- Home

-

-

-

Stiles Enhancement Technologies

-

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

-

-

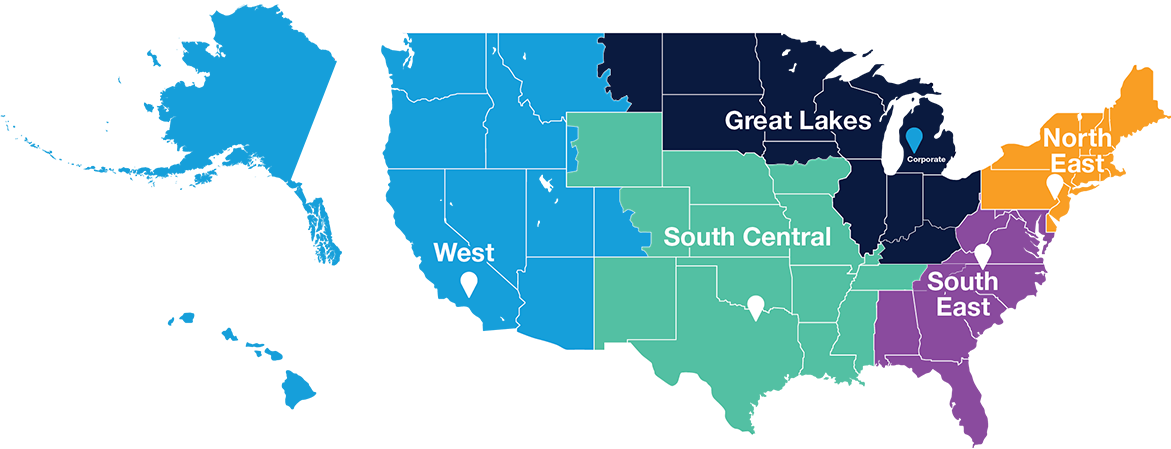

- Stiles Machinery hosts a national network of five regional service centers and nationwide force of over 200 Field Service Representatives put the industry’s best service where it belongs – close to you.

- Routine & Preventative Maintenance

- Technical Support & Diagnostics

- Field Service

- Request an Equipment Manual

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615

Service & Repairs: 616-698-7500

24/7 Parts: 1-800-727-8780

sale@inlandmachineokc.com

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

-

With a customized Stiles University course, we can provide expert training for your team, on-location. Whether it's programming, operation or maintenance, we want to help you train your personnel to meet your production goals efficiently and effectively.

-

Experience the trusted workforce development training and machinery knowledge you rely on from Stiles University, now at your convenience. With technology changing every day and new methods being developed constantly, Stiles University Online has the latest information and training content available at your fingertips.

-

Your solution for workforce development.

616-698-7500

-

-

-

Do you want to produce more efficiently? Processes and flows are key. We optimize these together with you, re-organize them and make sure that you reduce your lead time and save costs. This enables you to implement customized manufacturing and achieve your business goals.

-

Industrialized construction is evolving. Automation, robotics and advanced technology are raising the level of productivity, efficiency and precision for builders in North America.

-

Stiles Machinery is at the forefront of providing technology and machining for producing high quality mass timber. Automated solutions for your mass timber production can increase your manufacturing quality and productivity.

-

Project management services from Stiles make it easy to streamline your entire project— from concept and consultation to integration and implementation.

-

- Online Store

- News

- Careers

- REQUEST INFO

- Home

-

-

-

Stiles Enhancement Technologies

-

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

-

-

- Stiles Machinery hosts a national network of five regional service centers and nationwide force of over 200 Field Service Representatives put the industry’s best service where it belongs – close to you.

- Routine & Preventative Maintenance

- Technical Support & Diagnostics

- Field Service

- Request an Equipment Manual

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615

Service & Repairs: 616-698-7500

24/7 Parts: 1-800-727-8780

sale@inlandmachineokc.com

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

-

With a customized Stiles University course, we can provide expert training for your team, on-location. Whether it's programming, operation or maintenance, we want to help you train your personnel to meet your production goals efficiently and effectively.

-

Experience the trusted workforce development training and machinery knowledge you rely on from Stiles University, now at your convenience. With technology changing every day and new methods being developed constantly, Stiles University Online has the latest information and training content available at your fingertips.

-

Your solution for workforce development.

616-698-7500

-

-

-

Do you want to produce more efficiently? Processes and flows are key. We optimize these together with you, re-organize them and make sure that you reduce your lead time and save costs. This enables you to implement customized manufacturing and achieve your business goals.

-

Industrialized construction is evolving. Automation, robotics and advanced technology are raising the level of productivity, efficiency and precision for builders in North America.

