- Home

-

-

-

Stiles Enhancement Technologies

-

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

-

-

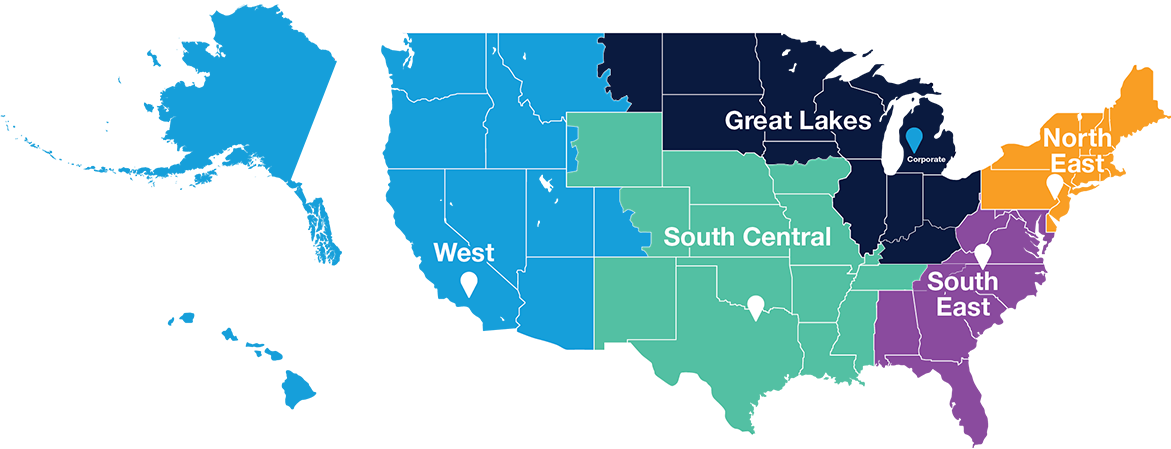

- Stiles Machinery hosts a national network of five regional service centers and nationwide force of over 200 Field Service Representatives put the industry’s best service where it belongs – close to you.

- Routine & Preventative Maintenance

- Technical Support & Diagnostics

- Field Service

- Request an Equipment Manual

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615

Service & Repairs: 616-698-7500

24/7 Parts: 1-800-727-8780

sale@inlandmachineokc.com

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

-

With a customized Stiles University course, we can provide expert training for your team, on-location. Whether it's programming, operation or maintenance, we want to help you train your personnel to meet your production goals efficiently and effectively.

-

Experience the trusted workforce development training and machinery knowledge you rely on from Stiles University, now at your convenience. With technology changing every day and new methods being developed constantly, Stiles University Online has the latest information and training content available at your fingertips.

-

Your solution for workforce development.

616-698-7500

-

-

-

Do you want to produce more efficiently? Processes and flows are key. We optimize these together with you, re-organize them and make sure that you reduce your lead time and save costs. This enables you to implement customized manufacturing and achieve your business goals.

-

Industrialized construction is evolving. Automation, robotics and advanced technology are raising the level of productivity, efficiency and precision for builders in North America.

-

Stiles Machinery is at the forefront of providing technology and machining for producing high quality mass timber. Automated solutions for your mass timber production can increase your manufacturing quality and productivity.

-

Project management services from Stiles make it easy to streamline your entire project— from concept and consultation to integration and implementation.

-

- Online Store

- News

- Careers

- REQUEST INFO

- Home

-

-

-

Stiles Enhancement Technologies

-

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

-

-

- Stiles Machinery hosts a national network of five regional service centers and nationwide force of over 200 Field Service Representatives put the industry’s best service where it belongs – close to you.

- Routine & Preventative Maintenance

- Technical Support & Diagnostics

- Field Service

- Request an Equipment Manual

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615

Service & Repairs: 616-698-7500

24/7 Parts: 1-800-727-8780

sale@inlandmachineokc.com

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

-

With a customized Stiles University course, we can provide expert training for your team, on-location. Whether it's programming, operation or maintenance, we want to help you train your personnel to meet your production goals efficiently and effectively.

