- Home

-

-

-

Stiles Enhancement Technologies

-

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

-

-

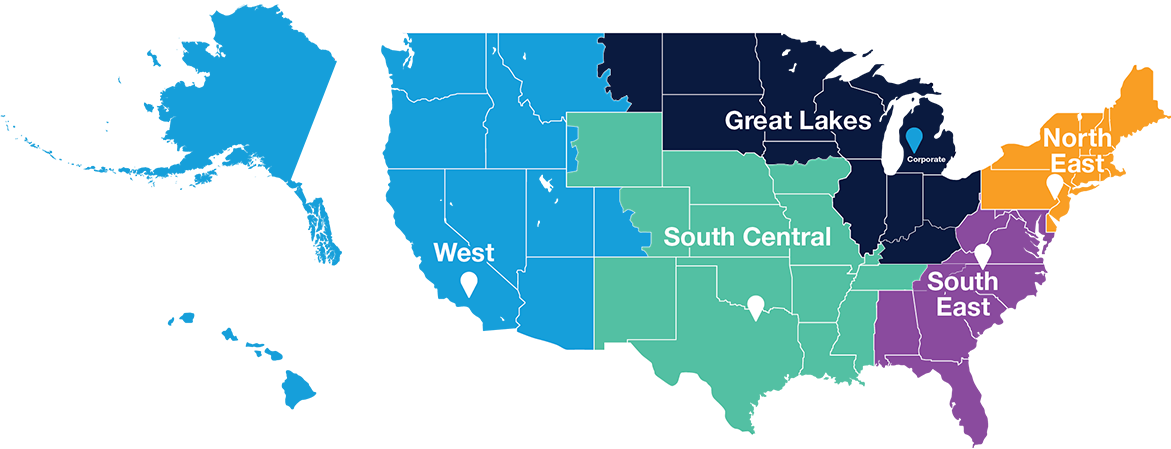

- Stiles Machinery hosts a national network of five regional service centers and nationwide force of over 200 Field Service Representatives put the industry’s best service where it belongs – close to you.

- Routine & Preventative Maintenance

- Technical Support & Diagnostics

- Field Service

- Request an Equipment Manual

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615

Service & Repairs: 616-698-7500

24/7 Parts: 1-800-727-8780

sale@inlandmachineokc.com

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

-

With a customized Stiles University course, we can provide expert training for your team, on-location. Whether it's programming, operation or maintenance, we want to help you train your personnel to meet your production goals efficiently and effectively.

-

Experience the trusted workforce development training and machinery knowledge you rely on from Stiles University, now at your convenience. With technology changing every day and new methods being developed constantly, Stiles University Online has the latest information and training content available at your fingertips.

-

Your solution for workforce development.

616-698-7500

-

-

-

Do you want to produce more efficiently? Processes and flows are key. We optimize these together with you, re-organize them and make sure that you reduce your lead time and save costs. This enables you to implement customized manufacturing and achieve your business goals.

-

Industrialized construction is evolving. Automation, robotics and advanced technology are raising the level of productivity, efficiency and precision for builders in North America.

-

Stiles Machinery is at the forefront of providing technology and machining for producing high quality mass timber. Automated solutions for your mass timber production can increase your manufacturing quality and productivity.

-

Project management services from Stiles make it easy to streamline your entire project— from concept and consultation to integration and implementation.

-

- Online Store

- News

- Careers

- REQUEST INFO

- Home

-

-

-

Stiles Enhancement Technologies

-

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

-

-

- Stiles Machinery hosts a national network of five regional service centers and nationwide force of over 200 Field Service Representatives put the industry’s best service where it belongs – close to you.

- Routine & Preventative Maintenance

- Technical Support & Diagnostics

- Field Service

- Request an Equipment Manual

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615

Service & Repairs: 616-698-7500

24/7 Parts: 1-800-727-8780

sale@inlandmachineokc.com

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

-

With a customized Stiles University course, we can provide expert training for your team, on-location. Whether it's programming, operation or maintenance, we want to help you train your personnel to meet your production goals efficiently and effectively.

-

Experience the trusted workforce development training and machinery knowledge you rely on from Stiles University, now at your convenience. With technology changing every day and new methods being developed constantly, Stiles University Online has the latest information and training content available at your fingertips.

