- Home

-

-

-

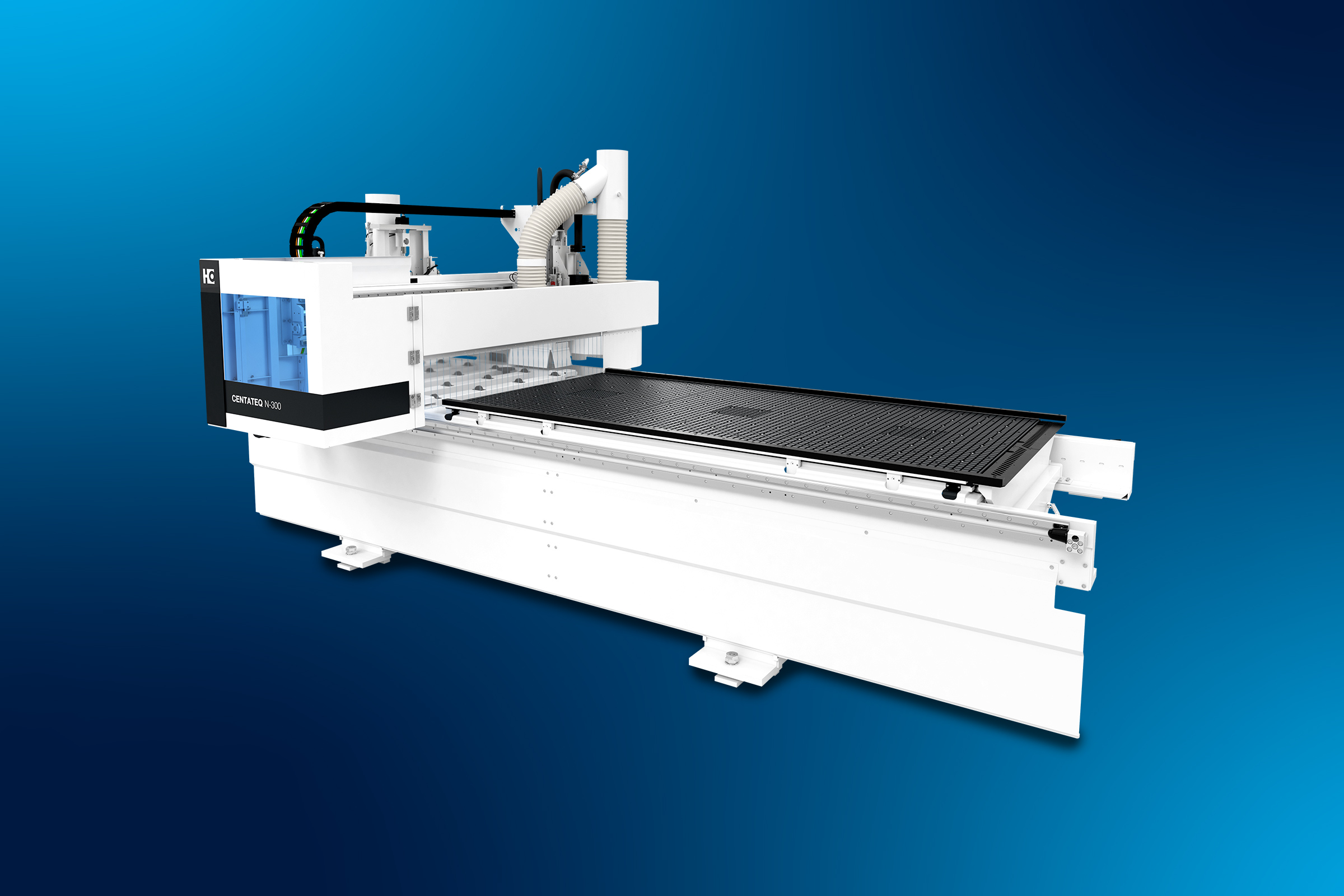

Stiles Enhancement Technologies

-

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

-

-

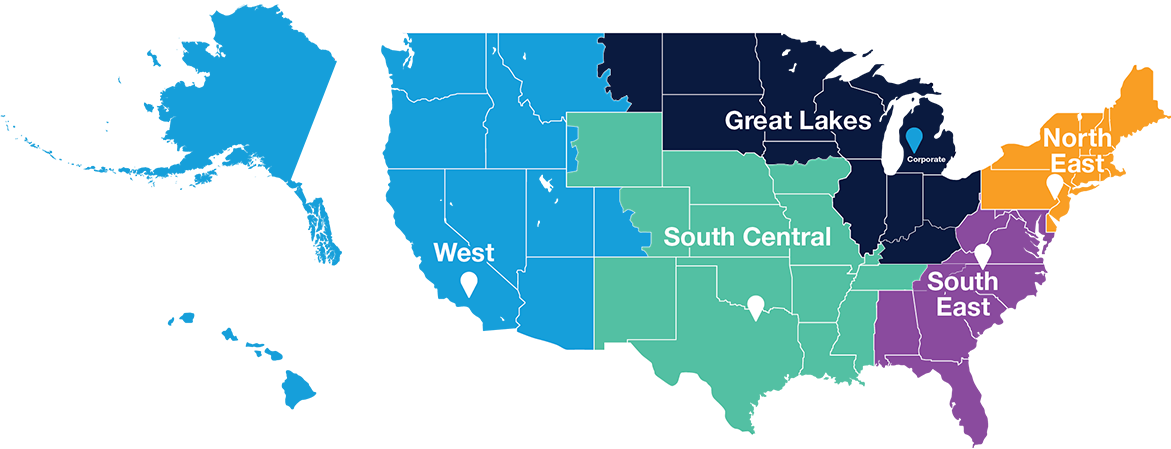

- Stiles Machinery hosts a national network of five regional service centers and nationwide force of over 200 Field Service Representatives put the industry’s best service where it belongs – close to you.

- Routine & Preventative Maintenance

- Technical Support & Diagnostics

- Field Service

- Request an Equipment Manual

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615

Service & Repairs: 616-698-7500

24/7 Parts: 1-800-727-8780

sale@inlandmachineokc.com

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

-

With a customized Stiles University course, we can provide expert training for your team, on-location. Whether it's programming, operation or maintenance, we want to help you train your personnel to meet your production goals efficiently and effectively.

-

Experience the trusted workforce development training and machinery knowledge you rely on from Stiles University, now at your convenience. With technology changing every day and new methods being developed constantly, Stiles University Online has the latest information and training content available at your fingertips.

-

Your solution for workforce development.

616-698-7500

-

-

-

Do you want to produce more efficiently? Processes and flows are key. We optimize these together with you, re-organize them and make sure that you reduce your lead time and save costs. This enables you to implement customized manufacturing and achieve your business goals.

-

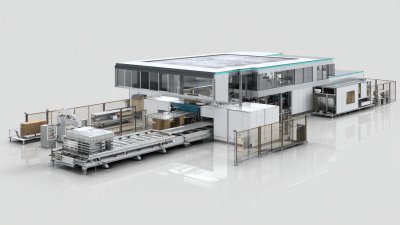

Industrialized construction is evolving. Automation, robotics and advanced technology are raising the level of productivity, efficiency and precision for builders in North America.

-

Stiles Machinery is at the forefront of providing technology and machining for producing high quality mass timber. Automated solutions for your mass timber production can increase your manufacturing quality and productivity.

-

Project management services from Stiles make it easy to streamline your entire project— from concept and consultation to integration and implementation.

-

- Online Store

- News

- Careers

- REQUEST INFO

- Home

-

-

-

Stiles Enhancement Technologies

-

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

-

-

- Stiles Machinery hosts a national network of five regional service centers and nationwide force of over 200 Field Service Representatives put the industry’s best service where it belongs – close to you.

- Routine & Preventative Maintenance

- Technical Support & Diagnostics

- Field Service

- Request an Equipment Manual

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615

Service & Repairs: 616-698-7500

24/7 Parts: 1-800-727-8780

sale@inlandmachineokc.com

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

-

With a customized Stiles University course, we can provide expert training for your team, on-location. Whether it's programming, operation or maintenance, we want to help you train your personnel to meet your production goals efficiently and effectively.

-

Experience the trusted workforce development training and machinery knowledge you rely on from Stiles University, now at your convenience. With technology changing every day and new methods being developed constantly, Stiles University Online has the latest information and training content available at your fingertips.

-

Your solution for workforce development.

