- Home

-

-

-

Stiles Enhancement Technologies

-

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

-

-

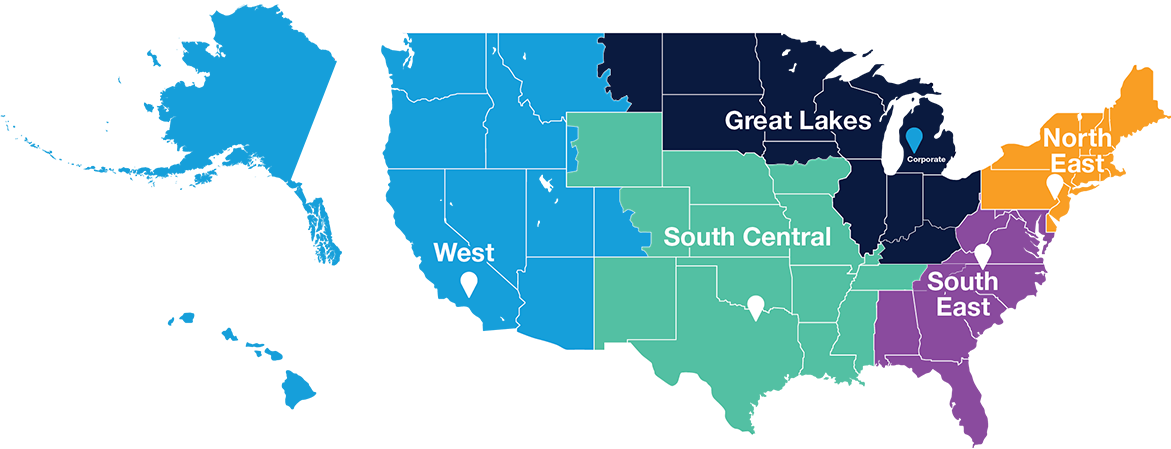

- Stiles Machinery hosts a national network of five regional service centers and nationwide force of over 200 Field Service Representatives put the industry’s best service where it belongs – close to you.

- Routine & Preventative Maintenance

- Technical Support & Diagnostics

- Field Service

- Request an Equipment Manual

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615

Service & Repairs: 616-698-7500

24/7 Parts: 1-800-727-8780

sale@inlandmachineokc.com

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

-

With a customized Stiles University course, we can provide expert training for your team, on-location. Whether it's programming, operation or maintenance, we want to help you train your personnel to meet your production goals efficiently and effectively.

-

Experience the trusted workforce development training and machinery knowledge you rely on from Stiles University, now at your convenience. With technology changing every day and new methods being developed constantly, Stiles University Online has the latest information and training content available at your fingertips.

-

Your solution for workforce development.

616-698-7500

-

-

-

Do you want to produce more efficiently? Processes and flows are key. We optimize these together with you, re-organize them and make sure that you reduce your lead time and save costs. This enables you to implement customized manufacturing and achieve your business goals.

-

Industrialized construction is evolving. Automation, robotics and advanced technology are raising the level of productivity, efficiency and precision for builders in North America.

-

Stiles Machinery is at the forefront of providing technology and machining for producing high quality mass timber. Automated solutions for your mass timber production can increase your manufacturing quality and productivity.

-

Project management services from Stiles make it easy to streamline your entire project— from concept and consultation to integration and implementation.

-

- Online Store

- News

- Careers

- REQUEST INFO

- Home

-

-

-

Stiles Enhancement Technologies

-

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

-

-

- Stiles Machinery hosts a national network of five regional service centers and nationwide force of over 200 Field Service Representatives put the industry’s best service where it belongs – close to you.

- Routine & Preventative Maintenance

- Technical Support & Diagnostics

- Field Service

- Request an Equipment Manual

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615

Service & Repairs: 616-698-7500

24/7 Parts: 1-800-727-8780

sale@inlandmachineokc.com

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

-

With a customized Stiles University course, we can provide expert training for your team, on-location. Whether it's programming, operation or maintenance, we want to help you train your personnel to meet your production goals efficiently and effectively.

-

Experience the trusted workforce development training and machinery knowledge you rely on from Stiles University, now at your convenience. With technology changing every day and new methods being developed constantly, Stiles University Online has the latest information and training content available at your fingertips.

-

Your solution for workforce development.

616-698-7500

-

-

-

Do you want to produce more efficiently? Processes and flows are key. We optimize these together with you, re-organize them and make sure that you reduce your lead time and save costs. This enables you to implement customized manufacturing and achieve your business goals.