-

Stiles Machinery is at the forefront of providing technology and machining for producing high quality mass timber. Automated solutions for your mass timber production can increase your manufacturing quality and productivity.

-

Project management services from Stiles make it easy to streamline your entire project— from concept and consultation to integration and implementation.

-

- Online Store

- News

- Careers

- REQUEST INFO

- Home

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

- TECHNICAL SUPPORT

- FIELD SERVICE

- ROUTINE & PREVENTATIVE MAINTENANCE

- REQUEST AN EQUIPMENT MANUAL

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615 Service & Repairs: 616-698-7500 24/7 Parts: 1-800-727-8780

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

- IN-PERSON TRAINING

- CUSTOMIZED COURSES & TRAINING

- STILES UNIVERSITY ONLINE

-

Your solution for workforce development.

- Online Store

- News

- Careers

- FINANCING

- Blog

- REQUEST INFO

- Home

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

- TECHNICAL SUPPORT

- FIELD SERVICE

- ROUTINE & PREVENTATIVE MAINTENANCE

- REQUEST AN EQUIPMENT MANUAL

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615 Service & Repairs: 616-698-7500 24/7 Parts: 1-800-727-8780

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

- IN-PERSON TRAINING

- CUSTOMIZED COURSES & TRAINING

- STILES UNIVERSITY ONLINE

-

Your solution for workforce development.

- Online Store

- News

- Careers

- FINANCING

- Blog

- REQUEST INFO

Top 10 Tips for Using a Sliding Table Saw Efficiently and Safely

In the world of woodworking, efficiency and safety are paramount, especially when working with complex machinery like the sliding table saw. Renowned woodworking expert John Smith once said, "A sliding table saw is not just a tool; it's an extension of a craftsman's skill, allowing for precision and creativity." This statement perfectly encapsulates the importance of mastering this powerful equipment to achieve the best results in projects ranging from cabinetry to intricate furniture design.

As we delve into the essential tips for using a sliding table saw efficiently and safely, it becomes clear that understanding the machine's capabilities and limitations is crucial. Proper setup, meticulous adjustments, and strict adherence to safety protocols can significantly elevate one's woodworking experience. By following best practices, woodworkers can harness the full potential of the sliding table saw, ensuring accurate cuts and a safer workshop environment.

In this article, we aim to provide you with the top ten tips that encapsulate both efficiency and safety when operating a sliding table saw. Whether you are a seasoned professional or an enthusiastic hobbyist, these insights will help you navigate the intricacies of this indispensable tool, ensuring a rewarding woodworking journey.

Understanding the Sliding Table Saw: Key Features and Specifications

A sliding table saw is an invaluable tool in woodworking, combining precision and efficiency in cutting large pieces of material. Understanding its key features and specifications can significantly enhance its usage in any workshop. One of the most important specifications is the sliding table's length, which typically ranges between 2 and 3 meters. This extended platform enables users to work with larger sheets of material, reducing the need for repetitive handling and potential injuries associated with lifting heavy objects. According to industry reports, saws with longer sliding tables can improve cutting accuracy by up to 30%, thus ensuring cleaner cuts and reducing waste.

Another critical feature to consider is the fence system. A robust and easily adjustable fence is essential for achieving consistent and accurate cuts. Many modern sliding table saws come equipped with a scoring blade, which allows for cleaner cuts in materials such as melamine or laminate, where chipping can be a significant issue. Research indicates that utilizing a scoring blade can minimize chipping by over 50%, making it a necessary feature for professionals in cabinetry and furniture making. The saw's dust extraction capability is also worth noting; efficient dust collection systems can enhance visibility and worksite cleanliness, contributing to a safer working environment. Overall, understanding these key features will not only facilitate the proper use of a sliding table saw but also enhance safety and efficiency in various woodworking applications.

Essential Safety Gear for Operating a Sliding Table Saw Effectively

When operating a sliding table saw, ensuring safety should be your top priority. One of the most crucial components of safety while working with power tools is wearing the appropriate protective gear. A well-fitted pair of safety goggles is essential to protect your eyes from flying debris and wood chips. Additionally, earmuffs or earplugs should be used to safeguard your hearing from the loud noise produced by the saw, which can lead to long-term hearing loss if left unprotected.

Moreover, wearing a dust mask or respirator is vital, especially when cutting materials that generate fine dust or harmful particles. This not only protects your lungs but also keeps your workspace cleaner. Sturdy work gloves are equally important as they provide grip and protect your hands from accidental cuts and abrasions. Finally, ensure your clothing fits well; loose clothing can easily get caught in the saw. By equipping yourself with these essential safety gear items, you can significantly reduce the risk of accidents and injuries, allowing you to focus on achieving precise and efficient cuts.

