- Home

-

-

-

Stiles Enhancement Technologies

-

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

-

-

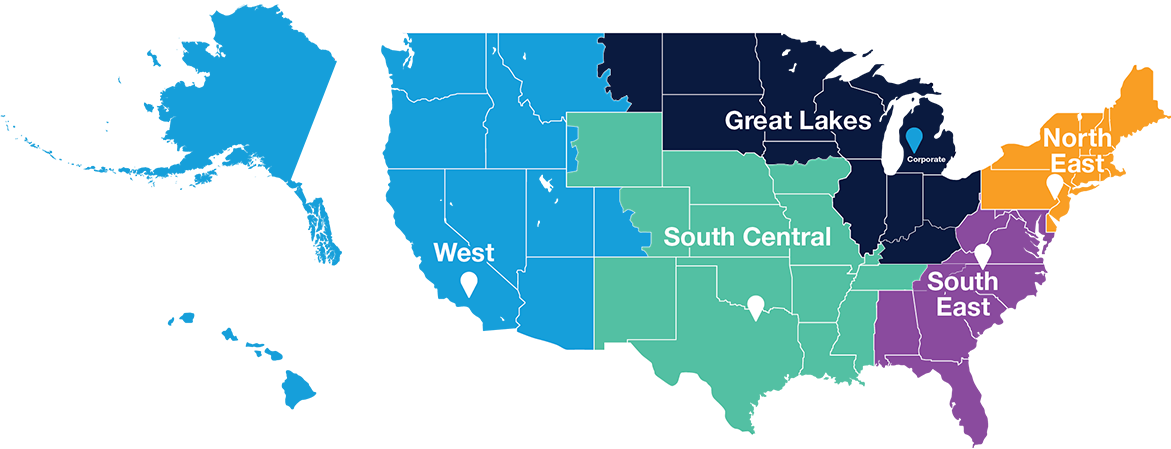

- Stiles Machinery hosts a national network of five regional service centers and nationwide force of over 200 Field Service Representatives put the industry’s best service where it belongs – close to you.

- Routine & Preventative Maintenance

- Technical Support & Diagnostics

- Field Service

- Request an Equipment Manual

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615

Service & Repairs: 616-698-7500

24/7 Parts: 1-800-727-8780

sale@inlandmachineokc.com

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

-

With a customized Stiles University course, we can provide expert training for your team, on-location. Whether it's programming, operation or maintenance, we want to help you train your personnel to meet your production goals efficiently and effectively.

-

Experience the trusted workforce development training and machinery knowledge you rely on from Stiles University, now at your convenience. With technology changing every day and new methods being developed constantly, Stiles University Online has the latest information and training content available at your fingertips.

-

Your solution for workforce development.

616-698-7500

-

-

-

Do you want to produce more efficiently? Processes and flows are key. We optimize these together with you, re-organize them and make sure that you reduce your lead time and save costs. This enables you to implement customized manufacturing and achieve your business goals.

-

Industrialized construction is evolving. Automation, robotics and advanced technology are raising the level of productivity, efficiency and precision for builders in North America.

-

Stiles Machinery is at the forefront of providing technology and machining for producing high quality mass timber. Automated solutions for your mass timber production can increase your manufacturing quality and productivity.

-

Project management services from Stiles make it easy to streamline your entire project— from concept and consultation to integration and implementation.

-

- Online Store

- News

- Careers

- REQUEST INFO

- Home

-

-

-

Stiles Enhancement Technologies

-

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

-

-

- Stiles Machinery hosts a national network of five regional service centers and nationwide force of over 200 Field Service Representatives put the industry’s best service where it belongs – close to you.

- Routine & Preventative Maintenance

- Technical Support & Diagnostics

- Field Service

- Request an Equipment Manual

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615

Service & Repairs: 616-698-7500

24/7 Parts: 1-800-727-8780

sale@inlandmachineokc.com

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

-

With a customized Stiles University course, we can provide expert training for your team, on-location. Whether it's programming, operation or maintenance, we want to help you train your personnel to meet your production goals efficiently and effectively.