616-698-7500

-

-

-

Do you want to produce more efficiently? Processes and flows are key. We optimize these together with you, re-organize them and make sure that you reduce your lead time and save costs. This enables you to implement customized manufacturing and achieve your business goals.

-

Industrialized construction is evolving. Automation, robotics and advanced technology are raising the level of productivity, efficiency and precision for builders in North America.

-

Stiles Machinery is at the forefront of providing technology and machining for producing high quality mass timber. Automated solutions for your mass timber production can increase your manufacturing quality and productivity.

-

Project management services from Stiles make it easy to streamline your entire project— from concept and consultation to integration and implementation.

-

- Online Store

- News

- Careers

- REQUEST INFO

- Home

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

- TECHNICAL SUPPORT

- FIELD SERVICE

- ROUTINE & PREVENTATIVE MAINTENANCE

- REQUEST AN EQUIPMENT MANUAL

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615 Service & Repairs: 616-698-7500 24/7 Parts: 1-800-727-8780

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

- IN-PERSON TRAINING

- CUSTOMIZED COURSES & TRAINING

- STILES UNIVERSITY ONLINE

-

Your solution for workforce development.

- Online Store

- News

- Careers

- FINANCING

- Blog

- REQUEST INFO

- Home

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

- TECHNICAL SUPPORT

- FIELD SERVICE

- ROUTINE & PREVENTATIVE MAINTENANCE

- REQUEST AN EQUIPMENT MANUAL

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615 Service & Repairs: 616-698-7500 24/7 Parts: 1-800-727-8780

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

- IN-PERSON TRAINING

- CUSTOMIZED COURSES & TRAINING

- STILES UNIVERSITY ONLINE

-

Your solution for workforce development.

