- Home

-

-

-

Stiles Enhancement Technologies

-

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

-

-

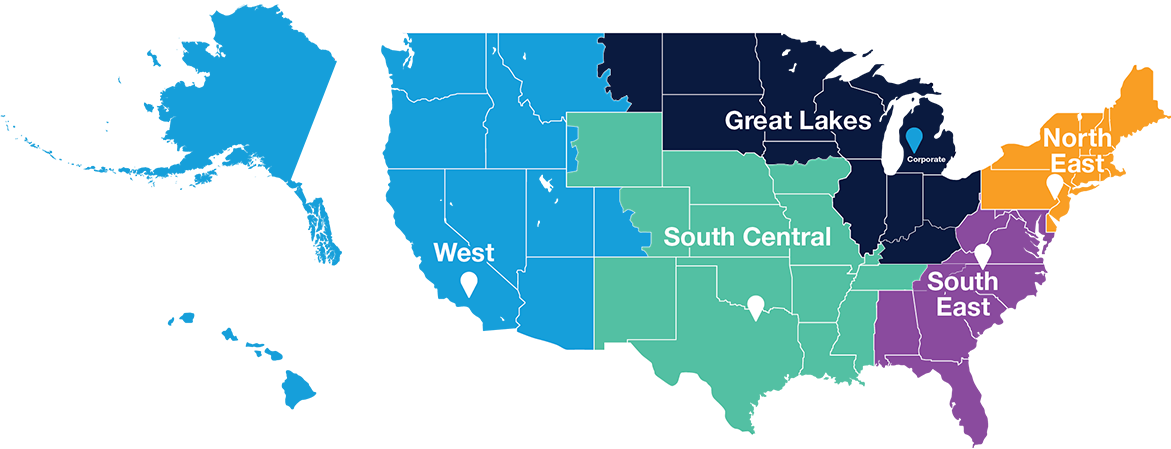

- Stiles Machinery hosts a national network of five regional service centers and nationwide force of over 200 Field Service Representatives put the industry’s best service where it belongs – close to you.

- Routine & Preventative Maintenance

- Technical Support & Diagnostics

- Field Service

- Request an Equipment Manual

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615

Service & Repairs: 616-698-7500

24/7 Parts: 1-800-727-8780

sale@inlandmachineokc.com

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

-

With a customized Stiles University course, we can provide expert training for your team, on-location. Whether it's programming, operation or maintenance, we want to help you train your personnel to meet your production goals efficiently and effectively.

-

Experience the trusted workforce development training and machinery knowledge you rely on from Stiles University, now at your convenience. With technology changing every day and new methods being developed constantly, Stiles University Online has the latest information and training content available at your fingertips.

-

Your solution for workforce development.

616-698-7500

-

-

-

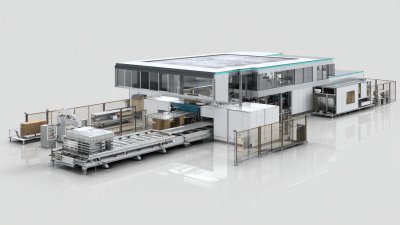

Do you want to produce more efficiently? Processes and flows are key. We optimize these together with you, re-organize them and make sure that you reduce your lead time and save costs. This enables you to implement customized manufacturing and achieve your business goals.

-

Industrialized construction is evolving. Automation, robotics and advanced technology are raising the level of productivity, efficiency and precision for builders in North America.

-

Stiles Machinery is at the forefront of providing technology and machining for producing high quality mass timber. Automated solutions for your mass timber production can increase your manufacturing quality and productivity.

-

Project management services from Stiles make it easy to streamline your entire project— from concept and consultation to integration and implementation.

-

- Online Store

- News

- Careers

- REQUEST INFO

- Home

-

-

-

Stiles Enhancement Technologies

-

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

-

-

- Stiles Machinery hosts a national network of five regional service centers and nationwide force of over 200 Field Service Representatives put the industry’s best service where it belongs – close to you.

- Routine & Preventative Maintenance

- Technical Support & Diagnostics

- Field Service

- Request an Equipment Manual

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615

Service & Repairs: 616-698-7500

24/7 Parts: 1-800-727-8780

sale@inlandmachineokc.com

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

-

With a customized Stiles University course, we can provide expert training for your team, on-location. Whether it's programming, operation or maintenance, we want to help you train your personnel to meet your production goals efficiently and effectively.

