concept and consultation to integration and implementation.

-

- Online Store

- News

- Careers

- REQUEST INFO

- Home

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

- TECHNICAL SUPPORT

- FIELD SERVICE

- ROUTINE & PREVENTATIVE MAINTENANCE

- REQUEST AN EQUIPMENT MANUAL

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615 Service & Repairs: 616-698-7500 24/7 Parts: 1-800-727-8780

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

- IN-PERSON TRAINING

- CUSTOMIZED COURSES & TRAINING

- STILES UNIVERSITY ONLINE

-

Your solution for workforce development.

- Online Store

- News

- Careers

- FINANCING

- Blog

- REQUEST INFO

- Home

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

- TECHNICAL SUPPORT

- FIELD SERVICE

- ROUTINE & PREVENTATIVE MAINTENANCE

- REQUEST AN EQUIPMENT MANUAL

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615 Service & Repairs: 616-698-7500 24/7 Parts: 1-800-727-8780

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

- IN-PERSON TRAINING

- CUSTOMIZED COURSES & TRAINING

- STILES UNIVERSITY ONLINE

-

Your solution for workforce development.

- Online Store

- News

- Careers

- FINANCING

- Blog

- REQUEST INFO

Top Wood CNC Machine Benefits for Your Business and Creative Projects

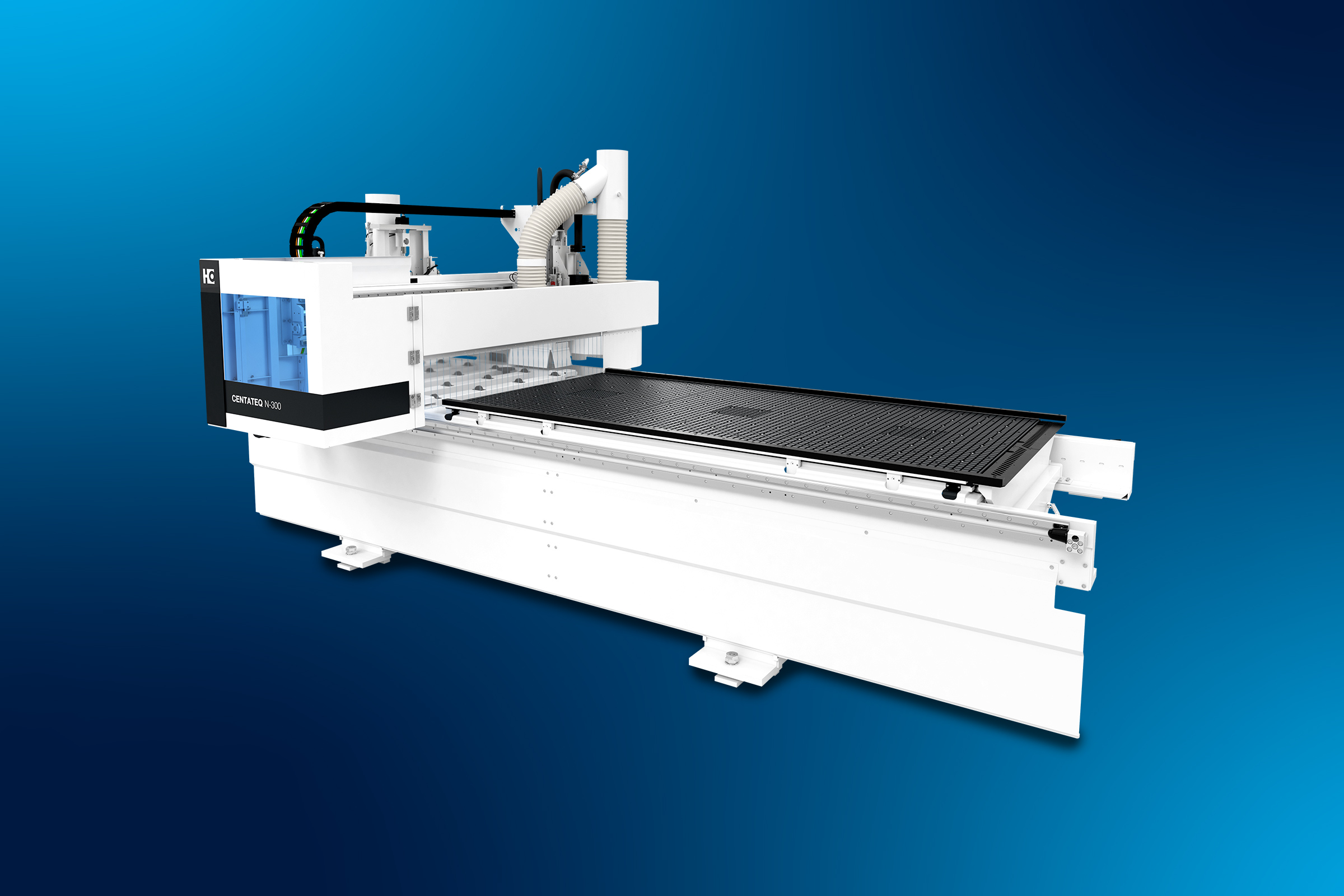

In the realm of woodworking and creative projects, the advent of the wood CNC machine has revolutionized the way artisans and businesses approach design and production. According to John Smith, a renowned expert in woodworking technology, "The wood CNC machine is not just a tool; it's a gateway to limitless creativity and precision." This powerful machinery allows users to translate intricate designs into tangible products with unprecedented accuracy, enabling both large-scale manufacturers and individual woodworkers to enhance their capabilities.

The benefits of incorporating a wood CNC machine into business practices extend beyond mere efficiency. With capabilities like customizable automation and intricate detailing, these machines empower businesses to streamline their production processes while minimizing waste. As a result, artisans are not only able to produce high-quality products faster but also explore more complex and creative designs that were once considered impractical. Embracing this technology can significantly impact the growth and success of creative projects, making it an essential investment for those looking to thrive in today’s competitive landscape.

Key Advantages of Using Wood CNC Machines in Business Operations