- Online Store

- News

- Careers

- FINANCING

- Blog

- REQUEST INFO

Top 10 Small CNC Machines for Precision Engineering in 2023

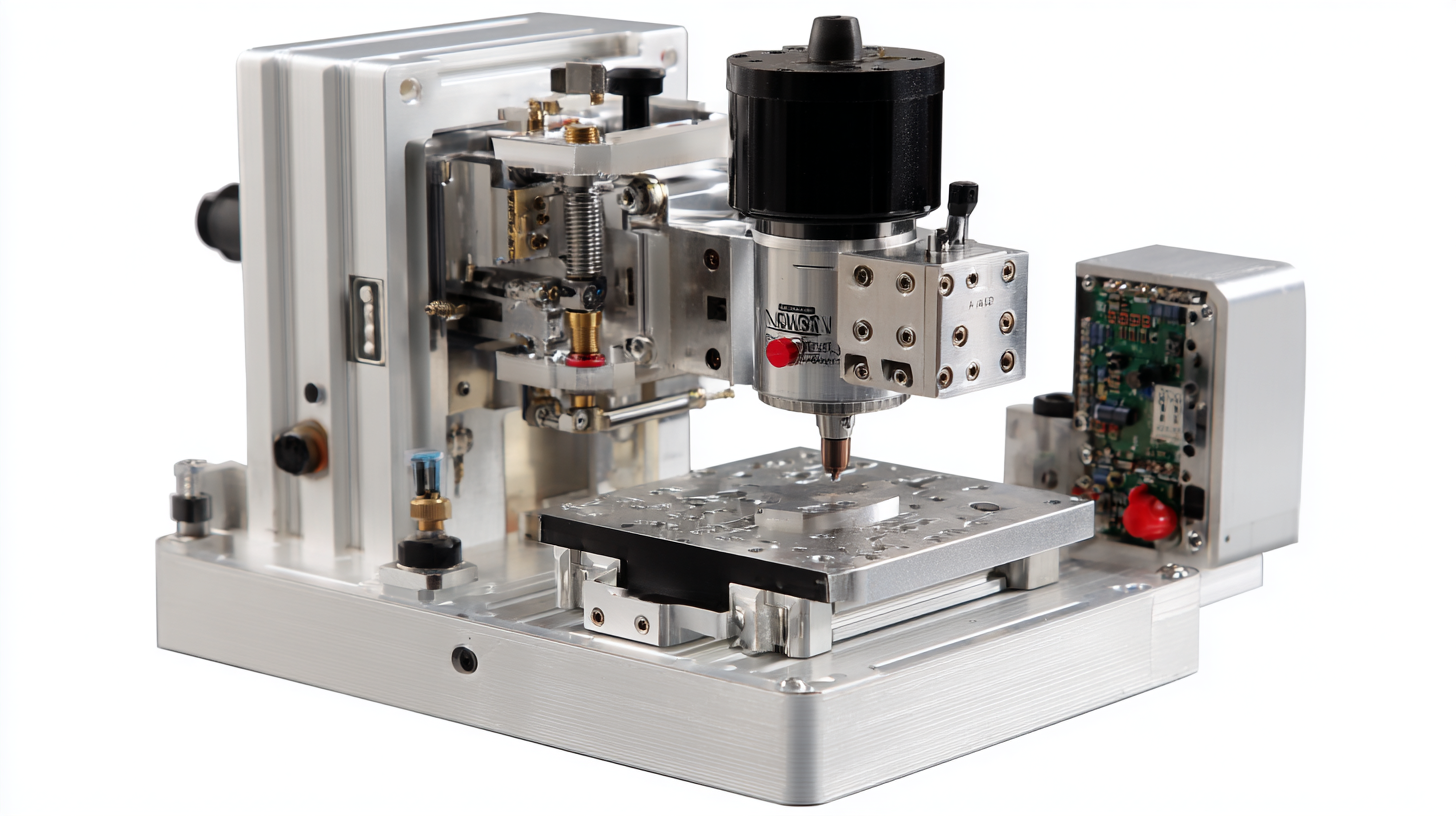

In the realm of precision engineering, small CNC machines have emerged as indispensable tools for both hobbyists and professionals alike. As technology continues to advance, these compact machines demonstrate remarkable capabilities in delivering high-quality output while occupying minimal workspace. Whether you're a small business owner looking to enhance production efficiency or an enthusiast eager to explore the world of CNC machining, understanding the best options available in 2023 is crucial.

This article will delve into the top 10 small CNC machines that stand out in the market this year, highlighting their unique features, specifications, and the advantages they offer. From intricate woodworking projects to intricate metalworking tasks, the versatility of these machines enables users to tackle a wide range of applications with precision and ease. As we explore these remarkable machines, it's clear that investing in a reliable small CNC machine can significantly elevate your capabilities in precision engineering, paving the way for creativity and innovation in your projects.

Emerging Trends in Small CNC Machines for Precision Engineering by 2025

As we look towards 2025, small CNC machines are set to play a pivotal role in advancing precision engineering. The incorporation of artificial intelligence into manufacturing processes is redefining efficiency and productivity. With the global CNC machine tools market expected to grow significantly, driven by the demand for high-precision and multi-axis machining centers, businesses are realizing that investing in small CNC machines can yield substantial benefits. These machines not only enhance precision but also adapt easily to various applications, making them indispensable in modern manufacturing settings.

Tips: When selecting a small CNC machine, assess the specific needs of your project. Consider factors such as the materials you'll be working with and the required precision levels. Additionally, keeping an eye on the latest technological advancements will ensure you invest in machines that will maximize your production capabilities.

Moreover, trends indicate that smaller, more versatile CNC machines are emerging, designed to cater to niche markets and specific precision engineering demands. The focus on compact designs not only saves space but also enhances mobility within the production facility. Investing in such machines may lead to innovative manufacturing solutions that meet the evolving demands of industries by 2025.

Tips: Regularly reviewing the specifications and capabilities of your CNC equipment in line with industry trends can help maintain competitive advantage. Engaging with manufacturers or attending trade shows can provide insights into the latest developments in small CNC machine technologies.

