- Home

-

-

-

Stiles Enhancement Technologies

-

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

-

-

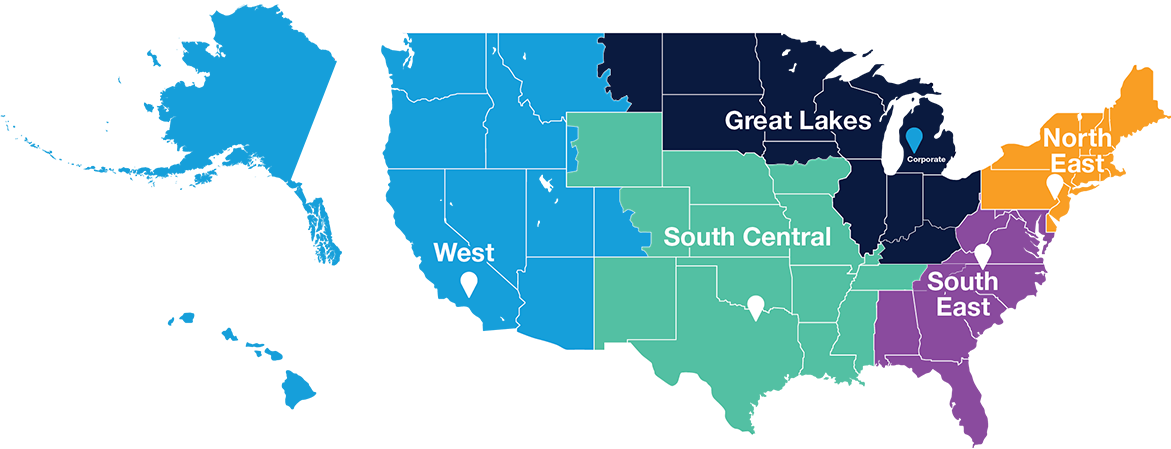

- Stiles Machinery hosts a national network of five regional service centers and nationwide force of over 200 Field Service Representatives put the industry’s best service where it belongs – close to you.

- Routine & Preventative Maintenance

- Technical Support & Diagnostics

- Field Service

- Request an Equipment Manual

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615

Service & Repairs: 616-698-7500

24/7 Parts: 1-800-727-8780

sale@inlandmachineokc.com

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

-

With a customized Stiles University course, we can provide expert training for your team, on-location. Whether it's programming, operation or maintenance, we want to help you train your personnel to meet your production goals efficiently and effectively.

-

Experience the trusted workforce development training and machinery knowledge you rely on from Stiles University, now at your convenience. With technology changing every day and new methods being developed constantly, Stiles University Online has the latest information and training content available at your fingertips.

-

Your solution for workforce development.

616-698-7500

-

-

-

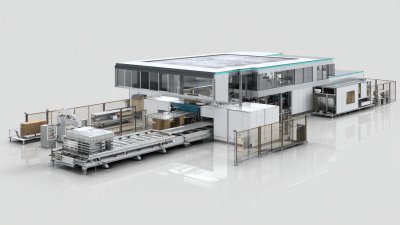

Do you want to produce more efficiently? Processes and flows are key. We optimize these together with you, re-organize them and make sure that you reduce your lead time and save costs. This enables you to implement customized manufacturing and achieve your business goals.

-

Industrialized construction is evolving. Automation, robotics and advanced technology are raising the level of productivity, efficiency and precision for builders in North America.

-

Stiles Machinery is at the forefront of providing technology and machining for producing high quality mass timber. Automated solutions for your mass timber production can increase your manufacturing quality and productivity.

-

Project management services from Stiles make it easy to streamline your entire project— from concept and consultation to integration and implementation.

-

- Online Store

- News

- Careers

- REQUEST INFO

- Home

-

-

-

Stiles Enhancement Technologies

-

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

-

-

- Stiles Machinery hosts a national network of five regional service centers and nationwide force of over 200 Field Service Representatives put the industry’s best service where it belongs – close to you.

- Routine & Preventative Maintenance

- Technical Support & Diagnostics

- Field Service

- Request an Equipment Manual

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615

Service & Repairs: 616-698-7500

24/7 Parts: 1-800-727-8780

sale@inlandmachineokc.com

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

-

With a customized Stiles University course, we can provide expert training for your team, on-location. Whether it's programming, operation or maintenance, we want to help you train your personnel to meet your production goals efficiently and effectively.

