- Home

-

-

-

Stiles Enhancement Technologies

-

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

-

-

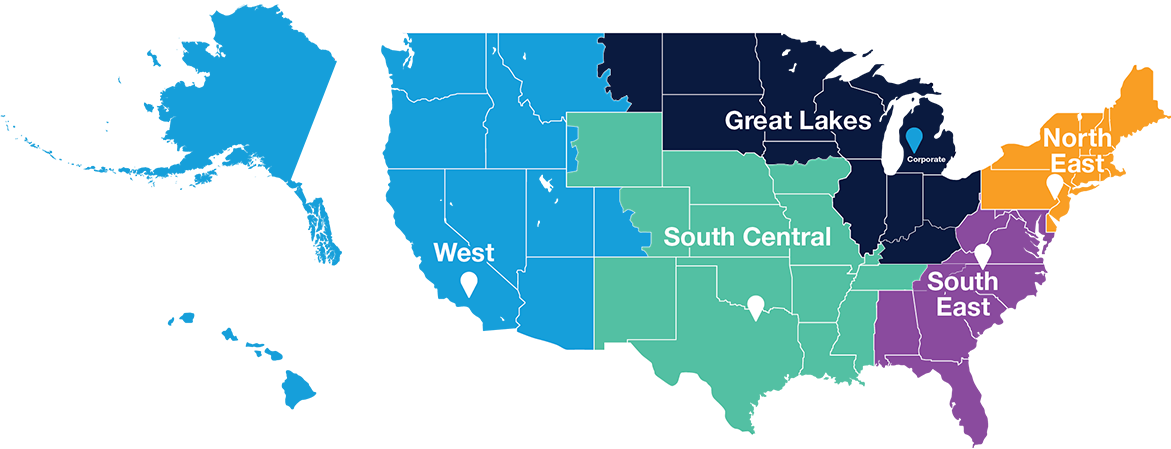

- Stiles Machinery hosts a national network of five regional service centers and nationwide force of over 200 Field Service Representatives put the industry’s best service where it belongs – close to you.

- Routine & Preventative Maintenance

- Technical Support & Diagnostics

- Field Service

- Request an Equipment Manual

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615

Service & Repairs: 616-698-7500

24/7 Parts: 1-800-727-8780

sale@inlandmachineokc.com

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

-

With a customized Stiles University course, we can provide expert training for your team, on-location. Whether it's programming, operation or maintenance, we want to help you train your personnel to meet your production goals efficiently and effectively.

-

Experience the trusted workforce development training and machinery knowledge you rely on from Stiles University, now at your convenience. With technology changing every day and new methods being developed constantly, Stiles University Online has the latest information and training content available at your fingertips.

-

Your solution for workforce development.

616-698-7500

-

-

-

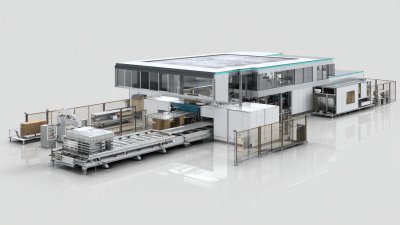

Do you want to produce more efficiently? Processes and flows are key. We optimize these together with you, re-organize them and make sure that you reduce your lead time and save costs. This enables you to implement customized manufacturing and achieve your business goals.

-

Industrialized construction is evolving. Automation, robotics and advanced technology are raising the level of productivity, efficiency and precision for builders in North America.

-

Stiles Machinery is at the forefront of providing technology and machining for producing high quality mass timber. Automated solutions for your mass timber production can increase your manufacturing quality and productivity.

-

Project management services from Stiles make it easy to streamline your entire project— from concept and consultation to integration and implementation.

-

- Online Store

- News

- Careers

- REQUEST INFO

- Home

-

-

-

Stiles Enhancement Technologies

-

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

-

-

- Stiles Machinery hosts a national network of five regional service centers and nationwide force of over 200 Field Service Representatives put the industry’s best service where it belongs – close to you.

- Routine & Preventative Maintenance

- Technical Support & Diagnostics

- Field Service

- Request an Equipment Manual

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615

Service & Repairs: 616-698-7500

24/7 Parts: 1-800-727-8780

sale@inlandmachineokc.com

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

-

With a customized Stiles University course, we can provide expert training for your team, on-location. Whether it's programming, operation or maintenance, we want to help you train your personnel to meet your production goals efficiently and effectively.