Wood CNC machines have revolutionized the way businesses approach woodworking and creative projects. One of the key advantages of using these machines is their precision and consistency. Unlike traditional woodworking methods that rely heavily on manual labor, CNC systems operate through computer programming, ensuring that each cut is exact and replicable. This level of precision significantly reduces material waste and enhances product quality, making it an ideal choice for businesses aiming to uphold high standards in craftsmanship.

Another important benefit is the efficiency these machines bring to production processes. Wood CNC machines can run continuously, increasing output while freeing up skilled labor for other tasks. This shift not only accelerates project timelines but also allows businesses to take on more work without compromising quality. Furthermore, the versatility of wood CNC machines enables users to tackle a wide range of designs and projects, from custom furniture to intricate decorative pieces, catering to varying customer demands effectively. By integrating these advanced tools into their operations, businesses can keep pace with market trends and enhance their creative offerings.

Enhanced Precision and Accuracy in Crafting Creative Projects

The advent of Wood CNC machines has revolutionized the landscape of creative projects, offering enhanced precision and accuracy that traditional methods struggle to achieve. These machines utilize advanced computer technology to guide cutting tools with pinpoint precision, allowing craftsmen to create intricate designs that were once labor-intensive or nearly impossible to replicate by hand. This capability means that even the most delicate features can be captured effortlessly, making the final product not only aesthetically pleasing but also consistent in quality.

Moreover, the versatility of CNC machines allows for a wide range of artistic expressions. Whether creating custom furniture, intricate sculptures, or personalized gifts, the precision offered by CNC technology ensures that each project can be tailored to the exact specifications of the designer. This level of accuracy is particularly beneficial in industries where details matter, such as architectural modeling or bespoke woodwork. Implementing CNC technology not only enhances the quality of the final creations but also streamlines the production process, ultimately providing businesses with the ability to scale their creative projects without sacrificing craftsmanship.

Increased Efficiency and Productivity in Woodworking Processes

The woodworking industry has seen a remarkable transformation with the advent of CNC (Computer Numerical Control) machines. These advanced machines have revolutionized the production process, enabling higher efficiency and productivity. By automating various tasks, businesses can significantly reduce the time spent on manual operations. This allows for faster turnaround times, ultimately leading to increased customer satisfaction and the ability to take on more projects.