-

Your solution for workforce development.

616-698-7500

-

-

-

Do you want to produce more efficiently? Processes and flows are key. We optimize these together with you, re-organize them and make sure that you reduce your lead time and save costs. This enables you to implement customized manufacturing and achieve your business goals.

-

Industrialized construction is evolving. Automation, robotics and advanced technology are raising the level of productivity, efficiency and precision for builders in North America.

-

Stiles Machinery is at the forefront of providing technology and machining for producing high quality mass timber. Automated solutions for your mass timber production can increase your manufacturing quality and productivity.

-

Project management services from Stiles make it easy to streamline your entire project— from concept and consultation to integration and implementation.

-

- Online Store

- News

- Careers

- REQUEST INFO

- Home

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

- TECHNICAL SUPPORT

- FIELD SERVICE

- ROUTINE & PREVENTATIVE MAINTENANCE

- REQUEST AN EQUIPMENT MANUAL

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615 Service & Repairs: 616-698-7500 24/7 Parts: 1-800-727-8780

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

- IN-PERSON TRAINING

- CUSTOMIZED COURSES & TRAINING

- STILES UNIVERSITY ONLINE

-

Your solution for workforce development.

- Online Store

- News

- Careers

- FINANCING

- Blog

- REQUEST INFO

- Home

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

- TECHNICAL SUPPORT

- FIELD SERVICE

- ROUTINE & PREVENTATIVE MAINTENANCE

- REQUEST AN EQUIPMENT MANUAL

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615 Service & Repairs: 616-698-7500 24/7 Parts: 1-800-727-8780

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

- IN-PERSON TRAINING

- CUSTOMIZED COURSES & TRAINING

- STILES UNIVERSITY ONLINE

-

Your solution for workforce development.

- Online Store

- News

- Careers

- FINANCING

- Blog

- REQUEST INFO

Unlocking Creativity: How CNC Wood Cutting Machines Transform Custom Furniture Design