-

Experience the trusted workforce development training and machinery knowledge you rely on from Stiles University, now at your convenience. With technology changing every day and new methods being developed constantly, Stiles University Online has the latest information and training content available at your fingertips.

-

Your solution for workforce development.

616-698-7500

-

-

-

Do you want to produce more efficiently? Processes and flows are key. We optimize these together with you, re-organize them and make sure that you reduce your lead time and save costs. This enables you to implement customized manufacturing and achieve your business goals.

-

Industrialized construction is evolving. Automation, robotics and advanced technology are raising the level of productivity, efficiency and precision for builders in North America.

-

Stiles Machinery is at the forefront of providing technology and machining for producing high quality mass timber. Automated solutions for your mass timber production can increase your manufacturing quality and productivity.

-

Project management services from Stiles make it easy to streamline your entire project— from concept and consultation to integration and implementation.

-

- Online Store

- News

- Careers

- REQUEST INFO

- Home

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

- TECHNICAL SUPPORT

- FIELD SERVICE

- ROUTINE & PREVENTATIVE MAINTENANCE

- REQUEST AN EQUIPMENT MANUAL

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615 Service & Repairs: 616-698-7500 24/7 Parts: 1-800-727-8780

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

- IN-PERSON TRAINING

- CUSTOMIZED COURSES & TRAINING

- STILES UNIVERSITY ONLINE

-

Your solution for workforce development.

- Online Store

- News

- Careers

- FINANCING

- Blog

- REQUEST INFO

- Home

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

- TECHNICAL SUPPORT

- FIELD SERVICE

- ROUTINE & PREVENTATIVE MAINTENANCE

- REQUEST AN EQUIPMENT MANUAL

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615 Service & Repairs: 616-698-7500 24/7 Parts: 1-800-727-8780

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

- IN-PERSON TRAINING

- CUSTOMIZED COURSES & TRAINING

- STILES UNIVERSITY ONLINE

-

Your solution for workforce development.

