- Home

-

-

-

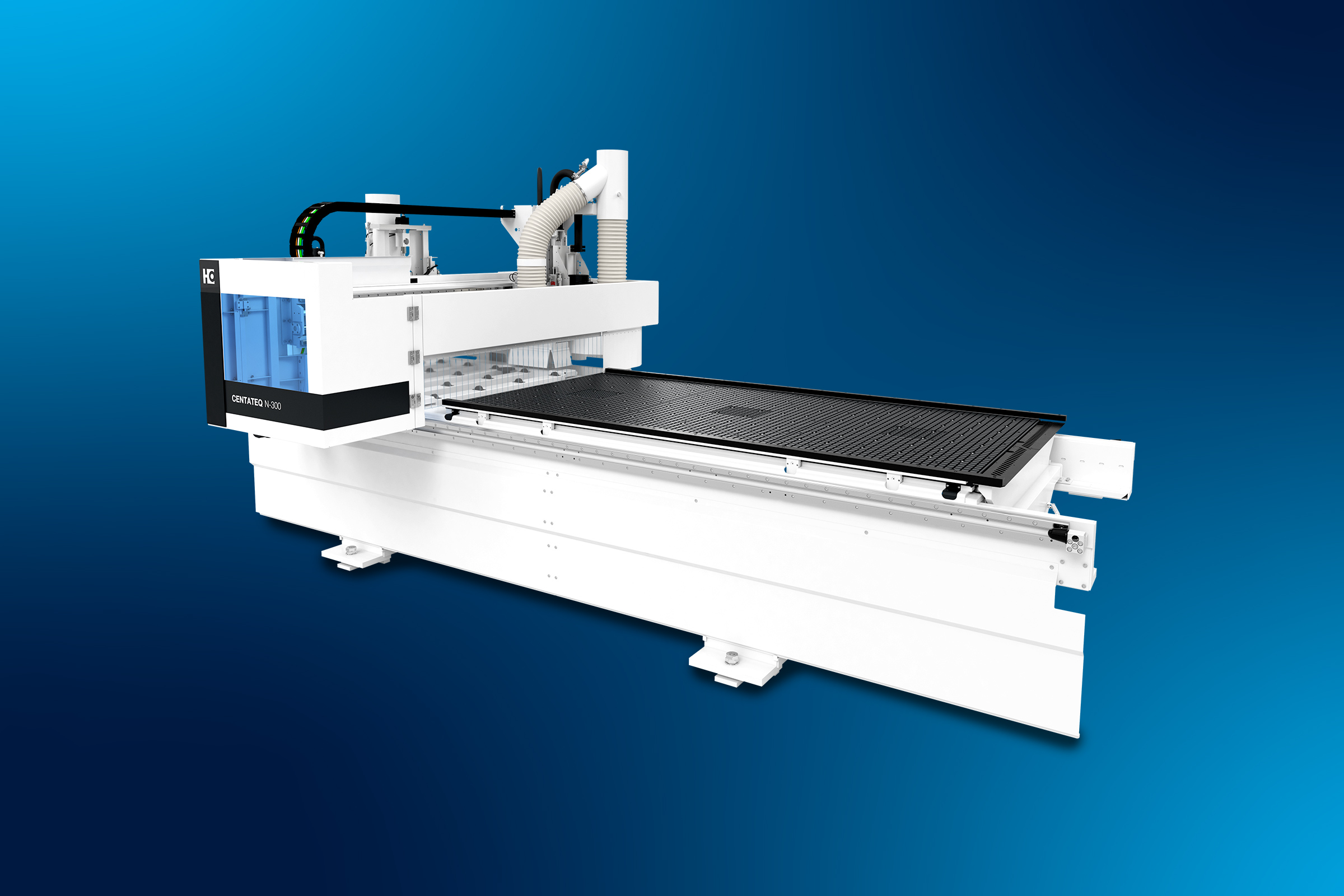

Stiles Enhancement Technologies

-

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

-

-

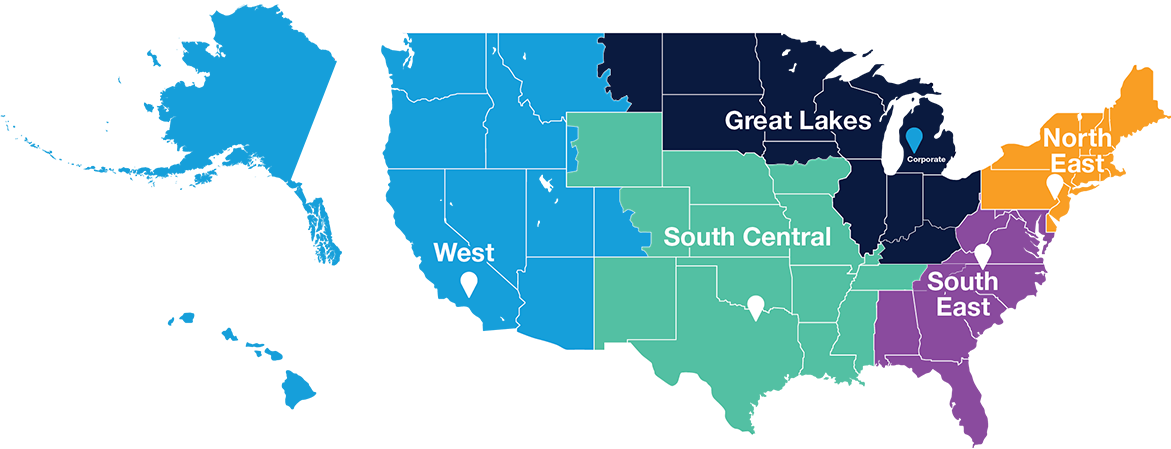

- Stiles Machinery hosts a national network of five regional service centers and nationwide force of over 200 Field Service Representatives put the industry’s best service where it belongs – close to you.

- Routine & Preventative Maintenance

- Technical Support & Diagnostics

- Field Service

- Request an Equipment Manual

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615

Service & Repairs: 616-698-7500

24/7 Parts: 1-800-727-8780

sale@inlandmachineokc.com

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

-

With a customized Stiles University course, we can provide expert training for your team, on-location. Whether it's programming, operation or maintenance, we want to help you train your personnel to meet your production goals efficiently and effectively.

-

Experience the trusted workforce development training and machinery knowledge you rely on from Stiles University, now at your convenience. With technology changing every day and new methods being developed constantly, Stiles University Online has the latest information and training content available at your fingertips.

-

Your solution for workforce development.

616-698-7500

-

-

-

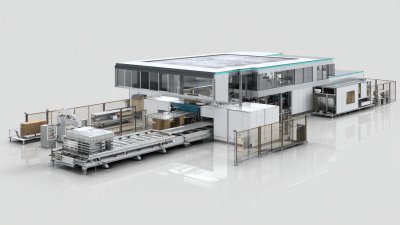

Do you want to produce more efficiently? Processes and flows are key. We optimize these together with you, re-organize them and make sure that you reduce your lead time and save costs. This enables you to implement customized manufacturing and achieve your business goals.

-

Industrialized construction is evolving. Automation, robotics and advanced technology are raising the level of productivity, efficiency and precision for builders in North America.

-

Stiles Machinery is at the forefront of providing technology and machining for producing high quality mass timber. Automated solutions for your mass timber production can increase your manufacturing quality and productivity.

-

Project management services from Stiles make it easy to streamline your entire project— from concept and consultation to integration and implementation.

-

- Online Store

- News

- Careers

- REQUEST INFO

- Home

-

-

-

Stiles Enhancement Technologies

-

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

-

-

- Stiles Machinery hosts a national network of five regional service centers and nationwide force of over 200 Field Service Representatives put the industry’s best service where it belongs – close to you.

- Routine & Preventative Maintenance

- Technical Support & Diagnostics

- Field Service

- Request an Equipment Manual

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615

Service & Repairs: 616-698-7500

24/7 Parts: 1-800-727-8780

sale@inlandmachineokc.com

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

-

With a customized Stiles University course, we can provide expert training for your team, on-location. Whether it's programming, operation or maintenance, we want to help you train your personnel to meet your production goals efficiently and effectively.