-

Experience the trusted workforce development training and machinery knowledge you rely on from Stiles University, now at your convenience. With technology changing every day and new methods being developed constantly, Stiles University Online has the latest information and training content available at your fingertips.

-

Your solution for workforce development.

616-698-7500

-

-

-

Do you want to produce more efficiently? Processes and flows are key. We optimize these together with you, re-organize them and make sure that you reduce your lead time and save costs. This enables you to implement customized manufacturing and achieve your business goals.

-

Industrialized construction is evolving. Automation, robotics and advanced technology are raising the level of productivity, efficiency and precision for builders in North America.

-

Stiles Machinery is at the forefront of providing technology and machining for producing high quality mass timber. Automated solutions for your mass timber production can increase your manufacturing quality and productivity.

-

Project management services from Stiles make it easy to streamline your entire project— from concept and consultation to integration and implementation.

-

- Online Store

- News

- Careers

- REQUEST INFO

- Home

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

- TECHNICAL SUPPORT

- FIELD SERVICE

- ROUTINE & PREVENTATIVE MAINTENANCE

- REQUEST AN EQUIPMENT MANUAL

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615 Service & Repairs: 616-698-7500 24/7 Parts: 1-800-727-8780

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

- IN-PERSON TRAINING

- CUSTOMIZED COURSES & TRAINING

- STILES UNIVERSITY ONLINE

-

Your solution for workforce development.

- Online Store

- News

- Careers

- FINANCING

- Blog

- REQUEST INFO

- Home

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

- TECHNICAL SUPPORT

- FIELD SERVICE

- ROUTINE & PREVENTATIVE MAINTENANCE

- REQUEST AN EQUIPMENT MANUAL

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615 Service & Repairs: 616-698-7500 24/7 Parts: 1-800-727-8780

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

- IN-PERSON TRAINING

- CUSTOMIZED COURSES & TRAINING

- STILES UNIVERSITY ONLINE

-

Your solution for workforce development.