-

Experience the trusted workforce development training and machinery knowledge you rely on from Stiles University, now at your convenience. With technology changing every day and new methods being developed constantly, Stiles University Online has the latest information and training content available at your fingertips.

-

Your solution for workforce development.

616-698-7500

-

-

-

Do you want to produce more efficiently? Processes and flows are key. We optimize these together with you, re-organize them and make sure that you reduce your lead time and save costs. This enables you to implement customized manufacturing and achieve your business goals.

-

Industrialized construction is evolving. Automation, robotics and advanced technology are raising the level of productivity, efficiency and precision for builders in North America.

-

Stiles Machinery is at the forefront of providing technology and machining for producing high quality mass timber. Automated solutions for your mass timber production can increase your manufacturing quality and productivity.

-

Project management services from Stiles make it easy to streamline your entire project— from concept and consultation to integration and implementation.

-

- Online Store

- News

- Careers

- REQUEST INFO

- Home

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

- TECHNICAL SUPPORT

- FIELD SERVICE

- ROUTINE & PREVENTATIVE MAINTENANCE

- REQUEST AN EQUIPMENT MANUAL

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615 Service & Repairs: 616-698-7500 24/7 Parts: 1-800-727-8780

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

- IN-PERSON TRAINING

- CUSTOMIZED COURSES & TRAINING

- STILES UNIVERSITY ONLINE

-

Your solution for workforce development.

- Online Store

- News

- Careers

- FINANCING

- Blog

- REQUEST INFO

- Home

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

- TECHNICAL SUPPORT

- FIELD SERVICE

- ROUTINE & PREVENTATIVE MAINTENANCE

- REQUEST AN EQUIPMENT MANUAL

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615 Service & Repairs: 616-698-7500 24/7 Parts: 1-800-727-8780

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

- IN-PERSON TRAINING

- CUSTOMIZED COURSES & TRAINING

- STILES UNIVERSITY ONLINE

-

Your solution for workforce development.