- Online Store

- News

- Careers

- FINANCING

- Blog

- REQUEST INFO

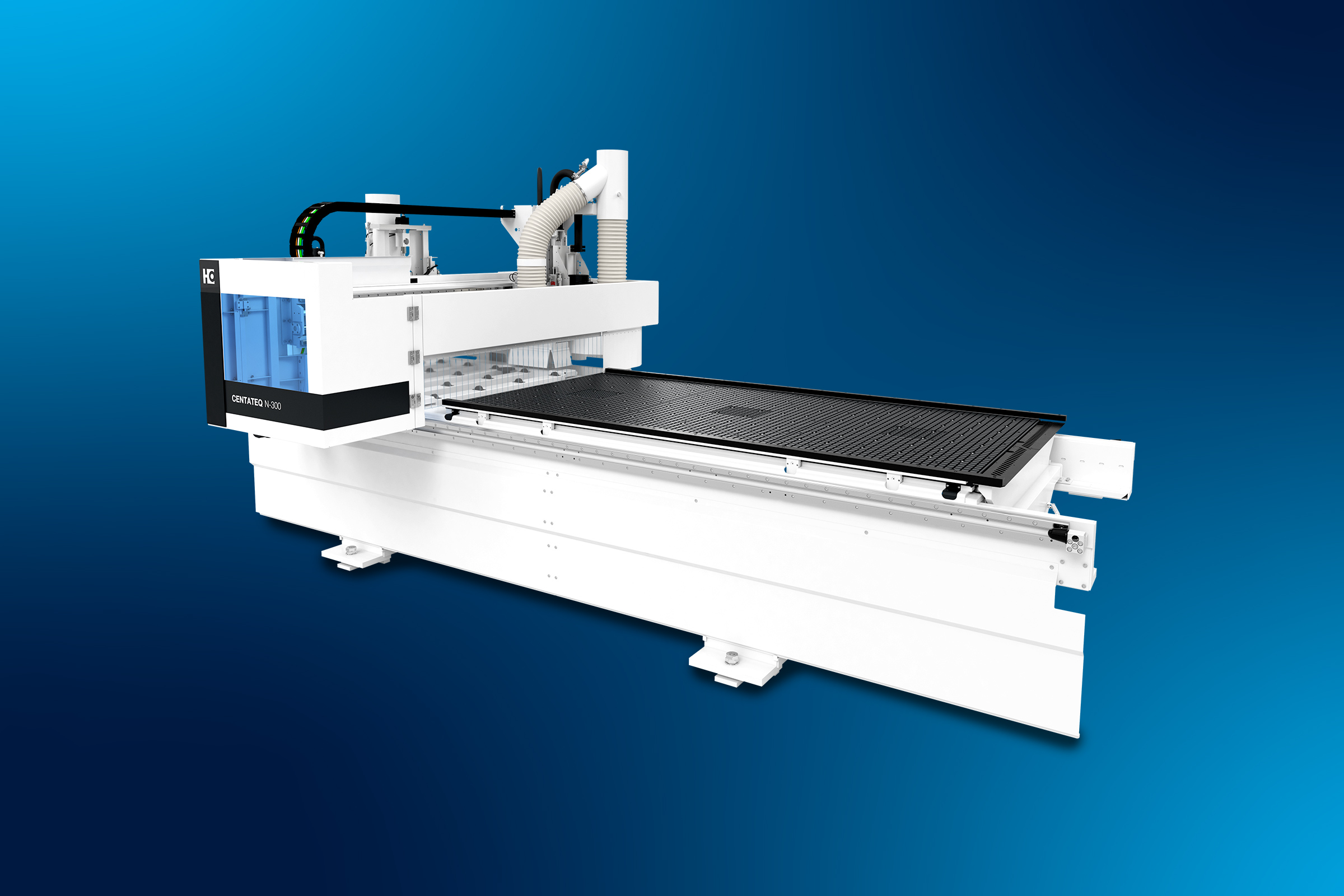

Unlocking the Potential of Wood CNC Machines for Your Next Creative Project

The woodworking industry is undergoing a significant transformation with the advent of advanced technology, particularly the rise of wood CNC machines. According to a recent report by MarketsandMarkets, the global CNC wood cutting machine market is projected to reach USD 3.5 billion by 2025, growing at a CAGR of 6.5%. This surge highlights the increasing adoption of automation and precision in woodworking, enabling creators to enhance their productivity and efficiency.

Wood CNC machines not only facilitate intricate designs and detailed craftsmanship but also allow for the mass production of high-quality wood products. As a result, they are becoming an indispensable tool for both professional artisans and hobbyists alike. Embracing wood CNC technology can unlock new dimensions of creativity, making it possible for individuals to transform their imaginative concepts into tangible masterpieces with unparalleled accuracy and speed.

Understanding the Basics of Wood CNC Machines and Their Functionality

Wood CNC (Computer Numerical Control) machines have revolutionized the woodworking industry by offering precision, efficiency, and versatility necessary for modern creative projects. These machines use computer software to control the movement of tools, allowing artisans to create intricate designs with high accuracy. According to a report by Grand View Research, the global CNC woodworking machine market was valued at approximately $3.92 billion in 2020 and is expected to witness a CAGR of 5.4% from 2021 to 2028, indicating a growing interest in this technology among woodworking enthusiasts and professionals alike.

Understanding the basic functionality of wood CNC machines is crucial for unlocking their potential. Typically, these machines operate through three axes – X, Y, and Z – to carve, engrave, or cut wood materials based on digital designs. This precision enables woodworkers to produce complex shapes and patterns that would be challenging to achieve manually. Research from MarketsandMarkets suggests that the increase in demand for customized wood products and home decor solutions is driving the growth of CNC technology. As a result, learning to operate wood CNC machines can empower creators to bring their imaginative ideas to life with unmatched accuracy and efficiency.

Unlocking the Potential of Wood CNC Machines for Your Next Creative Project

Choosing the Right CNC Machine for Your Creative Project Needs

When selecting the right CNC machine for your creative project, it's essential to consider your specific needs and the type of materials you'll be working with. For wood projects, a CNC router that offers precision and versatility is crucial. Options such as compact desktop models can be ideal for hobbyists and small-scale creators, allowing for intricate designs without taking up too much space. The affordability and user-friendly features of entry-level CNC machines make them accessible for beginners, while advanced models are perfect for seasoned professionals seeking more sophisticated capabilities.