-

Experience the trusted workforce development training and machinery knowledge you rely on from Stiles University, now at your convenience. With technology changing every day and new methods being developed constantly, Stiles University Online has the latest information and training content available at your fingertips.

-

Your solution for workforce development.

616-698-7500

-

-

-

Do you want to produce more efficiently? Processes and flows are key. We optimize these together with you, re-organize them and make sure that you reduce your lead time and save costs. This enables you to implement customized manufacturing and achieve your business goals.

-

Industrialized construction is evolving. Automation, robotics and advanced technology are raising the level of productivity, efficiency and precision for builders in North America.

-

Stiles Machinery is at the forefront of providing technology and machining for producing high quality mass timber. Automated solutions for your mass timber production can increase your manufacturing quality and productivity.

-

Project management services from Stiles make it easy to streamline your entire project— from concept and consultation to integration and implementation.

-

- Online Store

- News

- Careers

- REQUEST INFO

- Home

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

- TECHNICAL SUPPORT

- FIELD SERVICE

- ROUTINE & PREVENTATIVE MAINTENANCE

- REQUEST AN EQUIPMENT MANUAL

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615 Service & Repairs: 616-698-7500 24/7 Parts: 1-800-727-8780

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

- IN-PERSON TRAINING

- CUSTOMIZED COURSES & TRAINING

- STILES UNIVERSITY ONLINE

-

Your solution for workforce development.

- Online Store

- News

- Careers

- FINANCING

- Blog

- REQUEST INFO

- Home

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

- TECHNICAL SUPPORT

- FIELD SERVICE

- ROUTINE & PREVENTATIVE MAINTENANCE

- REQUEST AN EQUIPMENT MANUAL

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615 Service & Repairs: 616-698-7500 24/7 Parts: 1-800-727-8780

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

- IN-PERSON TRAINING

- CUSTOMIZED COURSES & TRAINING

- STILES UNIVERSITY ONLINE

-

Your solution for workforce development.