- Online Store

- News

- Careers

- FINANCING

- Blog

- REQUEST INFO

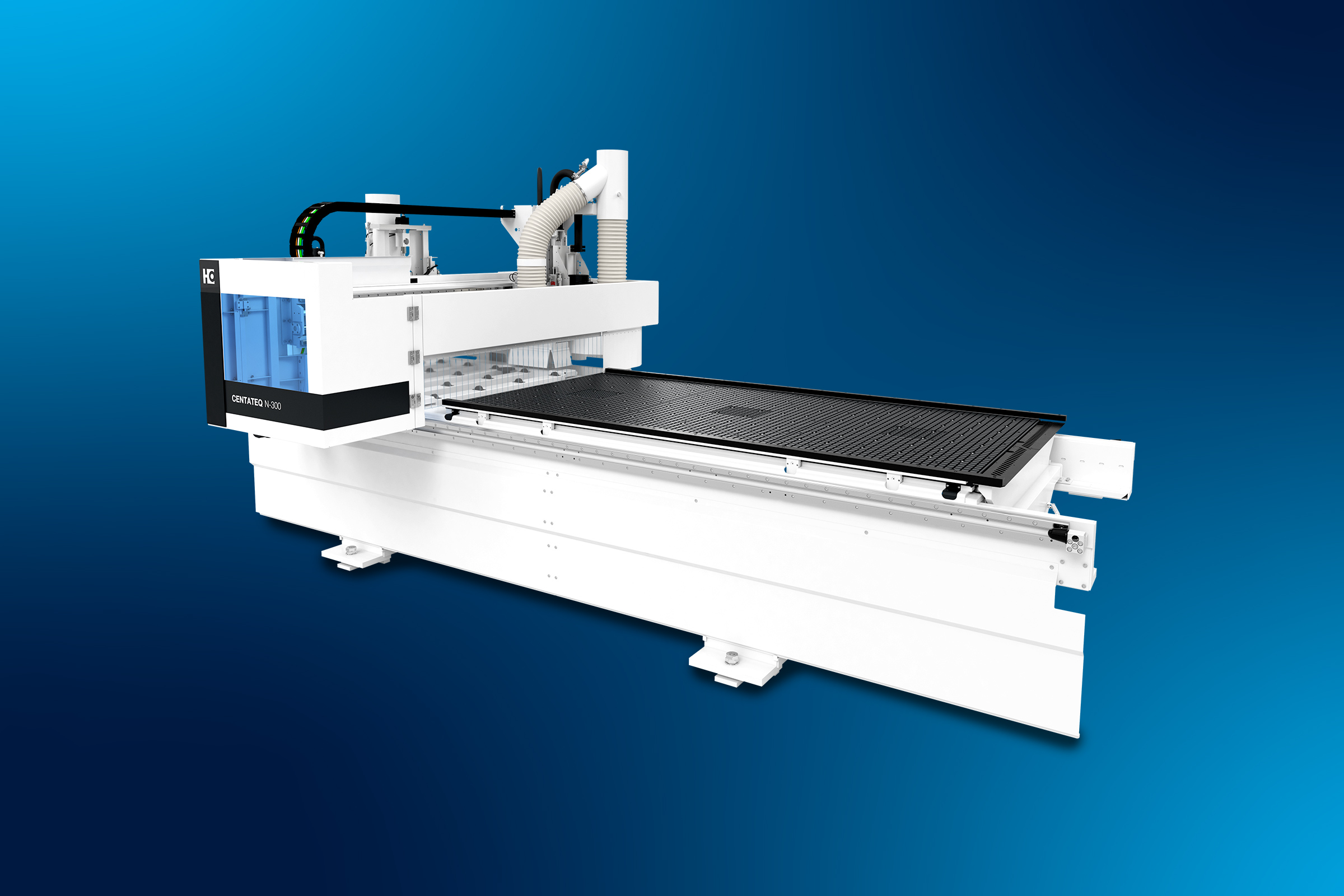

2026 How to Choose the Best Panel Saw for Your Workshop Needs?

Choosing the right panel saw for your workshop can be challenging. With so many options available, it’s easy to feel overwhelmed. Understanding what makes a great panel saw is key.

Your workshop needs will greatly influence your choice. Consider the size and type of materials you typically cut. A panel saw should fit seamlessly into your workflow. Look for features that enhance precision and efficiency. Yet, it is essential not to rush the decision. Each saw has unique benefits and drawbacks.

Budget considerations play a crucial role too. Sometimes, the most expensive option isn’t necessarily the best for your specific needs. Reflecting on your long-term goals helps clarify your priorities. A well-chosen panel saw can elevate your craftsmanship significantly.

Understanding Different Types of Panel Saws Available on the Market

When selecting a panel saw, understanding the different types is crucial. There are two main categories: vertical and sliding.

Vertical panel saws are compact and great for small workshops. They handle thick sheets easily. Sliding panel saws, on the other hand, offer precision for larger projects. They can handle larger sheets without losing accuracy.

Tips: Always consider the available space in your workshop. Measure your area before making a decision.

There are also manual and power options. Manual saws are simple and affordable. They require more physical effort but can be satisfying to use. Power saws offer speed and efficiency. However, they can be more expensive.

Tips: If you are a beginner, a manual option might help you understand the process better. It teaches you the fundamentals of cutting angles and measurements.

Investing in a panel saw is a big decision. Ensure to research the features that suit your needs best. Sometimes, the most expensive option isn't the right one. Reflect on what you truly need for your projects.