-

Experience the trusted workforce development training and machinery knowledge you rely on from Stiles University, now at your convenience. With technology changing every day and new methods being developed constantly, Stiles University Online has the latest information and training content available at your fingertips.

-

Your solution for workforce development.

616-698-7500

-

-

-

Do you want to produce more efficiently? Processes and flows are key. We optimize these together with you, re-organize them and make sure that you reduce your lead time and save costs. This enables you to implement customized manufacturing and achieve your business goals.

-

Industrialized construction is evolving. Automation, robotics and advanced technology are raising the level of productivity, efficiency and precision for builders in North America.

-

Stiles Machinery is at the forefront of providing technology and machining for producing high quality mass timber. Automated solutions for your mass timber production can increase your manufacturing quality and productivity.

-

Project management services from Stiles make it easy to streamline your entire project— from concept and consultation to integration and implementation.

-

- Online Store

- News

- Careers

- REQUEST INFO

- Home

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

- TECHNICAL SUPPORT

- FIELD SERVICE

- ROUTINE & PREVENTATIVE MAINTENANCE

- REQUEST AN EQUIPMENT MANUAL

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615 Service & Repairs: 616-698-7500 24/7 Parts: 1-800-727-8780

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

- IN-PERSON TRAINING

- CUSTOMIZED COURSES & TRAINING

- STILES UNIVERSITY ONLINE

-

Your solution for workforce development.

- Online Store

- News

- Careers

- FINANCING

- Blog

- REQUEST INFO

- Home

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

- TECHNICAL SUPPORT

- FIELD SERVICE

- ROUTINE & PREVENTATIVE MAINTENANCE

- REQUEST AN EQUIPMENT MANUAL

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615 Service & Repairs: 616-698-7500 24/7 Parts: 1-800-727-8780

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

- IN-PERSON TRAINING

- CUSTOMIZED COURSES & TRAINING

- STILES UNIVERSITY ONLINE

-

Your solution for workforce development.