- Online Store

- News

- Careers

- FINANCING

- Blog

- REQUEST INFO

How to Choose the Best CNC Router Machine for Your Projects

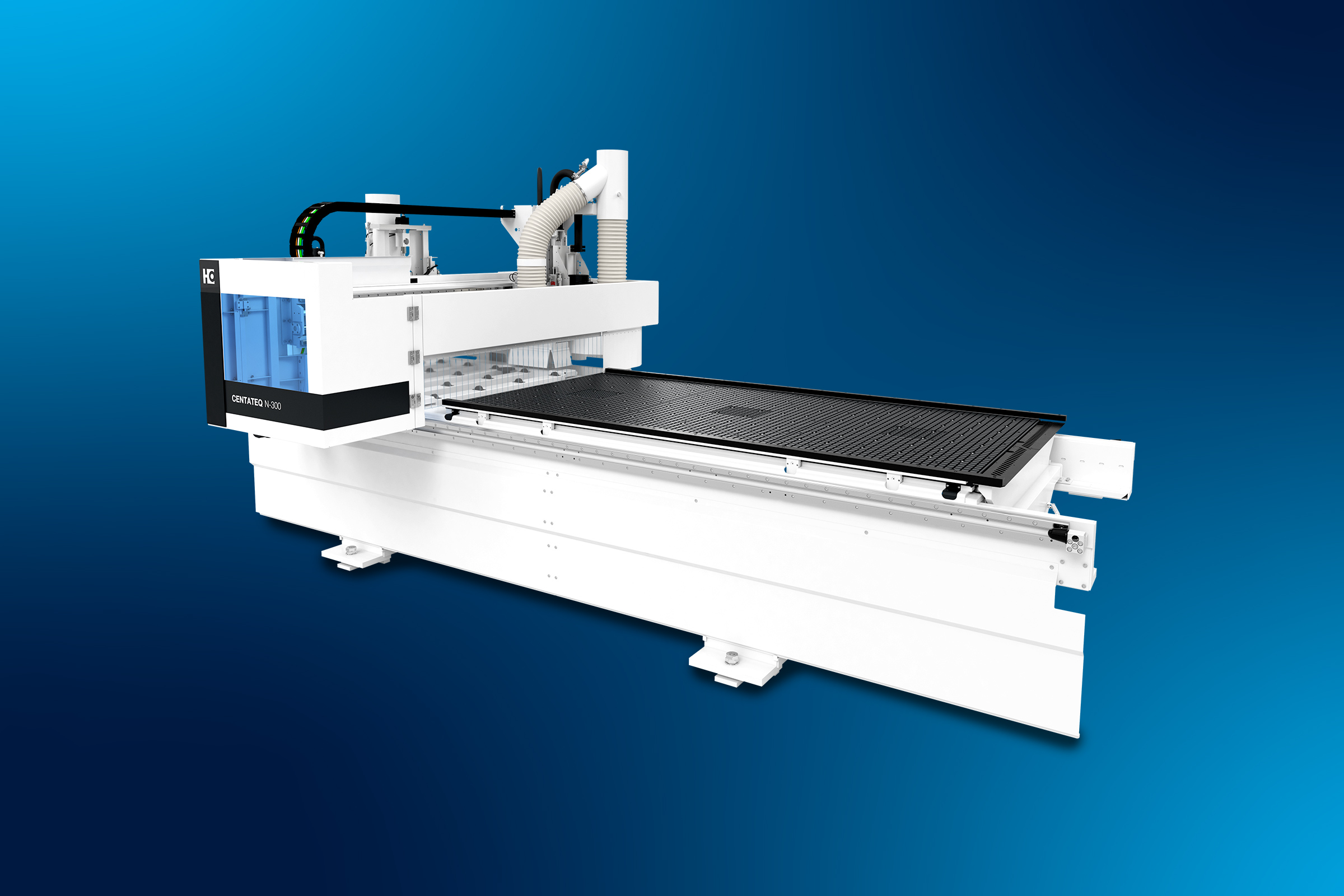

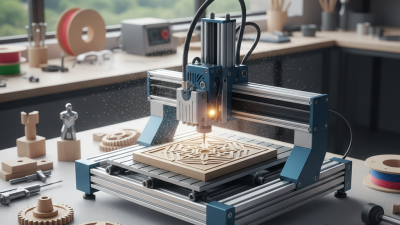

When embarking on a new project, the choice of the right equipment can significantly influence the outcome. One of the most versatile tools in modern fabrication is the CNC router machine. These machines have revolutionized woodworking, metalworking, and various other industries by allowing for precision cutting, carving, and engraving. However, with a plethora of options available on the market, selecting the best CNC router machine tailored to your specific needs can be a daunting task.

In this guide, we will explore essential factors to consider when choosing a CNC router machine. From understanding the different types and sizes to evaluating the machine’s capabilities and your project requirements, knowing what to look for can help you make an informed decision. By effectively matching your project demands with the right CNC router machine, you can enhance your workflow, boost productivity, and achieve the quality results you desire. Whether you are a hobbyist, a small business owner, or a large-scale manufacturer, making the right choice is crucial for your success.

Understanding CNC Router Machines: Types and Applications

CNC (Computer Numerical Control) routers are versatile machining tools that have found applications across various industries, including woodworking, metalworking, and plastics manufacturing. Understanding the types of CNC routers available is crucial for selecting the best machine for your projects. Generally, CNC routers can be classified into three main categories: hobbyist, industrial, and heavy-duty machines. Hobbyist CNC routers are typically smaller, more affordable, and suited for light-duty tasks, making them ideal for DIY enthusiasts and small workshops. In contrast, industrial CNC routers are built for high precision and reliability, capable of handling extensive production demands. Heavy-duty CNC routers, often used in large-scale manufacturing settings, feature robust structures and higher spindle speeds suitable for intricate designs in harder materials.

