- Home

-

-

-

Stiles Enhancement Technologies

-

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

-

-

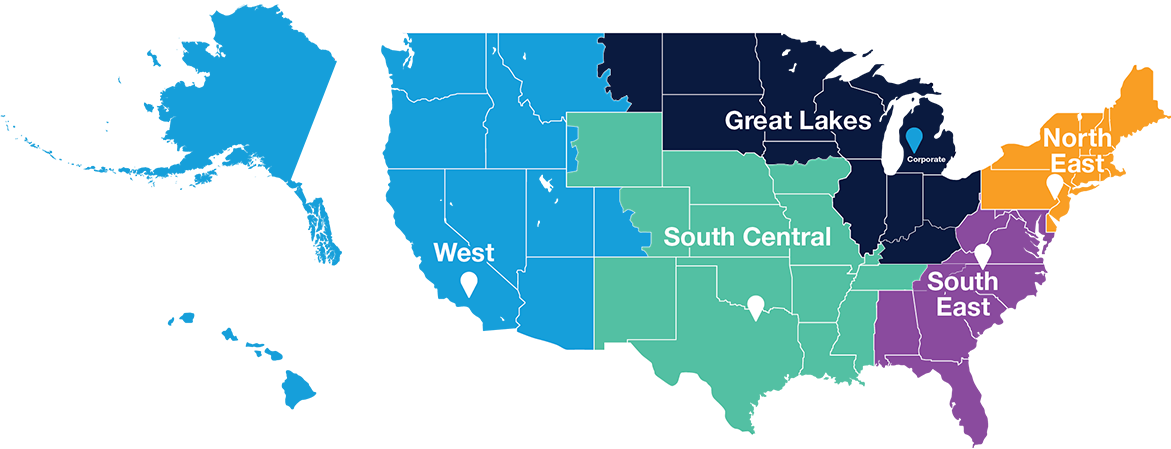

- Stiles Machinery hosts a national network of five regional service centers and nationwide force of over 200 Field Service Representatives put the industry’s best service where it belongs – close to you.

- Routine & Preventative Maintenance

- Technical Support & Diagnostics

- Field Service

- Request an Equipment Manual

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615

Service & Repairs: 616-698-7500

24/7 Parts: 1-800-727-8780

sale@inlandmachineokc.com

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

-

With a customized Stiles University course, we can provide expert training for your team, on-location. Whether it's programming, operation or maintenance, we want to help you train your personnel to meet your production goals efficiently and effectively.

-

Experience the trusted workforce development training and machinery knowledge you rely on from Stiles University, now at your convenience. With technology changing every day and new methods being developed constantly, Stiles University Online has the latest information and training content available at your fingertips.

-

Your solution for workforce development.

616-698-7500

-

-

-

Do you want to produce more efficiently? Processes and flows are key. We optimize these together with you, re-organize them and make sure that you reduce your lead time and save costs. This enables you to implement customized manufacturing and achieve your business goals.

-

Industrialized construction is evolving. Automation, robotics and advanced technology are raising the level of productivity, efficiency and precision for builders in North America.

-

Stiles Machinery is at the forefront of providing technology and machining for producing high quality mass timber. Automated solutions for your mass timber production can increase your manufacturing quality and productivity.

-

Project management services from Stiles make it easy to streamline your entire project— from concept and consultation to integration and implementation.

-

- Online Store

- News

- Careers

- REQUEST INFO

- Home

-

-

-

Stiles Enhancement Technologies

-

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

-

-

- Stiles Machinery hosts a national network of five regional service centers and nationwide force of over 200 Field Service Representatives put the industry’s best service where it belongs – close to you.

- Routine & Preventative Maintenance

- Technical Support & Diagnostics

- Field Service

- Request an Equipment Manual

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615

Service & Repairs: 616-698-7500

24/7 Parts: 1-800-727-8780

sale@inlandmachineokc.com

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

-

With a customized Stiles University course, we can provide expert training for your team, on-location. Whether it's programming, operation or maintenance, we want to help you train your personnel to meet your production goals efficiently and effectively.

-

Experience the trusted workforce development training and machinery knowledge you rely on from Stiles University, now at your convenience. With technology changing every day and new methods being developed constantly, Stiles University Online has the latest information and training content available at your fingertips.

-

Your solution for workforce development.

616-698-7500

-

-

-

Do you want to produce more efficiently? Processes and flows are key. We optimize these together with you, re-organize them and make sure that you reduce your lead time and save costs. This enables you to implement customized manufacturing and achieve your business goals.

-

Industrialized construction is evolving. Automation, robotics and advanced technology are raising the level of productivity, efficiency and precision for builders in North America.