-

Experience the trusted workforce development training and machinery knowledge you rely on from Stiles University, now at your convenience. With technology changing every day and new methods being developed constantly, Stiles University Online has the latest information and training content available at your fingertips.

-

Your solution for workforce development.

616-698-7500

-

-

-

Do you want to produce more efficiently? Processes and flows are key. We optimize these together with you, re-organize them and make sure that you reduce your lead time and save costs. This enables you to implement customized manufacturing and achieve your business goals.

-

Industrialized construction is evolving. Automation, robotics and advanced technology are raising the level of productivity, efficiency and precision for builders in North America.

-

Stiles Machinery is at the forefront of providing technology and machining for producing high quality mass timber. Automated solutions for your mass timber production can increase your manufacturing quality and productivity.

-

Project management services from Stiles make it easy to streamline your entire project— from concept and consultation to integration and implementation.

-

- Online Store

- News

- Careers

- REQUEST INFO

- Home

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

- TECHNICAL SUPPORT

- FIELD SERVICE

- ROUTINE & PREVENTATIVE MAINTENANCE

- REQUEST AN EQUIPMENT MANUAL

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615 Service & Repairs: 616-698-7500 24/7 Parts: 1-800-727-8780

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

- IN-PERSON TRAINING

- CUSTOMIZED COURSES & TRAINING

- STILES UNIVERSITY ONLINE

-

Your solution for workforce development.

- Online Store

- News

- Careers

- FINANCING

- Blog

- REQUEST INFO

- Home

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

- TECHNICAL SUPPORT

- FIELD SERVICE

- ROUTINE & PREVENTATIVE MAINTENANCE

- REQUEST AN EQUIPMENT MANUAL

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615 Service & Repairs: 616-698-7500 24/7 Parts: 1-800-727-8780

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

- IN-PERSON TRAINING

- CUSTOMIZED COURSES & TRAINING

- STILES UNIVERSITY ONLINE

-

Your solution for workforce development.