The applications of CNC routers are vast and varied. In woodworking, they are used to create intricate designs and carvings, enabling manufacturers to produce detailed furniture components efficiently. According to a market research report by Technavio, the global CNC router market is expected to grow by approximately 15% annually, reflecting an increasing demand for automation in manufacturing processes. Furthermore, sectors such as sign-making, prototyping, and sheet metal fabrication have also seen significant advancements through the integration of CNC routing technology. As industries continue to evolve, understanding the capabilities and specifications of different CNC router types becomes essential for achieving optimal results in diverse projects.

Comparison of CNC Router Machine Types and Their Applications

Key Features to Consider When Selecting a CNC Router

When selecting a CNC router machine for your projects, it's crucial to consider several key features that can significantly impact the efficiency and quality of your work. One of the foremost aspects is the machine's rigidity and construction. A sturdy frame ensures stability during operation, reducing vibrations that can lead to inaccurate cuts. Look for machines made from high-quality materials that can withstand rigorous use while maintaining precise performance.

Another important feature to consider is the spindle power and speed. The spindle determines the cutting capability and the types of materials you can work with. Machines with higher spindle power and adjustable speed settings offer versatility, allowing you to switch between different materials and achieve optimal results. Additionally, pay attention to the bed size and travel distance. This will define the maximum size of the project you can undertake, so ensure the machine's dimensions align with your needs.

Tips: Always read reviews and gather feedback from other users about the machine you're considering. This can give you valuable insights into its performance and reliability over time. Furthermore, think about future projects and scalability; investing in a more advanced machine might save you costs in the long run as your needs grow.

How to Choose the Best CNC Router Machine for Your Projects - Key Features to Consider When Selecting a CNC Router

| Feature | Description | Importance |

|---|---|---|

| Cutting Area | The maximum size of material the router can handle. | High |

| Spindle Power | The motor's power determines cutting ability and speed. | High |

| Software Compatibility | Ability to work with design software for seamless integration. | Medium |

| Material Compatibility | Supported materials include wood, plastic, metal, etc. | High |

| Precision | The accuracy of the machine in cutting and shaping materials. | Very High |

| Ease of Use | User-friendly interfaces and setup procedures. | Medium |

| Budget | The total cost including purchase, maintenance, and operation. | High |