-

Stiles Machinery is at the forefront of providing technology and machining for producing high quality mass timber. Automated solutions for your mass timber production can increase your manufacturing quality and productivity.

-

Project management services from Stiles make it easy to streamline your entire project— from concept and consultation to integration and implementation.

-

- Online Store

- News

- Careers

- REQUEST INFO

- Home

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

- TECHNICAL SUPPORT

- FIELD SERVICE

- ROUTINE & PREVENTATIVE MAINTENANCE

- REQUEST AN EQUIPMENT MANUAL

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615 Service & Repairs: 616-698-7500 24/7 Parts: 1-800-727-8780

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

- IN-PERSON TRAINING

- CUSTOMIZED COURSES & TRAINING

- STILES UNIVERSITY ONLINE

-

Your solution for workforce development.

- Online Store

- News

- Careers

- FINANCING

- Blog

- REQUEST INFO

- Home

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

- TECHNICAL SUPPORT

- FIELD SERVICE

- ROUTINE & PREVENTATIVE MAINTENANCE

- REQUEST AN EQUIPMENT MANUAL

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615 Service & Repairs: 616-698-7500 24/7 Parts: 1-800-727-8780

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

- IN-PERSON TRAINING

- CUSTOMIZED COURSES & TRAINING

- STILES UNIVERSITY ONLINE

-

Your solution for workforce development.