Additionally, the precision offered by CNC machines contributes to a more streamlined workflow. With the capability to easily replicate designs and cut materials with incredible accuracy, the risk of errors is minimized. This not only enhances the quality of the final product but also decreases material waste, effectively lowering production costs. As a result, businesses can focus their resources on innovation and creativity, exploring new designs and improving their overall service offerings. The integration of wood CNC machines into woodworking processes marks a pivotal step towards maintaining a competitive edge in a rapidly evolving market.

Versatility of Wood CNC Machines for Various Applications

Wood CNC machines have emerged as essential tools for businesses and creative projects, largely due to their remarkable versatility in various applications. According to a recent industry report by MarketsandMarkets, the global CNC market is projected to reach $117 billion by 2025, driven by increasing automation and customization in manufacturing processes. Wood CNC machines facilitate this by allowing for intricate designs and precise cuts in materials ranging from plywood to hardwood, making them ideal for furniture design, cabinetry, and intricate art projects.

In addition to standard cutting and engraving functions, wood CNC machines are capable of executing various tasks, including drilling, inlay work, and adaptive manufacturing. This multi-functionality can greatly reduce production time and labor costs, as a single machine can handle multiple operations that would traditionally require different tools. Moreover, the ability to create precision components is critical in industries such as architecture and construction, where exact specifications are paramount. A study published in the Journal of Manufacturing Science and Engineering indicated that the use of CNC technology can improve productivity by up to 50%, underscoring the impact these machines have in enhancing operational efficiency.

Furthermore, the adaptability of wood CNC machines allows businesses to cater to diverse customer needs. For instance, they can easily switch between producing custom signages to crafting personalized home décor items. This flexibility not only meets varying market demands but also encourages innovation within the sector. As businesses continue to explore sustainable practices, wood CNC machines also contribute to waste reduction by optimizing material usage, aligning with the growing emphasis on eco-friendly manufacturing.

Top Wood CNC Machine Benefits for Your Business and Creative Projects

| Benefit | Description | Application Examples |

|---|---|---|

| Precision Cutting | CNC machines provide high precision in cutting wood, ensuring that parts fit together perfectly. | Furniture manufacturing, custom cabinetry. |

| Versatility | Can handle a variety of wood types and designs for different projects. | Signs, art pieces, model making. |

| Increased Productivity | CNC machines automate repetitive tasks, enhancing workflow. | Mass production of wooden goods, large-scale projects. |

| Cost Efficiency | Reduces material waste and labor costs, increasing profitability. | Furniture, woodworking crafts. |

| Customization | Easily create custom designs tailored to specific client requirements. | Personalized gifts, bespoke furniture. |

Cost-Effectiveness and Long-Term Savings for Companies

When integrating a wood CNC machine into your business operations, one of the most compelling advantages is the cost-effectiveness it brings.

According to a report from the International Wood Products Association, companies utilizing CNC technology have reported a reduction of up to 30% in production costs due to increased efficiency and precision. This technology minimizes material wastage, allowing businesses to maximize their raw material utilization, which is particularly critical in the wood industry where costs can be substantial.

Moreover, the long-term savings associated with wood CNC machines are significant. A study published by the Manufacturing Institute highlighted that companies investing in CNC technology can expect a return on investment (ROI) within the first two years of operation. The automated processes not only speed up production times but also reduce labor costs, as fewer operators are required to handle complex tasks. As skilled labor becomes increasingly scarce and expensive, adopting a CNC machine not only mitigates these costs but also enhances operational consistency, ultimately leading to higher profitability over time.

Related Posts

-

Unlocking Precision: How Wood CNC Machines are Revolutionizing the Furniture Industry

-

Unlocking Creativity: How CNC Wood Cutting Machines Transform Custom Furniture Design

-

Top 10 Wood Carving Machines for Professional and Hobby Use

-

How to Choose the Best CNC Router Kit for Your Woodworking Projects

-

Exploring the Future of Manufacturing: How CNC Machines are Revolutionizing Production Techniques

-

Unlocking the Potential of Wood CNC Machines for Your Next Creative Project