- Online Store

- News

- Careers

- FINANCING

- Blog

- REQUEST INFO

2026 How to Choose the Right CNC Mill for Your Workshop Needs?

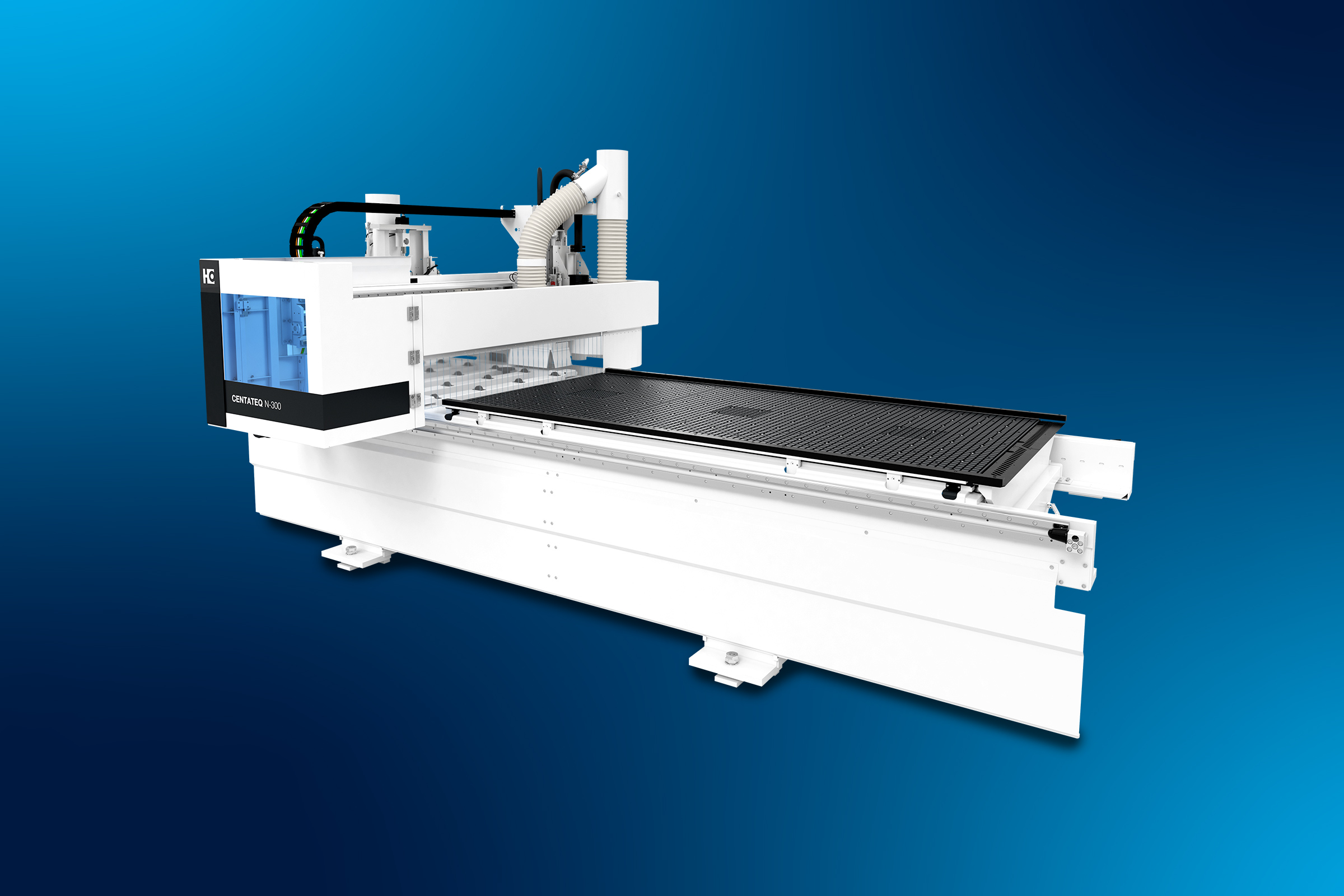

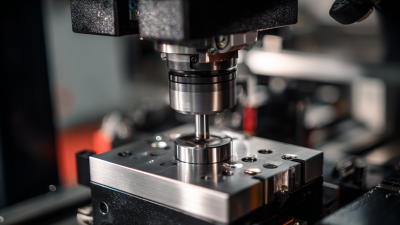

Choosing the right CNC mill for your workshop can greatly impact your projects. An expert in the field, John Smith, emphasizes, "A CNC mill is a vital investment for precision machining." Understanding your specific needs is crucial.

CNC mills come in various sizes and configurations. Factors such as material type and desired precision affect your choice. It’s essential to evaluate these elements carefully. For smaller shops, a compact CNC mill may suffice. However, larger operations might require more robust models.

Reflecting on your workshop's capabilities is necessary. Consider training needs and equipment maintenance. Investing in a CNC mill isn't just about the machine itself. It's about the potential it unlocks for your craft. Thoughtful consideration leads to better decisions.

Understanding CNC Milling: Core Concepts and Applications

CNC milling is a vital process in modern machining. It allows for precision shaping of various materials. Understanding its core concepts helps in choosing the right machine. CNC stands for Computer Numerical Control. It automates the milling process, making it more efficient.

When considering CNC milling, think about the materials you'll work with. Aluminum, steel, and plastic each require different settings. Evaluate the sizes of parts you intend to mill. Larger parts may require a robust CNC mill. Also, consider the complexity of the designs you want to create. Some mills are better suited for intricate tasks than others.

**Tips:** Always review the machine's specifications. Ensure it meets your workshop's needs. Test your designs on a smaller scale. This can prevent costly mistakes. Additionally, ask experienced users for insights. They often have valuable advice on machine performance. Don't overlook the importance of maintenance. Regular checks can extend your machine's life significantly.

2026 How to Choose the Right CNC Mill for Your Workshop Needs?

| Model | Type | X-Axis Travel (mm) | Y-Axis Travel (mm) | Z-Axis Travel (mm) | Spindle Speed (RPM) | Price (USD) |