- Online Store

- News

- Careers

- FINANCING

- Blog

- REQUEST INFO

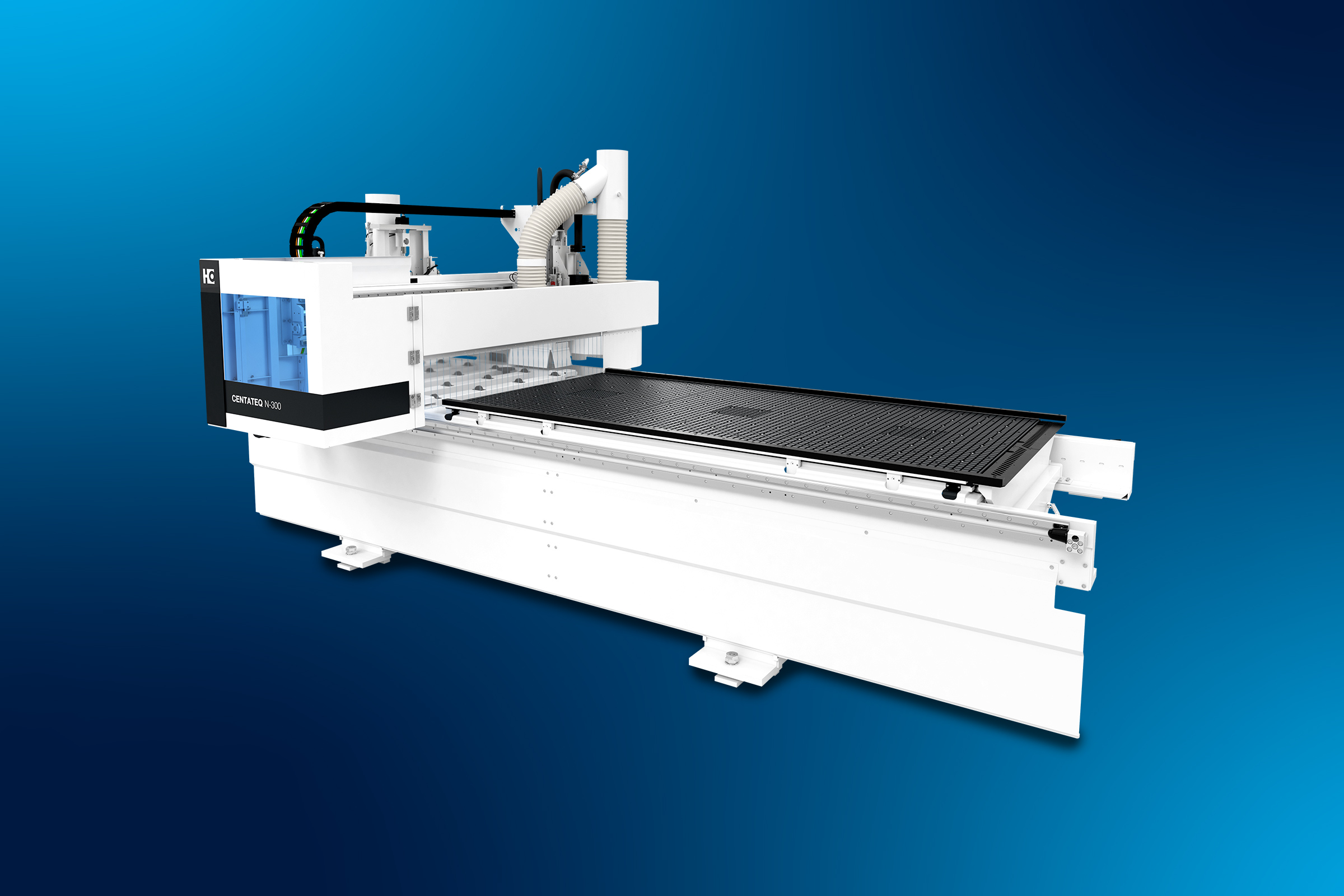

2026 Top Woodworking CNC Machines: Features, Benefits, and Buying Guide

In the ever-evolving world of woodworking, the rise of the woodworking CNC machine marks a significant shift. Expert John Smith, a veteran in the industry, once stated, "CNC technology revolutionizes how we approach woodworking." This advancement offers precision and efficiency that traditional methods cannot match.

Woodworking CNC machines automate cutting, shaping, and engraving. They enable craftsmen to turn ideas into reality faster. Yet, with innovation comes complexity. Choosing the right machine can be overwhelming. Features vary, and costs can escalate quickly. Buyers must balance their needs and budgets.

Additionally, while CNC machines offer incredible capabilities, they may not suit every project. Some artisans still cherish hands-on techniques. The blend of technology and tradition raises important questions. Is fully automated woodworking truly the future? It's a topic worth pondering.

Top Features to Look for in CNC Woodworking Machines

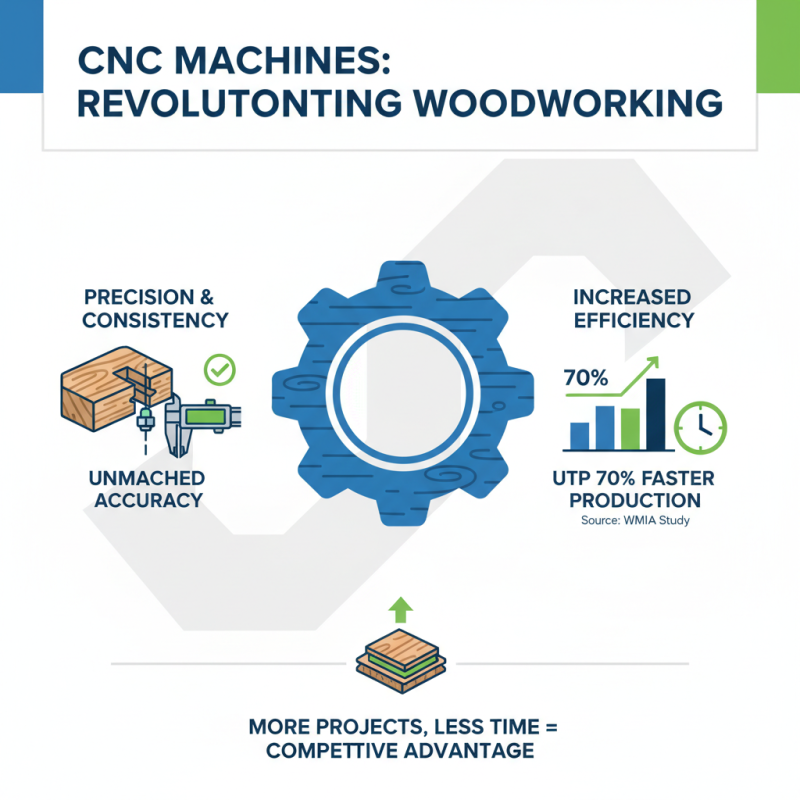

When choosing a CNC woodworking machine, several key features stand out. Precision is paramount. Many machines offer accuracy within 0.001 inches. This precision leads to cleaner cuts and better finishes, crucial for high-quality woodworking projects. A report from the Woodworking Machinery Industry Association indicates that accuracy can increase product value by up to 20%.

Another important aspect is the machine’s software compatibility. Advanced CNC machines support various design software, allowing for easy integration into design workflows. User-friendly interfaces are also essential. Many users prefer machines that require minimal training. A study shows that over 70% of operators value intuitive controls.

Portability and size may not get enough attention. Smaller workshops often struggle with space. A compact machine can enhance workflow without sacrificing functionality. Some users find it challenging to adapt to smaller work areas. Additionally, maintenance needs can vary widely. Regular upkeep is necessary for efficient operation. Operators must reflect on how maintenance impacts productivity. This consideration can sometimes be overlooked. Ultimately, these features greatly influence the user experience and the quality of produced work.