Key Features to Look for in the Best Small CNC Machines

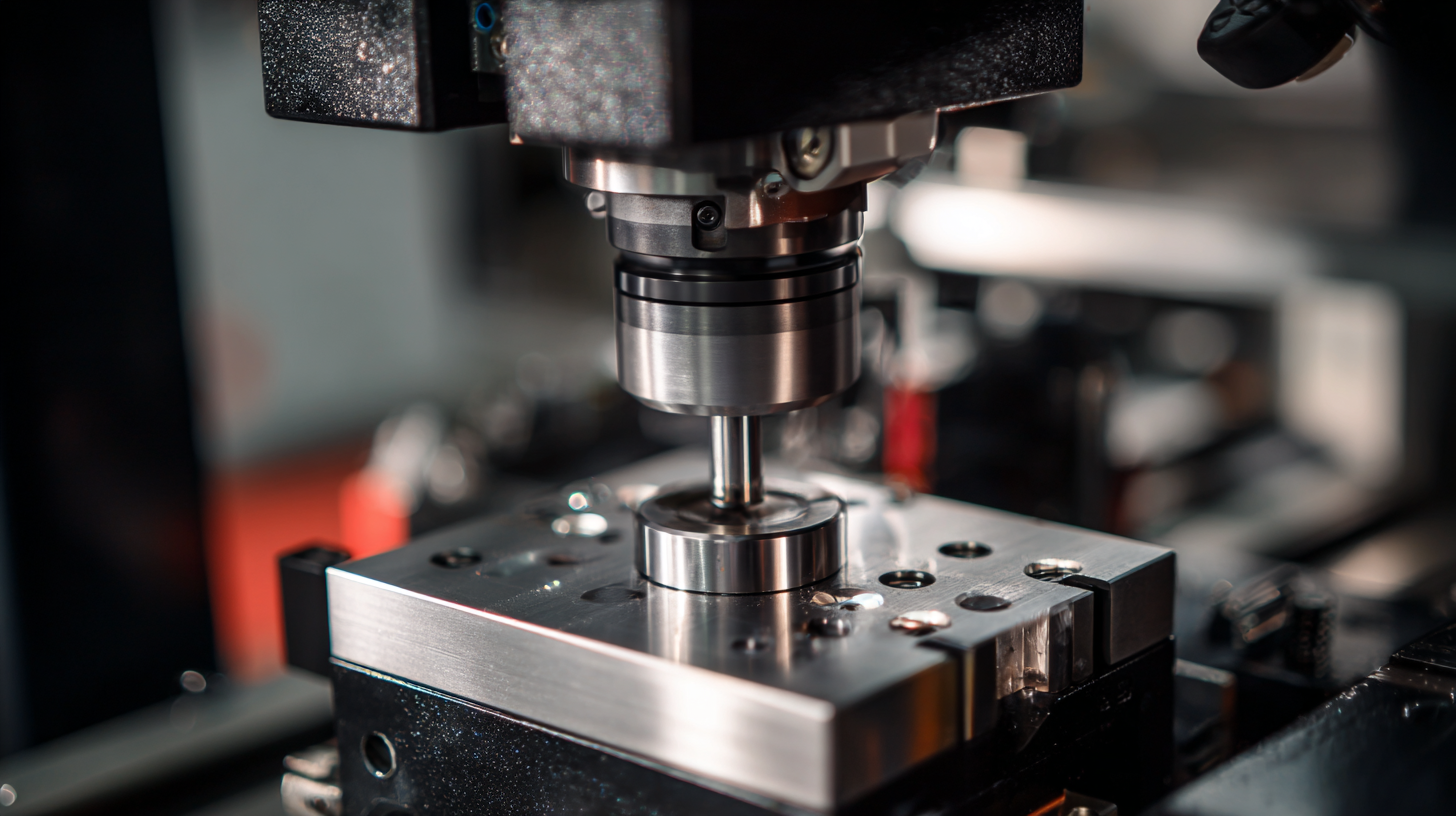

When selecting a small CNC machine for precision engineering in 2023, certain key features should be prioritized to ensure optimal performance and accuracy. First and foremost, consider the machine's rigidity and stability. A robust build reduces vibrations, leading to tighter tolerances and improved surface finishes. Additionally, check the spindle speed and tooling compatibility, as these factors greatly influence machining capabilities. High spindle speeds are essential for precise cutting and can enhance production efficiency.

Tip: Always review the maximum cutting speeds and feed rates specified by manufacturers, as these can give you insight into the machine's overall efficacy for your specific applications.

Another critical feature to examine is the control software. User-friendly software not only simplifies operation but can also increase productivity through advanced programming features. Look for a machine that supports both G-code and conversational programming to cater to different expertise levels. Additionally, ensure that the machine's software is regularly updated to keep pace with advancements in technology.

Tip: Consider machines that offer great customer support and a strong community, as this can be invaluable for troubleshooting and learning best practices.