Top 10 Tips for Using a Sliding Table Saw Efficiently and Safely

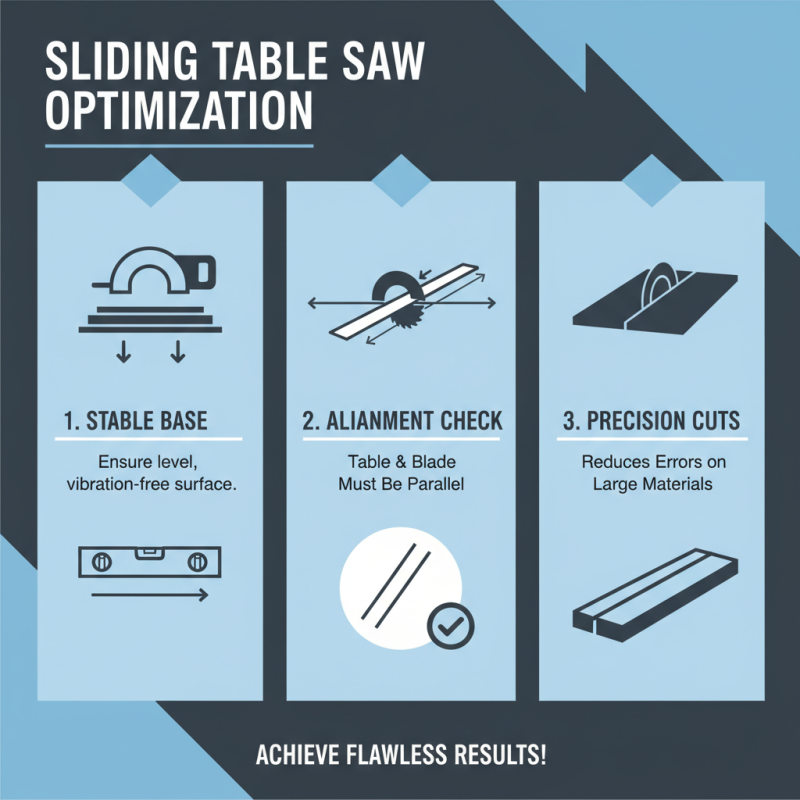

Optimal Setup and Calibration Techniques for Precision Cutting

To achieve optimal performance with a sliding table saw, precise setup and calibration are essential. Start by ensuring the saw is placed on a stable, level surface that can accommodate its weight and size. Leveling the saw eliminates any unwanted vibration during operation, which can lead to inaccuracies in cuts. Use a reliable straightedge to check alignment, ensuring the table and the blade are parallel. This critical step helps maintain the integrity of your cuts, especially when working with larger sheets of material.

Once positioned, calibrate the blade height and angle carefully. Set the blade height to slightly exceed the thickness of the material being cut to minimize the risk of kickback and ensure a clean cut. Additionally, verify the angle of the blade with an accurate protractor or digital angle gauge, especially if making bevel cuts. Regularly checking these settings can drastically improve your cutting accuracy and overall safety. Lastly, be attentive to the sliding mechanism; ensure it moves smoothly and is free of debris. This not only enhances your cutting efficiency but also ensures a safer working environment.