- Online Store

- News

- Careers

- FINANCING

- Blog

- REQUEST INFO

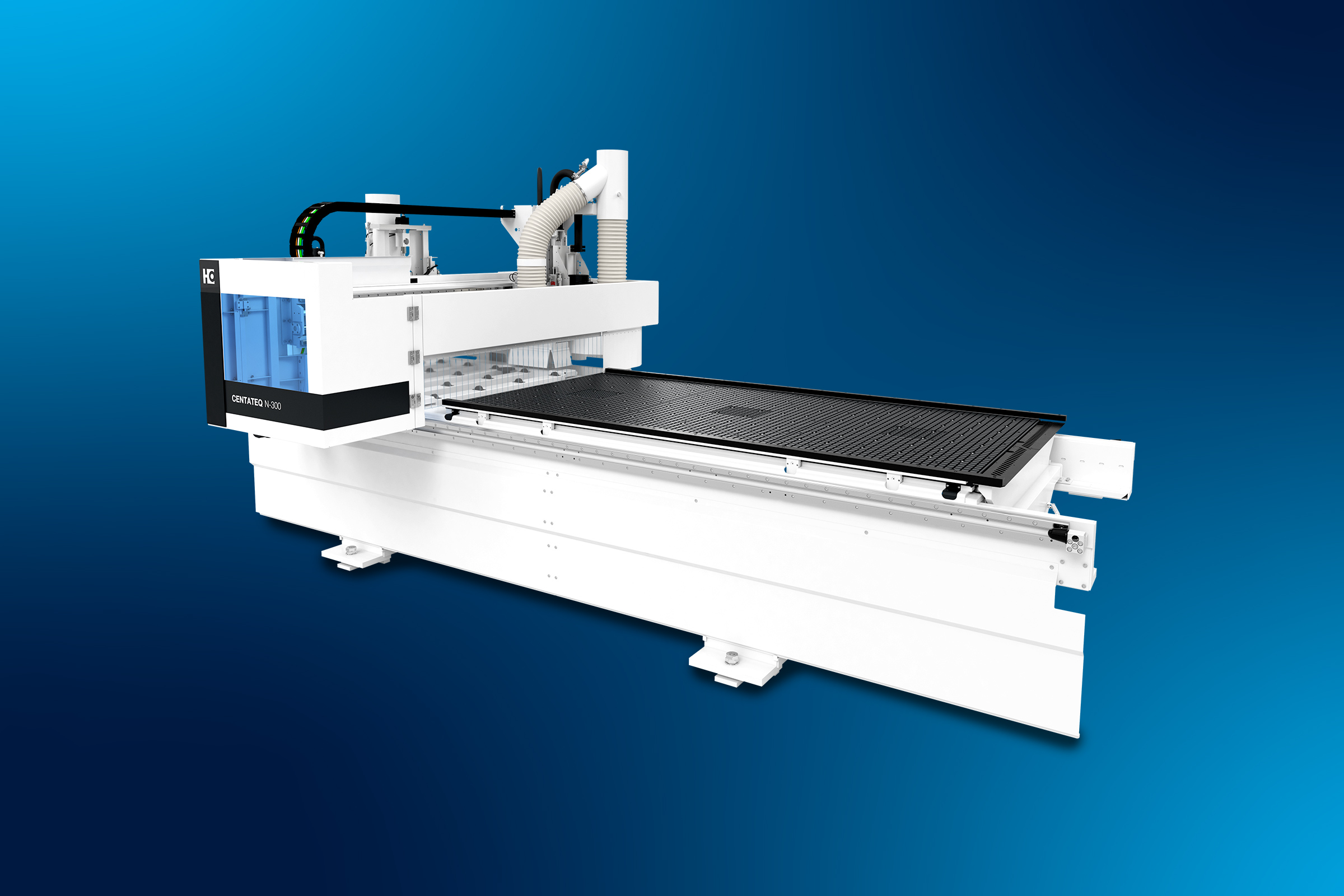

Exploring the Amazing World of CNC Routers for DIY Enthusiasts

As the maker movement continues to gain momentum, CNC routers have emerged as a game-changing tool for DIY enthusiasts seeking precision and versatility in their projects. According to a report by Grand View Research, the global CNC machine market is projected to reach USD 100 billion by 2025, with a significant portion driven by the rising demand for automated solutions in woodworking, metalworking, and prototyping. These machines not only enable users to create intricate designs but also enhance efficiency and reduce material waste.

With advancements in user-friendly software and affordable hardware options, CNC routers are becoming accessible to hobbyists and professionals alike. This exploration of the amazing world of CNC routers will delve into their benefits, applications, and the impact they have on the DIY community, providing insights that can inspire creators to harness the full potential of this remarkable technology.

Understanding the Basics of CNC Routers for DIY Projects

CNC routers have revolutionized the DIY landscape by providing enthusiasts with the tools to create intricate designs from various materials. Understanding the basics of CNC routers is essential for anyone looking to dive into this exciting realm. At its core, a CNC router is a computer-controlled cutting machine that can carve, engrave, and shape materials like wood, plastic, and metal. Users input designs through specialized software, and the machine translates these digital plans into physical creations, allowing for high precision and creativity.

One of the key aspects to comprehend is the different components that make up a CNC router. The primary elements include the frame, spindle, controller, and the tooling that determines the type of cuts possible. Hobbyists should also familiarize themselves with the software programs available, as they play a crucial role in design preparation and machining processes. Whether it's creating custom furniture, detailed artwork, or functional parts, understanding how these machines operate opens up a world of possibilities for DIY projects, enabling makers to express their creativity and push the boundaries of traditional crafting.

Exploring the Amazing World of CNC Routers for DIY Enthusiasts

| Feature | Description | Typical Uses |

|---|---|---|

| Cutting Area | The maximum size of material the CNC router can handle. | Furniture, signs, art pieces |

| Material Compatibility | Types of materials that can be cut or shaped. | Wood, plastics, soft metals |

| Software | Programs used to design and control the CNC router. | CAD/CAM software for design and toolpath generation |

| Precision | The level of accuracy in cutting and engraving. | Customized designs, intricate details |

| Ease of Use | User-friendliness of the machine interface. | Hobby projects, educational use |

| Price Range | Cost of CNC routers varying by features. | Affordable options for beginners, premium for professionals |

Choosing the Right CNC Router for Your Home Workshop

When choosing the right CNC router for your home workshop, it’s crucial to consider your specific needs and the types of projects you plan to undertake. First, assess the size of the projects you will be working on. Smaller CNC routers are ideal for intricate designs and detailed work on materials such as wood, plastic, or soft metals, while larger models can accommodate bigger projects like furniture or larger signs. Additionally, consider the router's cutting area, which varies widely among models, to ensure it meets the dimensions of your intended projects.