Comparative Analysis of Top 5 Small CNC Models for 2025

In 2025, the landscape of small CNC machines continues to evolve, with a focus on precision engineering, compact design, and advanced technology. Among the top five models, the **XYZ Mini Pro 3000** stands out for its exceptional accuracy and user-friendly interface, designed specifically for small workshops and hobbyists. Its ability to handle a variety of materials makes it a versatile choice for intricate projects, enabling users to achieve professional-quality results without the need for extensive training.

Another noteworthy contender is the **NanoCut Elite**, which boasts a high-speed spindle and enhanced rigidity, allowing for faster feed rates and reduced vibration. This model excels in detailed engraving and precision cutting, particularly in the aerospace and automotive sectors. The **Precision Micro 750**, with its sophisticated algorithms, offers unparalleled repeatability, making it an ideal choice for production runs where consistency is crucial. Each of these models reflects the trend towards greater sophistication in small CNC machines, catering to the needs of modern precision engineers and makers alike.

Top 10 Small CNC Machines for Precision Engineering in 2023

| Model | Working Area (mm) | Max Speed (mm/min) | Precision (mm) | Price ($) |

|---|---|---|---|---|

| Model A | 300 x 200 x 100 | 5000 | 0.01 | 1200 |

| Model B | 400 x 300 x 150 | 6000 | 0.05 | 1500 |

| Model C | 250 x 200 x 100 | 4000 | 0.02 | 800 |

| Model D | 500 x 400 x 200 | 7000 | 0.03 | 2000 |

| Model E | 300 x 300 x 150 | 5000 | 0.01 | 1350 |

User Experiences and Feedback on 2025's Leading CNC Machines

As the landscape of CNC machine technology continues to evolve, user experiences and feedback become invaluable resources for prospective buyers. In 2025, many leading CNC machines are being praised for their precision, versatility, and user-friendly interfaces. Users have consistently highlighted the benefits of machines with intuitive software that simplifies the programming process, allowing engineers to focus more on design and less on technical troubleshooting. For instance, machines that integrate seamlessly with CAD/CAM software are receiving rave reviews for enhancing workflow efficiency.

When considering a small CNC machine, it’s essential to gather insights from fellow users. Online forums and review websites provide a wealth of knowledge on the reliability and performance of specific models. Tips from experienced operators often emphasize the importance of routine maintenance to preserve accuracy and prolong the machine's lifespan. Investing in a machine that offers excellent customer support can also make a significant difference, as timely assistance with software updates or hardware issues can prevent costly downtimes.

Another common piece of advice among users is to prioritize machines that offer a good balance of automation and manual control. This allows flexibility in operation, accommodating both intricate projects and quicker tasks without extensive setup time. Engaging with the community can help in identifying not only the machines themselves but also best practices that enhance your CNC machining experience.

Future Innovations and Expectations in CNC Technology by 2025

As we look towards 2025, the landscape of CNC technology is set to undergo transformative changes, driven by advancements in automation, AI integration, and machine learning. According to a report by MarketsandMarkets, the global CNC machine market is projected to reach $100 billion by 2025, growing at a CAGR of 6.2% from 2020. This growth is largely fueled by the increasing demand for precision engineering across various industries, including aerospace, automotive, and electronics.

Emerging innovations such as adaptive machining and real-time monitoring systems are enhancing the capabilities of small CNC machines, enabling them to perform complex tasks with unprecedented accuracy. Industry analysts predict that by 2025, nearly 70% of CNC systems will incorporate AI to optimize machining processes, reduce waste, and improve overall efficiency. Additionally, advancements in IoT technology will allow for better connectivity and data sharing between machines, enabling predictive maintenance and minimizing downtime. These innovations not only promise to improve operational productivity but also to facilitate a more sustainable approach to manufacturing in the years to come.

Top 10 Small CNC Machines for Precision Engineering in 2023

Related Posts

-

The Future of Manufacturing How CNC Machining Parts Revolutionize Production Processes

-

Unlocking Precision: How Wood CNC Machines are Revolutionizing the Furniture Industry

-

Revolutionizing Furniture Manufacturing: How Edge Banding Machines Enhance Production Efficiency

-

The Ultimate Guide to Choosing the Best Sanding Machine for Your DIY Projects

-

Unlocking the Potential of Wood CNC Machines for Your Next Creative Project

-

Exploring the Future of Manufacturing: How CNC Machines are Revolutionizing Production Techniques