Key Features to Consider When Selecting a Panel Saw for Your Workshop

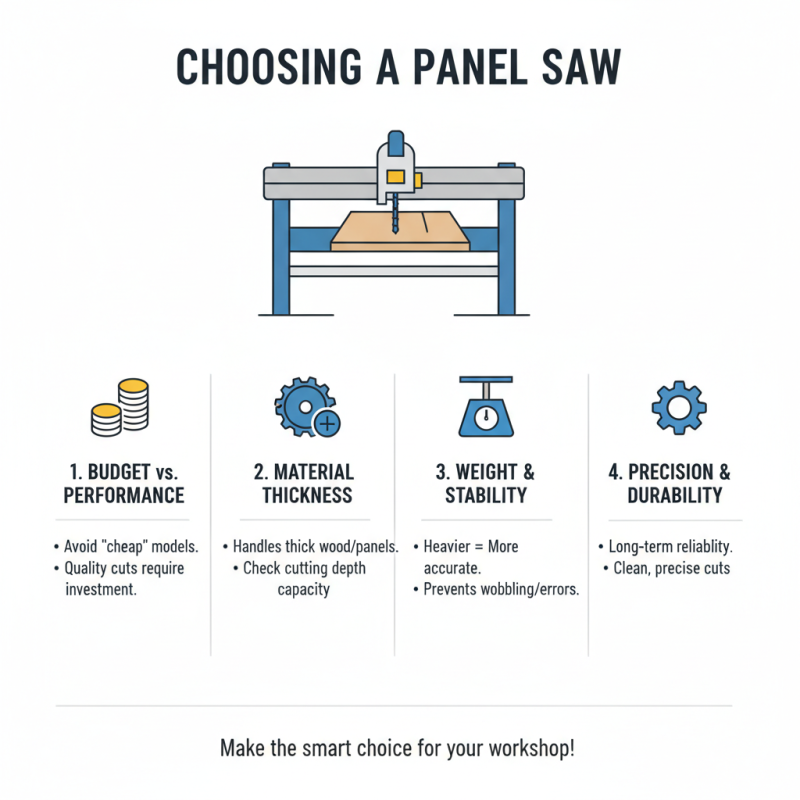

When selecting a panel saw for your workshop, you must consider several key features. The blade size is crucial. Most panel saws come with blades ranging from 8 to 12 inches. Larger blades increase cutting capacity but can be heavier. A 2019 industry report indicates that 70% of professionals prefer 10-inch blades for versatility.

Another important aspect is the power of the motor. A motor rated between 2 and 5 horsepower is common. Higher horsepower allows for cutting thicker materials more efficiently. However, some users find that high-power models can be overkill for basic tasks. Noise levels also vary significantly. According to a 2020 study, up to 40% of users have issues with excess noise, affecting comfort and concentration in workshops.

Consider the weight and portability of the saw. Some models can weigh over 300 pounds, making them more stable but less mobile. This may not be ideal for workshops with limited space. Features like dust collection and measurement systems are also worth your attention. Industry surveys show that up to 60% of users value effective dust collection, emphasizing the need for a cleaner workspace.