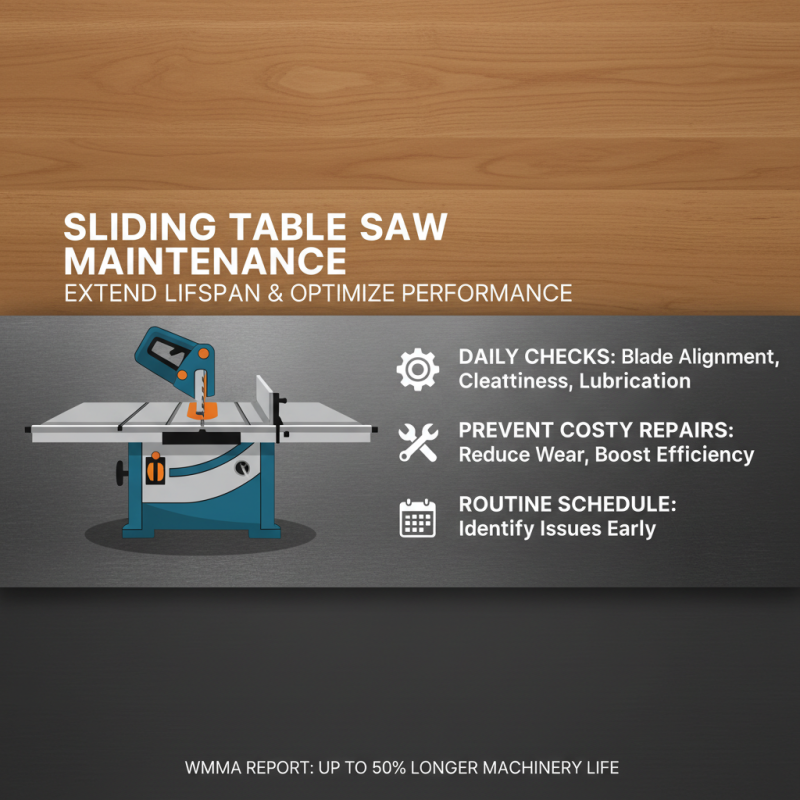

Maintaining Your Sliding Table Saw: Best Practices for Longevity

Maintaining your sliding table saw is crucial for ensuring its longevity and optimal performance. According to a report by the Woodworking Machinery Manufacturers of America, regular maintenance can extend the lifespan of machinery by up to 50%. This includes daily checks for blade alignment, cleanliness, and lubrication of moving parts. A clean machine not only operates more efficiently but also reduces wear on components, preventing costly repairs. Implementing a routine maintenance schedule can help identify potential issues before they escalate, allowing for timely interventions that preserve the saw’s functionality.

Another essential aspect of maintenance is the care of the saw blade. A well-maintained blade can improve cut quality and reduce strain on the motor, ultimately enhancing the overall efficiency of the sliding table saw. Manufacturers recommend sharpening blades after every 10-15 boards, depending on the type of material being cut. Additionally, using a suitable blade for the material at hand minimizes stress on the machine, contributing to its longevity. By taking these maintenance steps seriously, woodworkers can promote a safer working environment and reduce the likelihood of accidents caused by equipment malfunction.

Advanced Cutting Techniques: Maximizing Efficiency with Your Saw

When utilizing a sliding table saw, mastering advanced cutting techniques can significantly enhance both precision and efficiency in your woodworking projects. One essential technique is the use of the sliding table to perform crosscuts. Instead of relying solely on the miter gauge, which can often lead to inaccuracies, the sliding table allows for larger panels to be cut while maintaining a straight, consistent line. To maximize efficiency, ensure that the workpiece is securely clamped to the table, which minimizes movement and helps achieve flawless cuts.

Another effective approach involves making repetitive cuts using a stop block. By attaching a stop block to the sliding table, you can quickly and easily produce multiple pieces of the same size without the need for constant measuring. This not only speeds up the process but also reduces the risk of errors that can occur with manual measuring. Additionally, familiarize yourself with advanced blade setups, such as using multiple blades for different cuts. For example, a combination blade can be great for crosscutting, while a dedicated ripping blade can significantly improve the ease and speed of long cuts. Properly adjusting the blade height and angle settings ensures more versatile cutting capabilities, ultimately leading to a more efficient workflow.

Top 10 Tips for Using a Sliding Table Saw Efficiently and Safely

| Tip No. | Tip | Description | Safety Note |

|---|---|---|---|

| 1 | Use Proper Eye Protection | Always wear safety glasses to protect against particles. | Eye injuries can occur from flying debris. |

| 2 | Adjust Blade Height | Set the blade height to just above the thickness of the material being cut. | Too high can risk kickback. |

| 3 | Use a Push Stick | Utilize a push stick or block for feeding narrow pieces. | Keeps fingers away from the blade. |

| 4 | Maintain Computer Precision | Regularly calibrate your saw for accurate cuts. | Improper calibration can lead to mistakes and waste. |

| 5 | Work with a Clean Surface | Keep the table saw clear of debris for safe operation. | Clutter can lead to accidents. |

| 6 | Select the Right Blade for the Material | Choose blades based on the type of material being cut. | Using the wrong blade can lead to poor cuts and safety hazards. |

| 7 | Secure Your Workpiece | Always secure your material to prevent movement while cutting. | Unstable workpieces can cause kickbacks. |

| 8 | Use Saw Guards | Always use blade guards to reduce risk of exposure. | Guards enhance safety significantly. |

| 9 | Plan Cuts Before Starting | Measure and mark your cuts to ensure precision. | Rushed cuts lead to mistakes. |

| 10 | Disconnect When Not in Use | Always unplug the saw when changing blades or making adjustments. | Prevents accidental startup. |

Related Posts

-

2025 Guide: How to Choose the Best CNC Machining Parts for Your Projects

-

Top 5 CNC Router Kits for Ultimate Precision and DIY Projects in 2023

-

Unlocking Precision: How Small CNC Machines Revolutionize DIY Projects and Prototyping

-

How to Choose the Best CNC Router Machine for Your Projects

-

Top 10 Small CNC Machines for Precision Engineering in 2023

-

2025 Top 5 Rotary Screw Air Compressors for Enhanced Performance