- Online Store

- News

- Careers

- FINANCING

- Blog

- REQUEST INFO

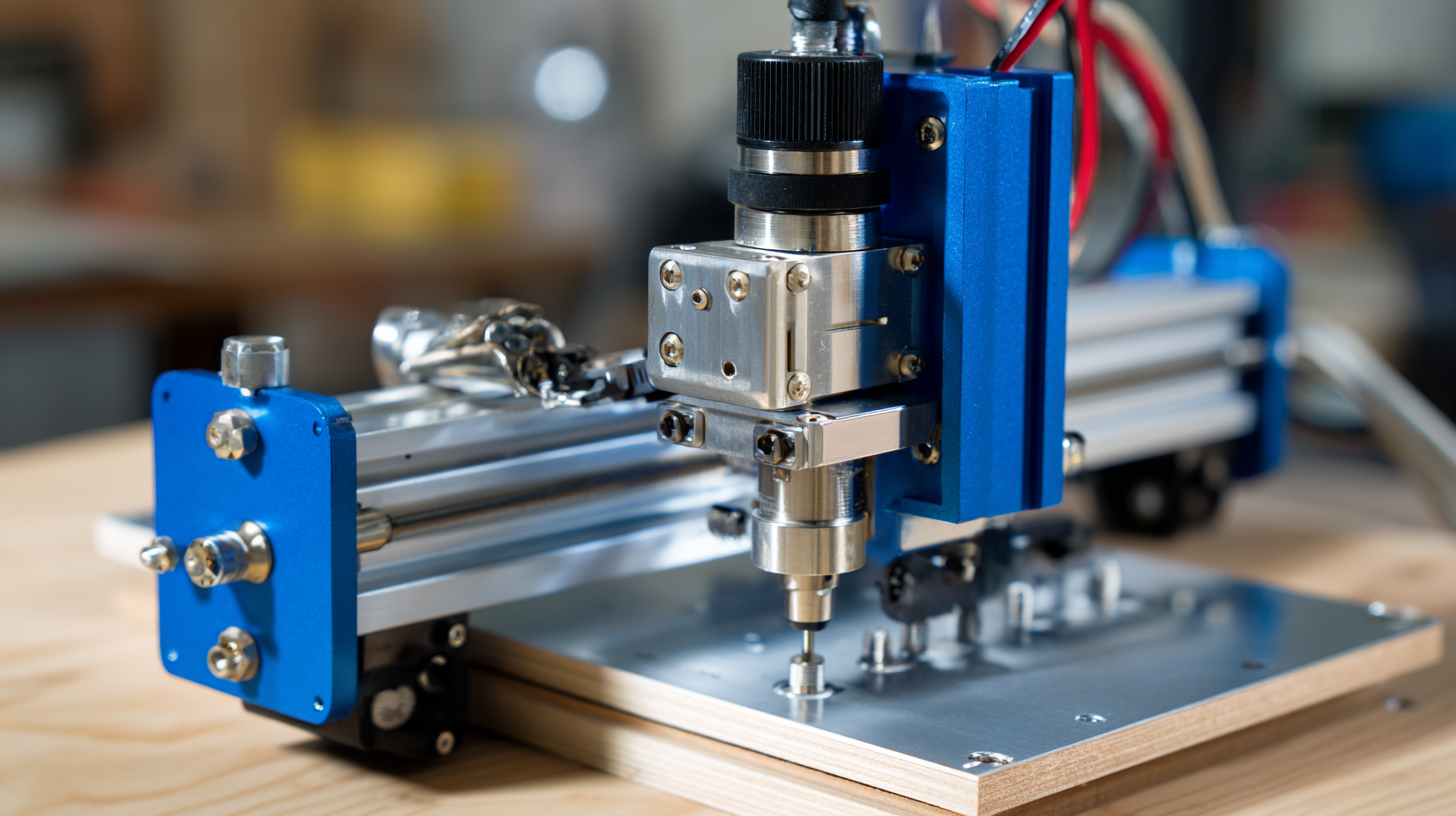

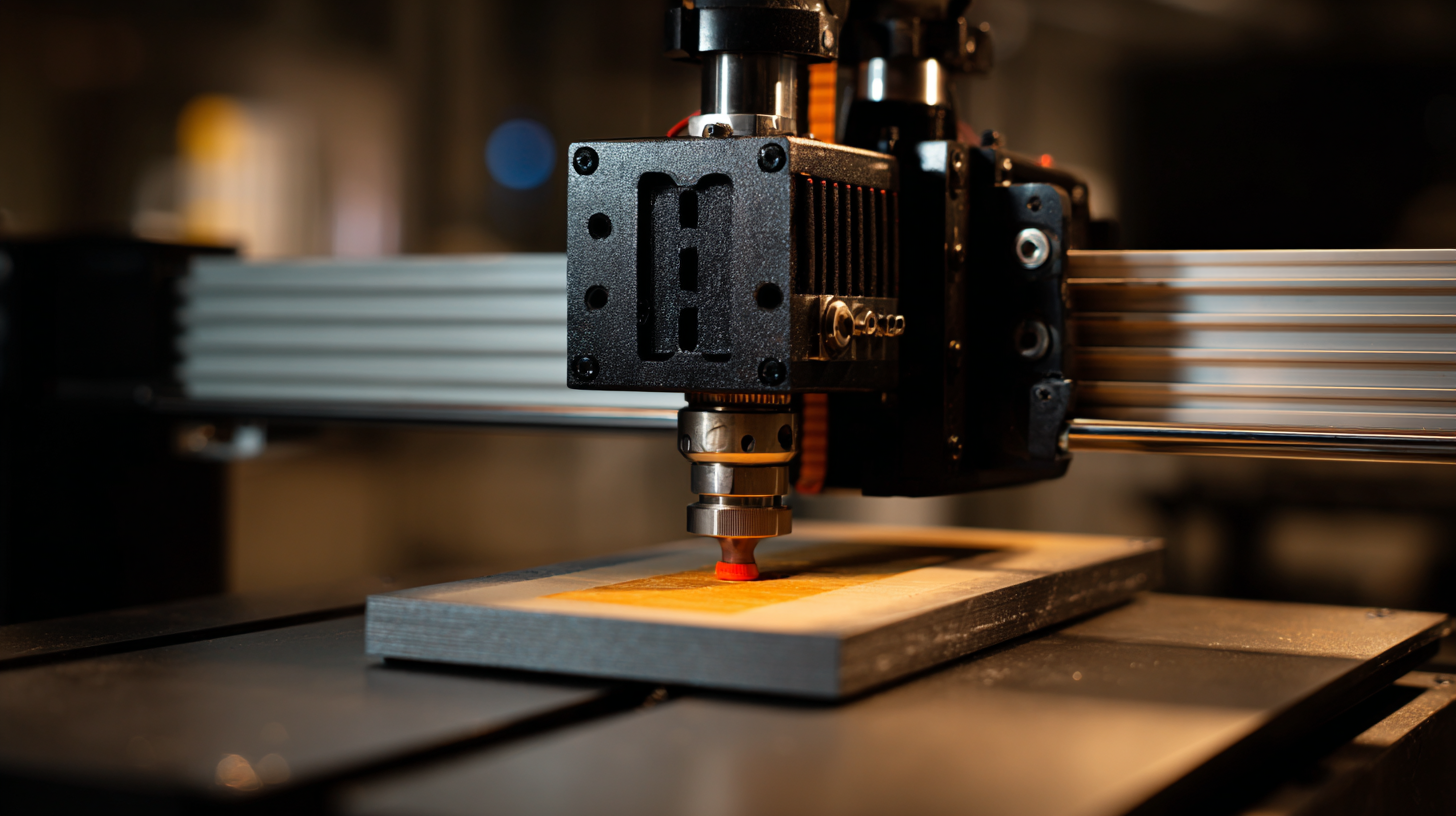

Unlocking Precision: How Small CNC Machines Revolutionize DIY Projects and Prototyping

In the realm of DIY projects and prototyping, the advent of small CNC machines has unlocked a new level of precision and creativity for hobbyists and professionals alike. These compact devices offer the ability to create intricate designs and components that were once only possible with larger, more expensive machinery. As industries continue to embrace automation and innovation, the small CNC machine has emerged as a game changer, democratizing access to advanced manufacturing techniques.

Whether for crafting personalized items, developing prototypes, or exploring artistic endeavors, these machines provide an unparalleled opportunity to bring ideas to life with accuracy that can be difficult to achieve by hand. By harnessing the power of small CNC machines, creators can push the boundaries of their projects, transforming the way they design, build, and innovate.

The Rise of Small CNC Machines: A Game Changer for DIY Enthusiasts

The rise of small CNC machines has marked a transformative shift for DIY enthusiasts, enabling an unprecedented level of precision and creativity in personal projects and prototyping. According to a recent report by MarketResearchFuture, the global CNC machine market is projected to reach over $100 billion by 2025, with a significant portion attributed to the growing popularity of compact, user-friendly models designed for hobbyists. This surge in demand reflects not only the accessibility of technology but also its ability to empower individuals to take their creative ideas from concept to reality with professional-grade accuracy.

Small CNC machines allow users to fabricate intricate designs and components that were once exclusive to industrial settings. A study by Technavio highlights that the adoption of these machines among small-scale manufacturers and DIYers is rising, with a potential growth rate of 6% annually. This expansion is fueled by innovations in software and hardware that reduce the learning curve, making it easier for newcomers to engage in advanced projects. As DIY enthusiasts leverage these machines for everything from custom furniture to detailed art pieces, they are redefining the boundaries of creativity and craftsmanship in the modern maker movement.