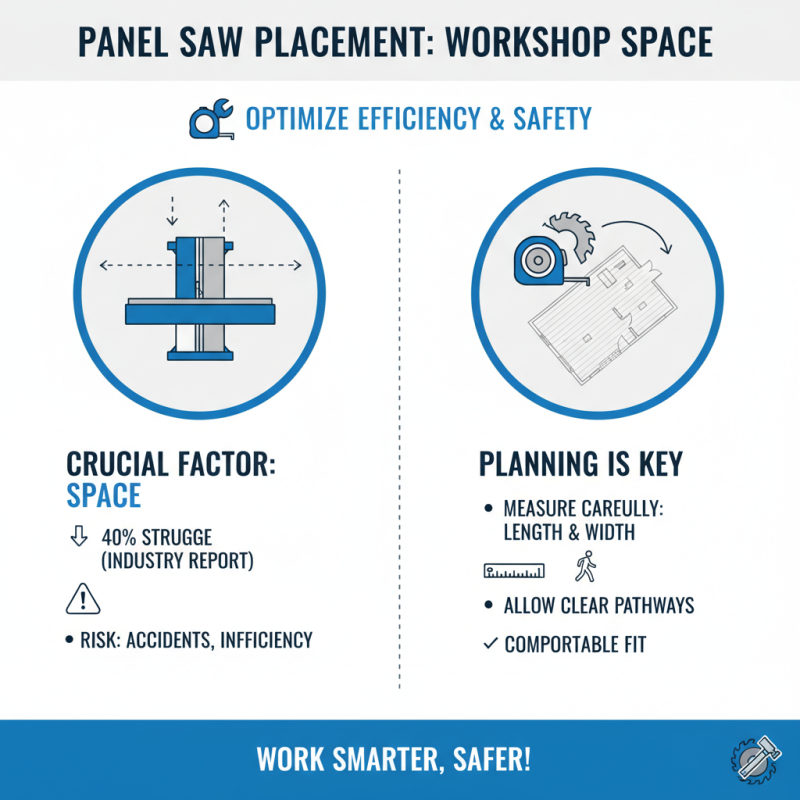

Assessing Your Workshop Space: Size and Placement for a Panel Saw

When choosing a panel saw, workshop space is crucial. A well-organized area can enhance efficiency. According to a recent industry report, nearly 40% of woodworkers struggle with inadequate space. This can lead to accidents and inefficiency. Measure your area carefully. Consider the length and width of the panel saw. It should fit comfortably without obstructing pathways.

Placement is another vital factor. A panel saw needs ample room for infeed and outfeed. The recommended clearance is at least 6 feet on either side. Many users underestimate this requirement. In fact, 25% of panel saw accidents occur due to cramped spaces. Thoughtful positioning can prevent mishaps and improve workflow.

Reflect on your space layout. Are there any obstacles? Is your setup flexible? Poor planning can hinder productivity. A good arrangement promotes a safer environment. Take time to visualize your workspace. It’s easy to overlook these details in a busy shop. Adjustments today can lead to smoother operations tomorrow.

Evaluating Budget vs. Performance: Finding the Right Panel Saw

Choosing the right panel saw for your workshop can be challenging. Budget constraints often clash with performance requirements. It's easy to be tempted by lower-priced models, but they may not deliver the quality you need. Look for saws that can handle thick materials. Consider the weight and stability too. A lightweight model might be easier to maneuver, but it can lead to inaccuracies during cuts.

Performance isn’t just about power. Accuracy is crucial. Evaluate features like scoring blades and blade adjustments. These elements can significantly impact the quality of your cuts. Think about the types of projects you frequently tackle. Will the saw be used for large sheets, or is it more for smaller cuts? A well-rounded selection may require a more substantial investment but could save you money in the long run.

Become aware of your workshop’s limitations. Space can restrict the size of the saw you choose. Also, consider the noise level. Some saws are much louder than others. Did I mention safety? This should be part of your performance evaluation. Investing in safety features might increase costs, but peace of mind is priceless. Always weigh these factors against your budget to get the best value for your needs.

Safety Features and Maintenance Tips for Long-Lasting Panel Saws

When selecting a panel saw, safety features are paramount. The U.S. Bureau of Labor Statistics indicates that over 30,000 injuries occur annually in woodshops. A panel saw equipped with automatic shut-off systems can significantly reduce risks. Emergency stops are crucial. They allow for quick reactions in case of unexpected incidents. Consider blade guards and riving knives for added safety measures.

Maintenance plays a key role in a panel saw's longevity. Regularly inspecting the saw's alignment prevents operational issues. A misaligned saw can lead to poor cuts and potential safety hazards. According to industry reports, routine maintenance can extend equipment life by 30%. Keep blades sharp; dull blades require more force, increasing the chance of accidents. Lubricating moving parts will also enhance performance and reliability.

Reflecting on common oversights can lead to better practices. Many woodworkers neglect the importance of daily checks. Instead, they focus solely on projects. Ignoring maintenance can result in costly repairs or accidents. Prioritizing safety and upkeep ensures a safer workshop environment and maximizes productivity.

Related Posts

-

Unlocking Creativity: How CNC Wood Cutting Machines Transform Custom Furniture Design

-

The 10 Best Woodworking Machinery Tools You Need for Your Workshop

-

2025 Guide: How to Choose the Best CNC Machining Parts for Your Projects

-

The Ultimate Guide to Choosing the Best Sanding Machine for Your DIY Projects

-

Top 10 CNC Router Machine Features You Should Know Before Buying

-

2025 Top 5 Rotary Screw Air Compressors for Enhanced Performance