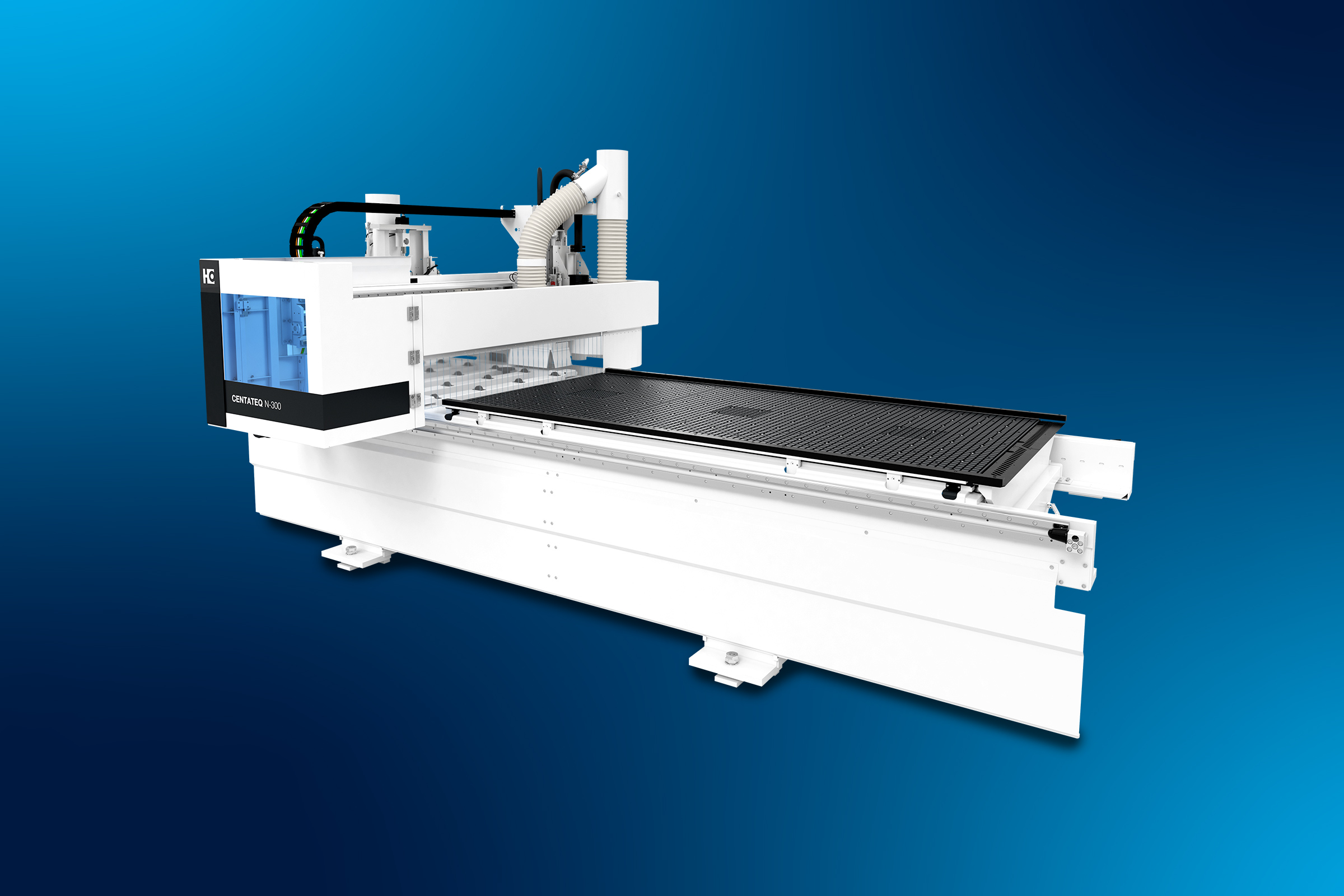

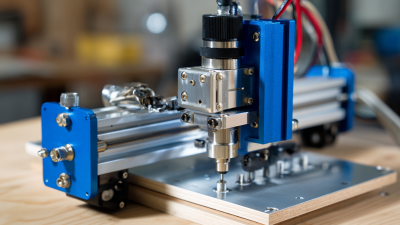

In the realm of custom furniture design, creativity knows no bounds, especially with the advent of advanced technologies like the CNC wood cutting machine. These innovative tools have revolutionized the way designers conceptualize and create bespoke pieces, integrating precision engineering with artistic expression. The ability to transform a simple design into a stunning, intricate work of art has made CNC wood cutting machines essential in the modern workshop, enabling artisans to push the limits of their imagination.

As we dive deeper into the transformative impact of CNC wood cutting machines, we will explore the top five ways these remarkable devices are unlocking new possibilities in furniture design. From enhancing accuracy and efficiency to fostering unique artistic expressions, these machines not only simplify the manufacturing process but also empower designers to experiment with unconventional ideas. Join us as we examine how these technological advancements are shaping the future of custom furniture, redefining what is possible in the world of woodworking and design.

The Evolution of Custom Furniture Design Through CNC Technology

The evolution of custom furniture design has been dramatically influenced by the advent of CNC (Computer Numerical Control) technology. Previously, creating bespoke pieces required extensive manual labor, limiting designers' ability to explore innovative concepts. With CNC wood cutting machines, designers can now translate intricate digital designs into precise physical structures, enhancing both creativity and efficiency. This technology allows for exact replication of complex patterns, enabling a level of detail and customization that was once unattainable.

Furthermore, CNC technology streamlines the production process, significantly reducing lead times. The machines can work continuously with minimal supervision, which not only boosts productivity but also allows artisans to focus more on the creative aspect of their work rather than mundane tasks. As a result, custom furniture designers are empowered to push boundaries, experiment with unconventional materials, and offer clients unique, personalized solutions that cater to their specific tastes and needs. This shift marks a significant milestone in the furniture industry, paving the way for a new era of creativity and functionality in design.

Unlocking Creativity: CNC Wood Cutting Machines in Custom Furniture Design

This chart illustrates the significant reduction in time required for furniture design using CNC technology compared to traditional methods. With CNC machines, designers can create complex custom pieces in a fraction of the time, enhancing creativity and efficiency in the furniture industry.

Key Features of CNC Wood Cutting Machines That Enhance Creativity

CNC wood cutting machines are revolutionizing custom furniture design by providing unparalleled precision and flexibility. These innovative tools enable craftsmen and designers to explore intricate patterns and personalized designs that were previously challenging or impossible to achieve with traditional woodworking methods.