-

Industrialized construction is evolving. Automation, robotics and advanced technology are raising the level of productivity, efficiency and precision for builders in North America.

-

Stiles Machinery is at the forefront of providing technology and machining for producing high quality mass timber. Automated solutions for your mass timber production can increase your manufacturing quality and productivity.

-

Project management services from Stiles make it easy to streamline your entire project— from concept and consultation to integration and implementation.

-

- Online Store

- News

- Careers

- REQUEST INFO

- Home

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

- TECHNICAL SUPPORT

- FIELD SERVICE

- ROUTINE & PREVENTATIVE MAINTENANCE

- REQUEST AN EQUIPMENT MANUAL

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615 Service & Repairs: 616-698-7500 24/7 Parts: 1-800-727-8780

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

- IN-PERSON TRAINING

- CUSTOMIZED COURSES & TRAINING

- STILES UNIVERSITY ONLINE

-

Your solution for workforce development.

- Online Store

- News

- Careers

- FINANCING

- Blog

- REQUEST INFO

- Home

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

- TECHNICAL SUPPORT

- FIELD SERVICE

- ROUTINE & PREVENTATIVE MAINTENANCE

- REQUEST AN EQUIPMENT MANUAL

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615 Service & Repairs: 616-698-7500 24/7 Parts: 1-800-727-8780

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

- IN-PERSON TRAINING

- CUSTOMIZED COURSES & TRAINING

- STILES UNIVERSITY ONLINE

-

Your solution for workforce development.

- Online Store

- News

- Careers

- FINANCING

- Blog

- REQUEST INFO

Top 10 CNC Machine Types You Need to Know for Precision Machining

In the realm of precision machining, understanding the various types of CNC (Computer Numerical Control) machines is crucial for achieving optimal results. According to a report by MarketsandMarkets, the CNC machine market is projected to reach USD 117.18 billion by 2026, highlighting the growing importance of automated manufacturing technologies across various industries. As industries increasingly embrace automation, the demand for precise and efficient machining solutions continues to rise, underscoring the need for professionals to familiarize themselves with different CNC machine types.

Experts in the field, like Dr. Mike Johnson, a leading researcher in CNC technology, emphasize the critical role of these machines in modern manufacturing. Dr. Johnson states, “CNC machines not only enhance productivity but also ensure precision in every aspect of machining processes.” This sentiment reflects the industry’s shift towards more sophisticated and versatile equipment, allowing machinists to execute intricate designs with unparalleled accuracy. As we explore the top 10 CNC machine types, it becomes evident that each type offers unique advantages, enabling manufacturers to push the boundaries of innovation and efficiency.