|---|---|---|---|---|---|---|

| CNC Mill A | Vertical | 600 | 400 | 300 | 10000 | 5000 |

| CNC Mill B | Horizontal | 800 | 500 | 400 | 12000 | 8000 |

| CNC Mill C | Benchtop | 400 | 300 | 200 | 8000 | 2500 |

| CNC Mill D | 5-Axis | 700 | 500 | 400 | 15000 | 15000 |

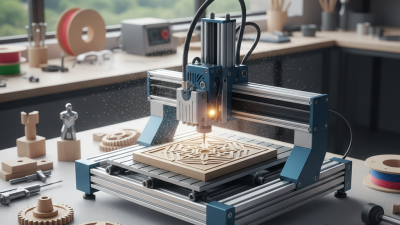

Evaluating Your Workshop Needs for CNC Milling Machines

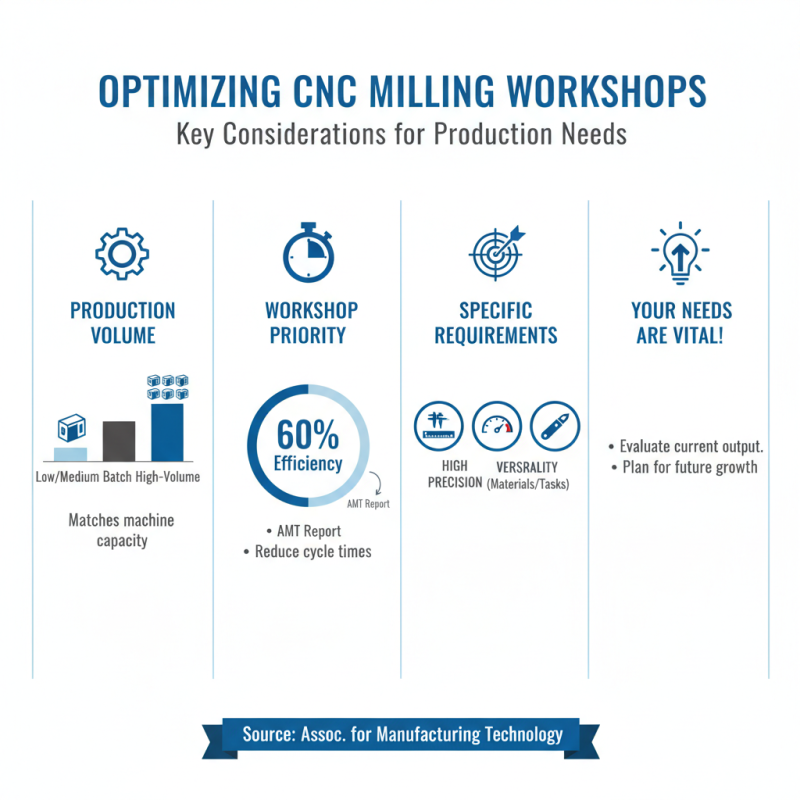

When evaluating workshop needs for CNC milling machines, consider your production volume. A report by the Association for Manufacturing Technology highlights that 60% of workshops prioritize efficiency. Understanding your specific requirements is vital. Do you need high precision, speed, or versatility?

Next, think about the materials you will be working with. If you primarily mill aluminum, a different machine specification might apply compared to steel or composites. According to a recent survey, almost 50% of CNC users report that material types significantly influence their machine choice. What are the common issues you face with your current setups?

Space and budget constraints are often overlooked. Compact machines can be optimal for smaller workshops. However, they may limit potential production scalability. How do you balance cost and functionality? Examining these factors can help tailor a solution that fits your unique setup.