The key features of CNC machines include advanced software integration, multi-axis cutting capabilities, and high-speed operation, which together enhance creativity in furniture making.

With software that allows for easy modifications and detailed visualizations, designers can quickly translate ideas into reality. The ability to cut complex shapes accurately reduces material waste and streamlines the production process. Additionally, the consistency achieved through CNC machining ensures that each piece of custom furniture meets high-quality standards, making it easier for designers to replicate successful designs or produce limited runs of bespoke items. As the global market for wood processing equipment continues to expand, the impact of CNC technology on the furniture industry is set to grow, unlocking new avenues for creative exploration.

Design Tips for Maximizing CNC Machine Capabilities in Furniture Making

When working with CNC wood cutting machines in custom furniture design, maximizing their capabilities can significantly enhance the creative process. One essential tip is to embrace the versatility of design software. Utilizing advanced CAD (Computer-Aided Design) programs allows you to create intricate patterns and layouts that leverage the precise cutting abilities of CNC technology. Explore various templates and experiment with different materials to fully exploit the machine's potential, ensuring that your designs are both unique and functional.

Another crucial aspect is to consider the characteristics of the wood being used. Different types of wood can yield varying results when cut, so it’s important to select materials that complement your design intentions. For instance, hardwoods may provide the desired durability and aesthetic appeal, while softer woods can offer greater ease of manipulation and intricate detailing. Additionally, incorporating layered designs can add depth and dimension to furniture pieces, making them stand out while efficiently utilizing CNC cutting techniques. By harmonizing material selection with innovative design strategies, furniture makers can truly unlock the transformative power of CNC machines.

Case Studies: Successful Custom Furniture Projects with CNC Techniques

CNC wood cutting machines have revolutionized the landscape of custom furniture design, enabling makers and designers to push boundaries like never before. In recent case studies, various successful projects highlight the versatility and precision these machines offer. For instance, a local startup created a series of bespoke dining tables featuring intricate geometric patterns that were impossible to achieve through traditional woodworking techniques. The CNC machine allowed for precise cuts that ensured consistency and minimized waste, showcasing how technology can harmonize with craftsmanship.

Tips for utilizing CNC techniques effectively include investing time in good software that optimizes designs for CNC cutting. This can significantly enhance the workflow, ensuring that designs translate well from concept to reality. Additionally, choosing the right materials is crucial; hardwoods not only hold up better structurally but also provide a more refined aesthetic. By incorporating CNC technology into their work, designers can expand their creative potential and produce luxurious, custom furniture that meets the demands of modern homeowners.

Future Trends in CNC Wood Cutting and Its Impact on Furniture Design

The landscape of furniture design is evolving with the advancement of CNC wood cutting technology. In recent years, designers have begun to harness the precision and flexibility offered by these machines, enabling them to explore complex shapes and intricate patterns that were once unattainable through traditional woodworking methods. This shift not only enhances the aesthetic appeal of custom furniture but also opens new avenues for sustainable practices by optimizing material usage and reducing waste.

Looking ahead, future trends in CNC wood cutting are poised to further redefine the furniture industry. With the integration of smart technology and automation, we can expect an increased demand for personalized and adaptive furniture solutions that cater to individual customer preferences. Additionally, as consumers become more environmentally conscious, CNC machines are likely to embrace eco-friendly materials and methods, ensuring that future designs align with sustainable living. Ultimately, these innovations will not only elevate the craftsmanship of custom furniture but also create a more responsive market that anticipates and meets the diverse needs of modern consumers.

Related Posts

-

Exploring the Amazing World of CNC Routers for DIY Enthusiasts

-

The Ultimate Guide to Choosing the Best Sanding Machine for Your DIY Projects

-

Exploring the Future of Manufacturing: How CNC Machines are Revolutionizing Production Techniques

-

The Future of Manufacturing How CNC Machining Parts Revolutionize Production Processes

-

Unlocking Precision: How Small CNC Machines Revolutionize DIY Projects and Prototyping

-

The Ultimate Guide to Choosing the Perfect Sanding Machine for Your DIY Projects