In addition to finding the right machine, you'll want to be aware of the various online CNC services available. Recent comparisons have revealed significant price differences among service providers, highlighting the importance of doing your research. Curated lists of top CNC service options can save time and provide assurance of quality. As a creative, leveraging both the right CNC machine and quality online services can elevate your projects to new heights, enabling you to bring your unique visions to life with precision and creativity.

Essential Software Tools for Designing Wood CNC Projects

The integration of essential software tools in designing wood CNC projects has transformed the way hobbyists and makers approach their creative endeavors. Today’s CNC machines empower users to execute intricate designs with unparalleled precision, enabling the realization of complex components that were once deemed unattainable. The software available for these machines allows for a seamless design process, ensuring that ideas can be translated into tangible results efficiently.

Among the leading software applications for wood CNC projects, 3D modeling tools play a crucial role by enabling users to visualize their designs before production. This not only helps in refining concepts but also in testing the feasibility of projects. Additionally, specialized programs tailored for furniture design streamline the workflow, making it easier to achieve high-quality outcomes. As these software tools continue to evolve, they elevate the creative possibilities for wood CNC enthusiasts, allowing them to unlock their full potential in crafting unique and precise wooden structures.

Unlocking the Potential of Wood CNC Machines for Your Next Creative Project - Essential Software Tools for Designing Wood CNC Projects

| Software Tool | Primary Function | Compatible Formats | Ease of Use | Price Range |

|---|---|---|---|---|

| Fusion 360 | 3D Modeling & CNC Toolpath Generation | .f3d, .dxf, .svg | Medium | $495/year |

| VCarve Pro | CNC Routing and Signmaking | .crv, .dxf, .svg | Easy | $699 one-time |

| SketchUp | 3D Design and Visualization | .skp, .dwg, .dxf | Easy | $299/year |

| Carbide Create | CNC Toolpath Generation for 2D/3D | .c2d, .svg, .dxf | Medium | Free |

| Inkscape | Vector Graphics Editing | .svg, .dxf, .pdf | Easy | Free |

Step-by-Step Guide to Preparing Your Wood for CNC Machining

When embarking on a creative project utilizing wood CNC machines, the preparatory phase is crucial. The first step is selecting the right type of wood, as it significantly influences the machining process and the final outcome. According to a report by the Forest Products Laboratory, hardwoods like oak and maple are often preferred for their durability and aesthetic appeal. Moreover, softwoods such as pine can be ideal for projects requiring intricate designs due to their easier machinability.

Once the wood selection is made, proper preparation is essential. This includes drying and conditioning the wood to an optimal moisture content, typically around 6-8%, as excessive moisture can lead to warping and affect the precision of CNC machining. The Wood Products Council notes that even slight variations in moisture content can impact both the machining quality and the final finish of the product. By following these crucial steps, you can ensure your wood is primed for an efficient and successful CNC experience, paving the way for remarkable creative outcomes.

Once the wood selection is made, proper preparation is essential. This includes drying and conditioning the wood to an optimal moisture content, typically around 6-8%, as excessive moisture can lead to warping and affect the precision of CNC machining. The Wood Products Council notes that even slight variations in moisture content can impact both the machining quality and the final finish of the product. By following these crucial steps, you can ensure your wood is primed for an efficient and successful CNC experience, paving the way for remarkable creative outcomes.

Exploring Creative Project Ideas: What You Can Make with Wood CNC Machines

With the advent of wood CNC machines, the realm of creative projects has been transformed, allowing makers to explore their artistic visions with precision and ease. From personalized home decor to intricate furniture designs, the possibilities are virtually limitless. One popular project idea is creating custom signs that can be tailored for special occasions or business branding. These machines can effortlessly engrave and cut out intricate designs, making it simple to add a personal touch to any space.

In addition to signage, wood CNC machines are fantastic for crafting unique kitchen accessories, such as cutting boards or utensil holders. By utilizing various wood types and finishes, creators can produce functional yet aesthetically pleasing items that elevate the culinary experience. Moreover, these machines enable the crafting of bespoke jewelry organizers or children's educational toys, showcasing the versatility of wood in everyday life. The ability to translate imaginative designs into tangible products not only enhances craftsmanship but also provides a rewarding avenue for expressing creativity.