Types of CNC Machines and Their Applications in Precision Machining

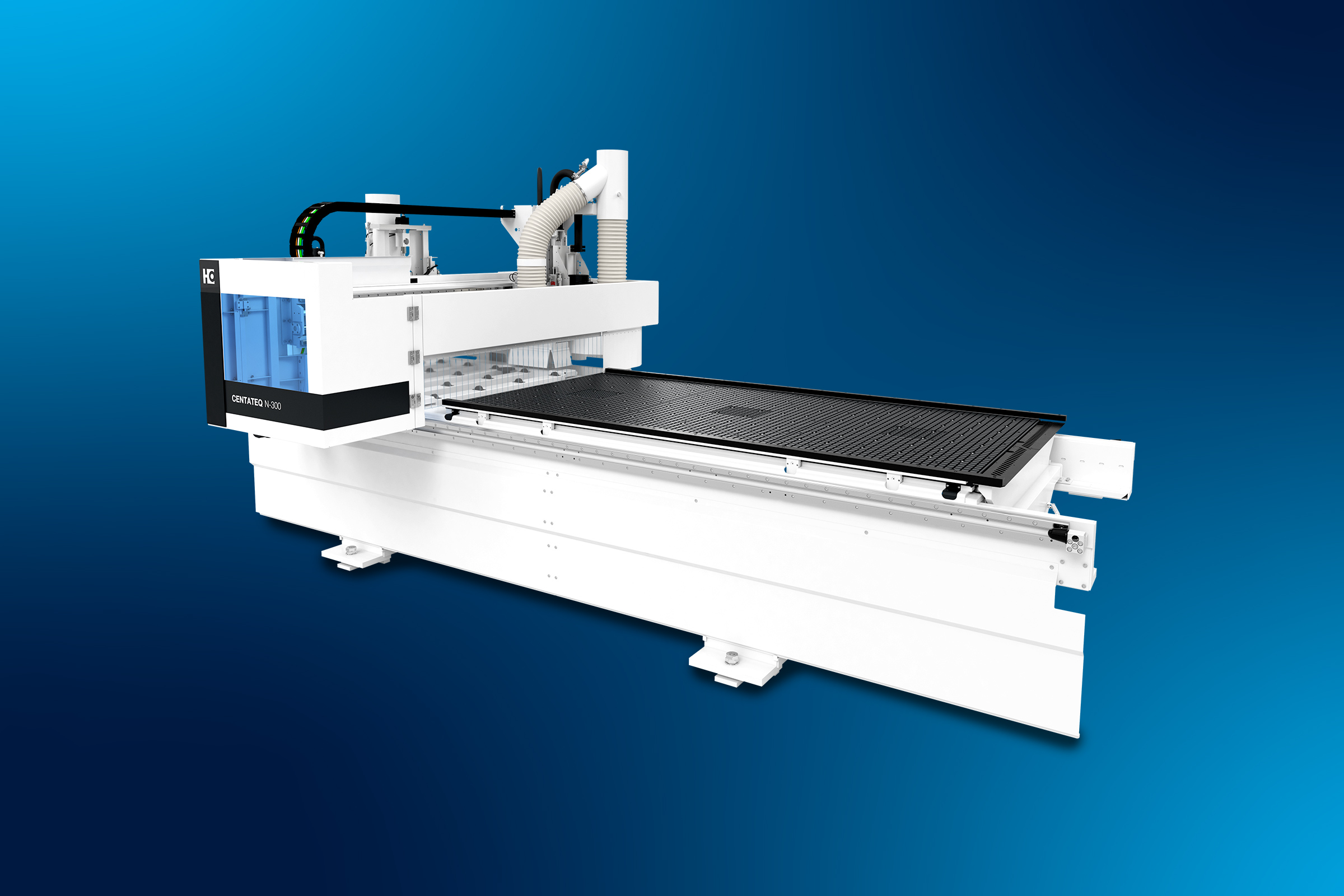

CNC (Computer Numerical Control) machines are instrumental in the realm of precision machining, offering a level of accuracy and repeatability that traditional machining methods struggle to match. Among the various types of CNC machines, CNC mills, lathes, and routers are the most prevalent. CNC mills utilize rotary cutters to remove material, allowing for complex shapes and detailed designs. According to a report by Mordor Intelligence, the global CNC machining market is projected to grow at a CAGR of 6.2% from 2021 to 2026, driven by the increasing demand for precision machined components across various industries, including aerospace and automotive.

Another vital machine type is the CNC lathe, which is used primarily for cylindrical parts by rotating the workpiece against a cutting tool. The use of CNC lathes has surged due to their efficiency in producing components with tight tolerances, essential in sectors such as medical device manufacturing, where even minor deviations can lead to significant issues. Additionally, CNC routers have gained popularity in woodworking and plastics applications, offering the ability to engrave, cut, and shape materials with high precision. The adoption of CNC routers in industries is expected to witness substantial growth as advancements in technology reduce operational costs and enhance production speeds, making them an attractive option for businesses looking to optimize their manufacturing processes.

Key Features and Advantages of CNC Machining Technologies

CNC (Computer Numerical Control) machining has revolutionized the manufacturing industry with its precision and efficiency. One of the key features of CNC machining technologies is their ability to produce highly accurate and complex geometries. By utilizing computer programming, CNC machines can follow precise instructions to create intricate parts that meet stringent tolerances. This level of consistency and repeatability is essential in industries such as aerospace, automotive, and medical, where even the slightest deviation can result in significant issues.

Another advantage of CNC machining is its versatility. CNC machines can accommodate a wide range of materials, including metals, plastics, and composites. This adaptability allows manufacturers to switch between different production runs without the need for extensive reconfiguration, saving time and reducing costs. Additionally, CNC technology often includes advanced features like automated tool changers and multi-axis capabilities, further enhancing productivity and efficiency. Overall, the key features and advantages of CNC machining technologies make them indispensable for achieving high-quality precision machining.

Comparison of CNC Lathes, Mills, and Routers for Precision Tasks

CNC lathes, mills, and routers are essential tools in the realm of precision machining, each serving unique functions that cater to various manufacturing needs. CNC lathes are particularly adept at shaping and cutting cylindrical pieces, utilizing a rotating workpiece against a stationary cutting tool. This process is highly effective for producing components with round geometries, such as shafts and fittings, making lathes indispensable in industries requiring uniformity and precision.