Another essential factor is the router's ease of use and the software compatibility. Look for CNC routers that come with user-friendly software, especially if you are new to CNC machining. Some models offer built-in features that simplify design and programming processes, which can be advantageous for DIY enthusiasts. Don't forget to evaluate the machine's power and speed, as these will directly impact your workflow efficiency and the quality of the final product. Ultimately, the right CNC router will empower your creativity and enhance your ability to bring your projects to life with precision and ease.

Essential Tools and Accessories for CNC Router Operation

When it comes to operating CNC routers, the right tools and accessories are crucial for achieving precision and efficiency. A recent report from the Association for Manufacturing Technology (AMT) indicated that nearly 70% of CNC operators attribute their success to investing in high-quality tools and supporting equipment. Essential accessories such as collets, bits, and dust collection systems enhance the overall performance of a CNC router, enabling DIY enthusiasts to tackle projects ranging from intricate designs to larger, more complex applications.

Collets and router bits are fundamental to the functioning of CNC routers. High-speed steel (HSS) and carbide bits are popular choices among DIY enthusiasts for their durability and cutting efficiency. According to a survey by Woodworking Network, users report that selecting the right bit can reduce project completion time by as much as 30%. Additionally, dust collection systems are not just about cleanliness; they play a critical role in maintaining a safe and efficient workspace. Effective dust management can decrease the risk of equipment damage and prolong the lifespan of tools, as noted in a study by the National Institute of Occupational Safety and Health (NIOSH), which highlighted that inadequate dust control can lead to significant increases in maintenance costs.

Step-by-Step Guide to Creating Your First CNC Project

Embarking on your first CNC project can be an exciting journey, especially for DIY enthusiasts eager to explore the boundless possibilities that CNC routers offer. To begin, it’s essential to choose a straightforward design that you can complete within a few hours. Consider crafting something practical, like a custom sign or a small decorative piece. This approach allows you to familiarize yourself with the CNC router’s capabilities while also yielding a tangible result that showcases your creativity.

Once you've selected your project, the next step is to prepare your design using software tailored for CNC programming. Programs like Fusion 360 or Easel can assist you in creating a digital blueprint. After finalizing your design, you’ll need to set up your CNC router, ensuring that the machine is properly calibrated and the correct tooling is in place. Finally, load your material, test the settings with a simulation, and watch as your CNC router brings your creation to life. This meticulous process not only enhances your technical skills but also ignites your passion for DIY projects with advanced technology.

Exploring the Amazing World of CNC Routers: Project Completion Times

Tips for Troubleshooting Common CNC Router Issues

When diving into the world of CNC routers, DIY enthusiasts can sometimes face a range of issues that might hinder their projects. Common problems include issues with the software, machine calibration, and material feed. One effective troubleshooting technique is to ensure that the software settings match the material specifications. Incorrect feed rates or tool paths can lead to imperfect cuts, so carefully reviewing these settings can often resolve issues before they escalate.

Another frequent challenge is machine calibration. If your CNC router is not cutting accurately, it could be a sign that the machine needs recalibration. Start by checking the alignment of the router bits and ensure they are securely fastened. Additionally, inspecting the rails for any debris or obstructions can help maintain smooth operation. Regular maintenance, such as lubricating moving parts and checking for wear, is key to preventing these problems from arising in the first place. By addressing these common issues proactively, DIY enthusiasts can enhance their CNC routing experience and achieve precise results in their projects.

Related Posts

-

Unlocking the Potential of Wood CNC Machines for Your Next Creative Project

-

Exploring the Future of Manufacturing: How CNC Machines are Revolutionizing Production Techniques

-

Revolutionizing Furniture Manufacturing: How Edge Banding Machines Enhance Production Efficiency

-

The Ultimate Guide to Choosing the Best Sanding Machine for Your DIY Projects