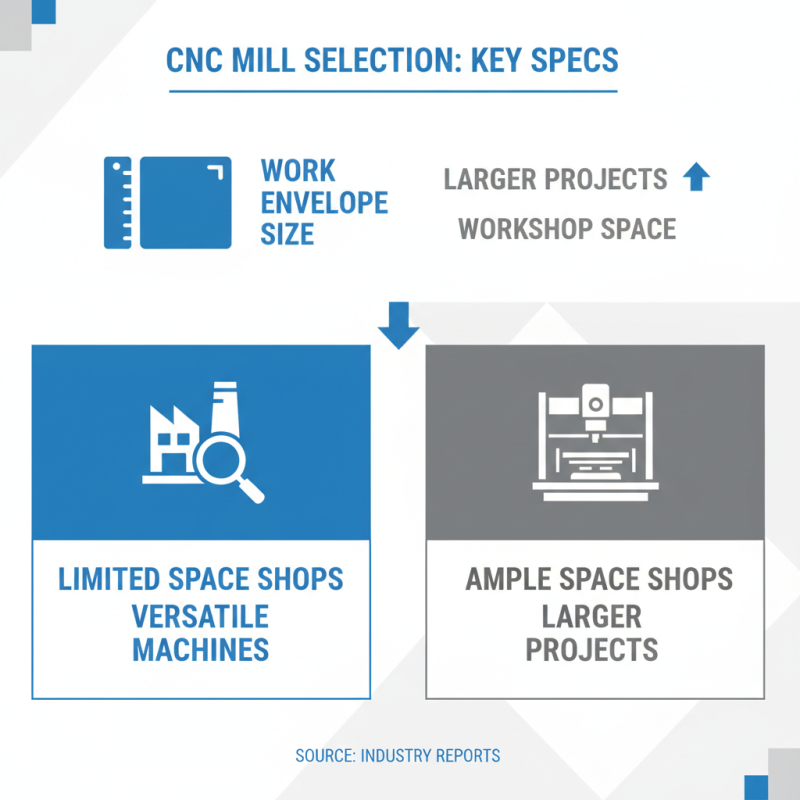

Key Specifications to Consider When Choosing a CNC Mill

When selecting a CNC mill, key specifications play a crucial role. The size of the work envelope is paramount. A larger envelope allows for bigger projects. However, not every workshop has ample space. This could restrict options. According to industry reports, shops with limited footprint often need versatile machines.

Another important factor is the spindle speed. Higher speeds enable quicker cuts but can generate heat. Heat management becomes vital in such cases. Many reports suggest around 10,000 RPM is a sweet spot for various materials. Yet, if a mill runs too hot, it can impact the quality of the finish. It’s a delicate balance that needs consideration.

Tooling options also matter greatly. The ability to use different tool types can enhance functionality. Many machines come with a specific toolholder system. Understanding the compatibility of tools is essential. Relying on a limited range may hinder project versatility. Reports indicate that diverse tooling can boost productivity by up to 30%. If a workshop lacks appropriate tooling, inefficiencies will arise. A thorough evaluation of these key specifications ensures a more suitable choice for your workshop.

Comparative Analysis of Popular CNC Mill Brands and Models

When choosing a CNC mill, comparing popular brands and models is crucial. Different machines serve distinct purposes, and knowing your needs can save you time and money. Some CNC mills are designed for heavy-duty use, while others are more suited for intricate work. Pay attention to the machine's specifications, such as spindle speed and cutting capacity.

Tips: Look for machines that offer versatility. A multi-functional mill can adapt to various tasks. Additionally, consider customer reviews. They can provide insight into reliability and performance.

Evaluate the support and warranty provided by manufacturers. A good warranty can give peace of mind. But, be wary of overly complex setups. Sometimes, a simple machine can offer great results.

Tip: Invest in training if you're new to CNC milling. Proper knowledge can unlock the potential of your machine. Keep in mind that the best choice may not always be the most expensive. Find a balance between features and your workshop needs.

Cost-Benefit Assessment of CNC Mills for Small vs. Large Workshops

Choosing the right CNC mill for your workshop is crucial. The cost-benefit analysis shows notable differences based on workshop size. Small workshops often operate on tight budgets. A recent industry report indicated that small CNC mills can cost between $5,000 and $20,000. They provide adequate functionality for limited production needs. However, the output often doesn't justify the investment for larger projects.

In contrast, larger workshops may spend significantly more. High-end CNC mills can range from $50,000 to over $100,000. While this seems daunting, they offer advanced capabilities and faster production rates. A recent study found that larger mills can increase productivity by up to 40% compared to their smaller counterparts. This gap may surprise many. Some argue that small mills are sufficient for prototyping; yet, they can become bottlenecks in scaling production.

On the flip side, maintenance and operational costs are critical considerations. According to a report from the National Institute of Standards and Technology, about 15% of CNC mill operating costs arise from maintenance. Small workshop owners must weigh these costs carefully. Is a budget-friendly option a wise choice if it leads to higher long-term expenses? They must reflect on their specific needs. Choosing the right CNC mill entails more than upfront costs. It requires a full assessment of long-term benefits and limitations.

Cost-Benefit Assessment of CNC Mills for Small vs. Large Workshops

This chart illustrates a cost-benefit assessment for CNC mills used in small and large workshops, highlighting initial costs, annual operating costs, and expected return on investment (ROI) percentages.

Related Posts

-

Top 10 Small CNC Machines for Precision Engineering in 2023

-

Top 5 CNC Router Kits for Precision Crafting and DIY Projects

-

Top 5 CNC Router Kits for Ultimate Precision and DIY Projects in 2023

-

Revolutionizing Furniture Manufacturing: How Edge Banding Machines Enhance Production Efficiency

-

Essential Tips for Choosing the Right Rotary Screw Compressor for Your Needs

-

Exploring the Future of Manufacturing: How CNC Machines are Revolutionizing Production Techniques