Benefits of Using CNC Machines in Woodworking Projects

CNC machines have revolutionized woodworking. They allow for precision and consistency that hand tools simply can’t match. A study by the Woodworking Machinery Industry Association indicates that CNC technology can increase production efficiency by up to 70%. This means more projects can be completed in less time, offering a significant advantage in competitive markets.

The flexibility of CNC machines is remarkable. They can handle intricate designs with ease, which is crucial for custom woodworking projects. According to industry reports, more than 60% of woodworkers now use CNC machines for their ability to create complex shapes and patterns. However, reliance on these machines can lead to a lack of hands-on skill. Some craftsmen worry that essential woodworking techniques may be lost over time.

The accuracy of CNC machines is not always perfect. Slight misalignments can occur, requiring adjustments and reflections on the work process. This forces woodworkers to double-check their designs and settings. While CNC machines offer benefits, they should complement traditional methods, not replace them. Blending both techniques may yield the best results, merging speed with craftsmanship.

A Comprehensive Buying Guide for CNC Woodworking Machines

When considering a CNC woodworking machine, think about your specific needs. These machines come with varying features and capabilities. Some are designed for intricate details, while others excel in speed and efficiency. You must identify what matters most for your projects. Will you be crafting fine furniture or building large structures? Your answer impacts your choice.

Budget is another critical factor. Prices can range significantly, and it’s easy to overspend. Look for models that balance cost with necessary features. Sometimes, the most expensive machine isn't the best fit. Consider customer support, software compatibility, and ease of use as well. It's crucial to evaluate these elements carefully. An affordable machine with excellent support may serve you better than a high-end option without assistance.

Finally, don't forget to read reviews from actual users. Sometimes, what appears perfect on paper may not perform well in practice. Gather feedback on durability and precision. Reflect on your working style. Will you need more than one machine in the future? Understanding these factors will lead you to a more informed decision.

Best Brands and Models of CNC Machines for Woodworkers

Choosing a CNC machine for woodworking can be challenging. Many woodworkers face a myriad of options. Each model offers unique features, which can be overwhelming. An ideal CNC machine should provide precision, speed, and ease of use. It's essential to identify your specific needs. Do you require detailed carvings or simple cuts? Clarity on your requirements will lead to a suitable choice.

When exploring brands and models, consider machine size and capability. Some models excel in handling large wooden pieces. Others may be designed for intricate details on smaller items. Always check reviews and user feedback; they often reveal strengths and weaknesses. A reputable brand doesn’t guarantee perfection. Every machine has quirks and flaws. Users frequently report software glitches or inconsistent performance. It's important to choose wisely, based on thorough research and personal experience.

Budget is another crucial factor. High-end machines often boast advanced features. However, they may not always be the best fit. Some budget-friendly models can still deliver remarkable results with the right techniques. Experimenting with various setups can lead to unexpected discoveries. Be open to learning and adapting your methods. This journey will help refine your skills as a woodworker.

Maintenance Tips for Longevity of CNC Woodworking Machines

CNC woodworking machines are valuable tools in any workshop. To ensure they last, proper maintenance is essential. Regular cleaning keeps the machine free from dust and debris. Neglecting this task can lead to malfunctioning parts. Always use a soft brush or compressed air to clear out tough spots.

Another important maintenance tip is lubrication. Every moving part needs the right amount of lubrication. Too little can cause wear and tear. Too much can attract grime. Check manufacturer recommendations for specific areas to lubricate. Watch for performance changes; that can indicate a need for more attention.

Calibration is crucial. Machines may drift from their settings over time. Regular checks ensure precise cuts. If you notice inconsistencies, calibrate immediately. A well-calibrated machine improves productivity and quality. Keeping a log of maintenance activities can help track issues and avoid future problems.

2026 Top Woodworking CNC Machines: Performance Comparison

This chart visualizes the cutting speed of various woodworking CNC machines in 2026. The performance comparison helps users evaluate which machine meets their woodworking needs effectively.

Related Posts

-

Top Wood CNC Machine Benefits for Your Business and Creative Projects

-

Unlocking Creativity: How CNC Wood Cutting Machines Transform Custom Furniture Design

-

Top 10 Wood Carving Machines for Professional and Hobby Use

-

Top 10 CNC Machine Types You Need to Know for Precision Machining

-

Best CNC Router Machine for Beginners and Professionals in 2023

-

10 Essential Tips for Maximizing Efficiency with Your CNC Mill