On the other hand, CNC mills excel in three-dimensional machining tasks, capable of cutting, drilling, and shaping materials in multiple directions. This versatility allows for intricate designs and complex geometries, facilitating the production of parts with various profiles. Meanwhile, CNC routers are typically employed for cutting softer materials such as wood and plastics. They can handle large sheets and create detailed designs efficiently, making them ideal for woodworking and decorative applications. When choosing between these machines, manufacturers must consider the specific material, desired precision, and complexity of the parts to determine the most suitable CNC technology for their projects.

Top 10 CNC Machine Types You Need to Know for Precision Machining

| Machine Type | Main Features | Precision (mm) | Common Applications |

|---|---|---|---|

| CNC Lathe | Rotary cutting tool, suitable for cylindrical parts | 0.01 | Shafts, bushings, and other cylindrical components |

| CNC Mill | Uses rotating cutting tools to remove material | 0.005 | Flat surfaces, complex shapes, and molds |

| CNC Router | Cutting tool for softer materials like wood and plastics | 0.1 | Furniture, signage, and decorative elements |

| CNC Plasma Cutter | Uses a plasma torch to cut metals | 0.5 | Sheet metal fabrication and metal art |

| CNC Wire EDM | Electrical discharge machining using a thin wire | 0.005 | High precision parts, tooling, and dies |

| CNC Laser Cutter | Uses a laser beam to cut or engrave materials | 0.1 | Engraving, cutting sheet materials like acrylics |

| CNC 5-Axis Mill | Allows for complex geometries with multiple angles | 0.005 | Aerospace components, molds, and medical devices |

| CNC Vertical Machining Center | Multi-purpose machining center for vertical milling | 0.01 | Machining various metals and alloys |

| CNC Horizontal Machining Center | Excellent chip removal, high productivity | 0.01 | Heavy materials and high volume production |

| CNC Tapping Machine | Automated tapping operations with precision | 0.05 | Threaded holes in a variety of materials |

Understanding CNC Machine Components and Their Functions

CNC machines have become an integral part of precision machining, and understanding their components is crucial for effective operation. At the heart of these machines lies the controller, which serves as the brain, translating design specifications into precise movements. The controller interfaces with a computer or software, ensuring the machine follows the programmed instructions flawlessly. It plays a pivotal role in executing complex machining tasks, allowing operators to achieve high levels of accuracy in their work processes.

Another essential component is the spindle, which provides the rotational power necessary for cutting tools. The spindle's speed and torque are critical, as they dictate the machining operations' effectiveness and efficiency. Coupled with the spindle are the various cutting tools, each designed for specific materials and applications. These tools are selected based on the machining requirements, influencing factors such as surface finish and dimensional tolerance. Additionally, the bed and frame of the CNC machine provide stability, ensuring precise alignment during operations, which is vital for maintaining the integrity of the final product. Together, these components work harmoniously, enabling a wide range of machining tasks with unparalleled precision.

The Role of Software in Controlling CNC Machining Processes

In the realm of CNC machining, software plays a pivotal role in enhancing precision and efficiency throughout the manufacturing process. Computer Numerical Control (CNC) systems rely on advanced software to convert intricate design specifications into executable machining commands. This not only streamlines the workflow but also reduces the potential for human error. By utilizing sophisticated algorithms, the software ensures that every movement of the machine is calculated, resulting in consistently accurate outputs that meet stringent quality standards.

Moreover, the integration of software in CNC machining enables real-time monitoring and control of the machining operations. Operators can adjust parameters such as speed, feed rate, and tool paths instantly, accommodating any required changes on-the-fly. This flexibility is crucial in precision machining where even the smallest deviation can lead to significant variances in the final product. Additionally, modern CNC software often includes simulation capabilities, allowing manufacturers to visualize machining processes before production begins. This not only aids in identifying potential issues but also optimizes the setup, ensuring that resources are used efficiently and effectively.

Top 10 CNC Machine Types for Precision Machining

Related Posts

-

Exploring the Amazing World of CNC Routers for DIY Enthusiasts

-

10 Essential Tips for Choosing the Right CNC Router for Your Projects

-

Best CNC Router Machine for Beginners and Professionals in 2023

-

Exploring the Future of Manufacturing: How CNC Machines are Revolutionizing Production Techniques

-

The Future of Manufacturing How CNC Machining Parts Revolutionize Production Processes

-

10 Essential Tips for Maximizing Efficiency with Your CNC Mill