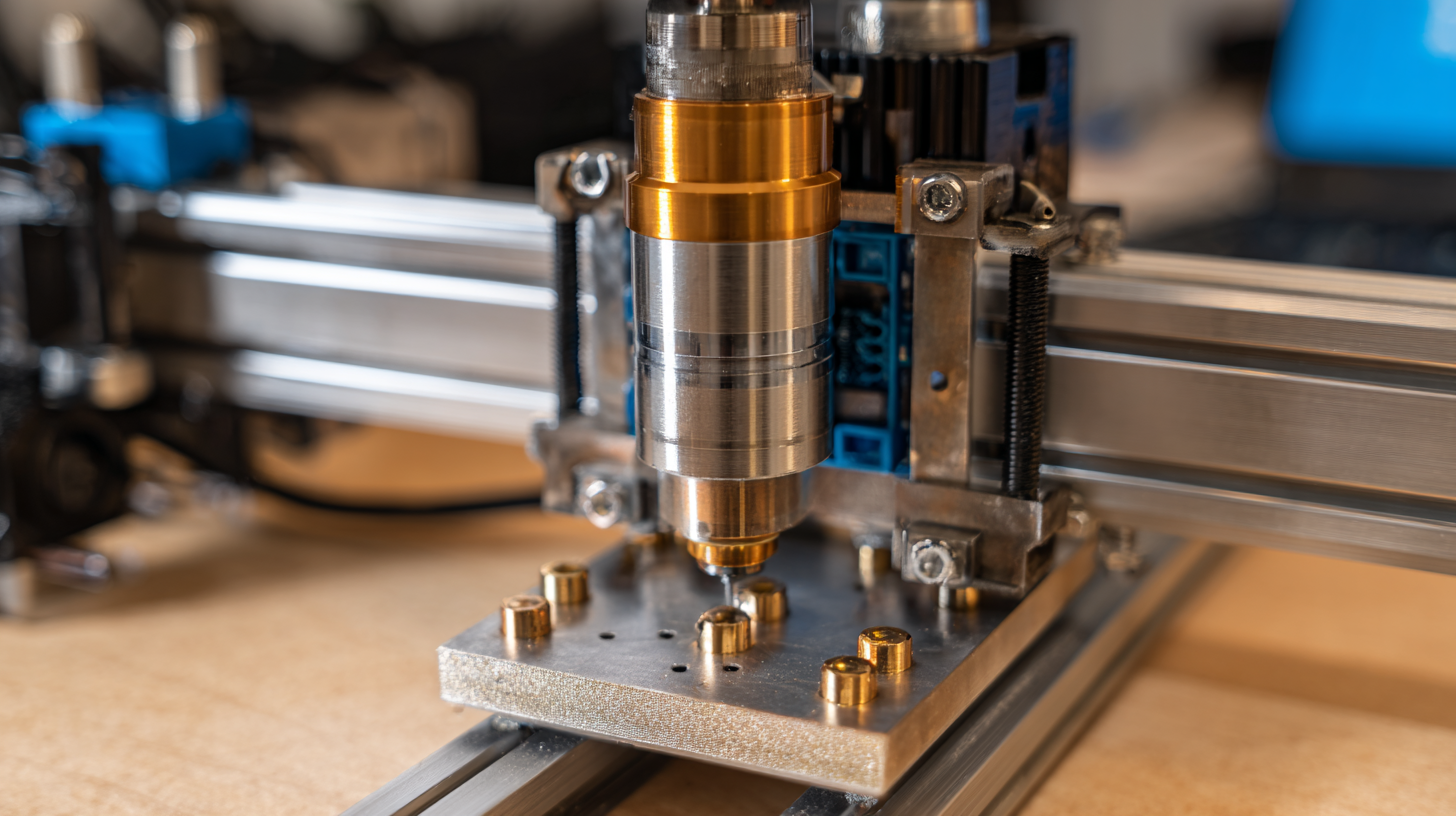

Precision Engineering: The Key Advantages of CNC Technology in Prototyping

The integration of CNC technology into precision engineering has brought transformative advantages to prototyping processes. By enabling incredibly fine tolerances and precision cuts, CNC machines allow designers and engineers to create intricate prototypes that were previously unattainable through traditional manufacturing methods. This enhanced level of accuracy is essential in industries like medical device manufacturing, where even the smallest deviation can impact functionality and safety. With the ability to automate complex processes, CNC machines also reduce the time needed for prototype development, accelerating the overall time to market.

Furthermore, the advent of modern CNC machining services has empowered small businesses and DIY enthusiasts to experiment with advanced manufacturing techniques. The accessibility of these small-scale CNC machines democratizes precision engineering, allowing innovators to bring their ideas to life in a cost-effective manner. This shift not only enhances productivity but also encourages creativity as individuals can rapidly iterate designs and test concepts without the burden of significant financial investments. The result is a vibrant ecosystem of innovation that thrives on the ability to produce high-quality prototypes efficiently.

Cost-Effectiveness: How Small CNC Machines Lower Barriers for Makers and Inventors

The advent of small CNC machines has significantly diminished the financial barriers traditionally associated with manufacturing and prototyping. Maker enthusiasts and inventors, who once found themselves hindered by the high costs of industrial machinery, can now access precise machining tools at a fraction of the price. This cost-effectiveness means that even hobbyists with limited budgets can create intricate designs, allowing for greater experimentation and innovation.

Moreover, the reduced size of these machines not only makes them affordable but also makes them more accessible in home workshops. This democratization of advanced manufacturing technology empowers a broader range of individuals to bring their ideas to life. The precision offered by small CNC machines ensures that these DIY projects yield professional-quality results, transforming the way makers approach prototyping and product development. Ultimately, this shift is fostering a vibrant community of creators eager to explore the possibilities of their inventions without the burden of significant financial investment.

Market Growth: The Expanding Small CNC Machine Industry and Its Impact on Innovation

The small CNC machine industry is witnessing remarkable growth, driven by rising demand across various sectors. By 2024, the metal manufacturing market is projected to reach a value of $82.09 billion, continuing to expand towards an estimated $100.818 billion by 2033, with a compound annual growth rate (CAGR) of 3.1%. This growth is indicative of a broader trend where precision-engineered tools are becoming essential in DIY projects and prototyping. The integration of CNC technology enables hobbyists and small manufacturers to produce high-quality components with unparalleled accuracy.

In the woodworking sector, the market size is anticipated to grow significantly, from $40.07 billion in 2025 to $75.94 billion by 2033, marking a robust growth rate of 6.74%. This expansion is closely linked to advancements in CNC machine technology, allowing for more precise fabrication of wooden products. Additionally, the engraving machine market is expected to reach $6.2 billion by 2032, underlining the growing popularity of automated tools in arts and crafts, further showcasing the transformative impact of small CNC machines on optimizing production processes.

Market Growth of Small CNC Machines (2020-2025)

The graph above illustrates the projected market growth of small CNC machines from 2020 to 2025, showcasing a significant increase in market size driven by the rise in DIY projects and prototyping needs.

Real-World Applications: Successful DIY Projects Enabled by Small CNC Technology

Small CNC machines are transforming the DIY and prototyping landscape, enabling hobbyists and professionals alike to bring their ideas to life with unprecedented precision. According to recent industry reports, the global small CNC machine market is projected to grow significantly, driven by increased interest in personalized manufacturing and rapid prototyping. For instance, a research study by MarketsandMarkets highlights that the CNC machining market is anticipated to reach USD 100 billion by 2025, with small-scale applications leading the charge due to their accessibility and affordability.

Real-world applications of small CNC technology can be seen in various DIY projects, from intricate woodworking to custom metal parts. Many enthusiasts have successfully utilized small CNC machines to create bespoke furniture, intricate signage, and even detailed model prototypes. Data from the American Institute of Architects indicates a growing trend in DIY renovations, with 69% of homeowners currently engaged in personal projects that could benefit from CNC technology. This not only enhances creativity but also significantly reduces time and labor costs, enabling creators to execute complex designs that were once only feasible in industrial settings.

With continuous advancements in CNC software and hardware, hobbyists are now empowered to achieve results that mimic professional-grade work, further fueling the DIY movement. The ability to quickly iterate designs using small CNC machines is particularly valuable in prototyping, allowing for rapid testing and modifications. As the gap between professional and amateur fabrication narrows, the landscape of DIY projects is poised for a revolution driven by precision and accessibility.

Related Posts

-

The Ultimate Guide to Choosing the Best Sanding Machine for Your DIY Projects

-

Exploring the Future of Manufacturing: How CNC Machines are Revolutionizing Production Techniques

-

Revolutionizing Furniture Manufacturing: How Edge Banding Machines Enhance Production Efficiency

-

Exploring the Amazing World of CNC Routers for DIY Enthusiasts

-

Unlocking the Potential of Wood CNC Machines for Your Next Creative Project

-

The Future of Manufacturing How CNC Machining Parts Revolutionize Production Processes