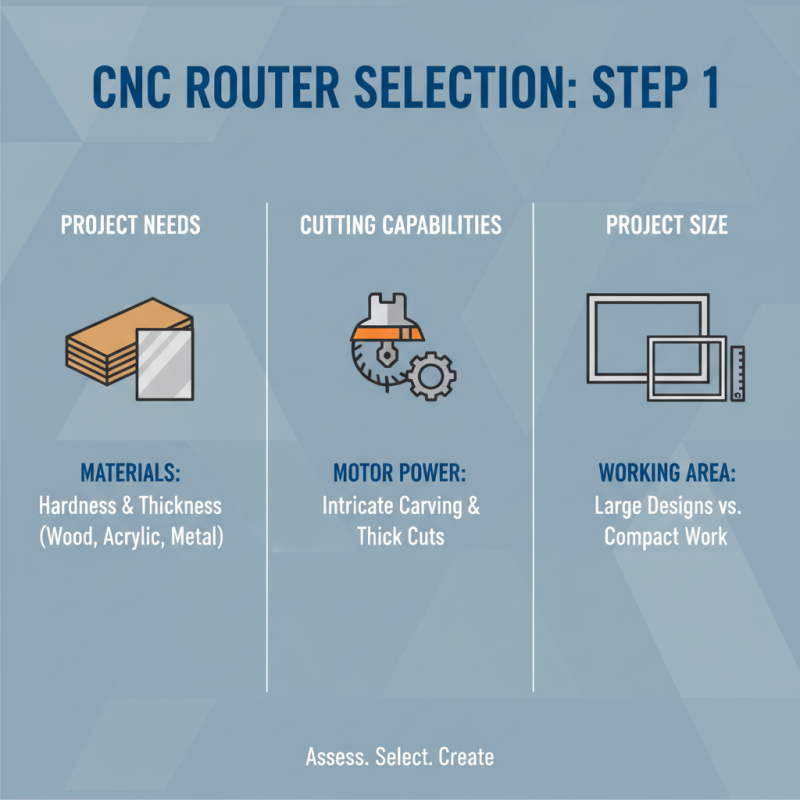

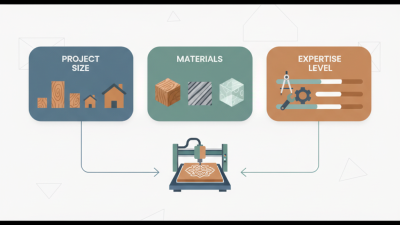

Assessing Your Project Needs and Budget for a CNC Router

When selecting a CNC router machine, the first step is to thoroughly assess your project needs. Consider the types of materials you will be working with, as different routers can handle varying levels of hardness and thickness. For example, if your projects involve intricate wood carving or cutting through thick acrylic, you need a machine equipped with the appropriate motor power and cutting capabilities. Additionally, think about the size of the projects you intend to undertake. A larger working area is essential for bigger designs, while a smaller machine may suffice for more detailed and compact work.

Budget is another crucial factor in your decision-making process. CNC routers can range significantly in price, and it's essential to balance cost with the features that meet your project demands. Determine how much you are willing to invest based on your level of usage and the complexity of tasks. Remember to factor in not just the initial purchase price, but also potential maintenance costs, software requirements, and tooling expenses. By understanding both your project specifications and financial constraints, you can make a well-informed decision that aligns with your creative ambitions while keeping your budget in check.

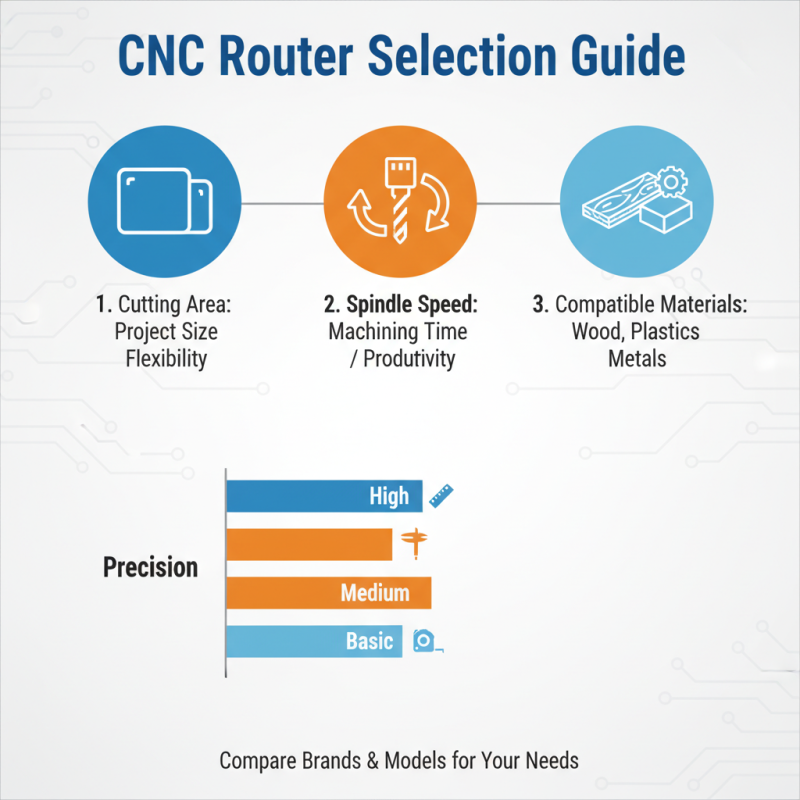

Comparing CNC Router Brands and Models: A Guide

When selecting a CNC router machine for your projects, it's essential to compare various brands and models to determine which best meets your needs. Start by evaluating the specifications, including the cutting area, spindle speed, and precision capabilities. A machine with a larger cutting area will allow for greater flexibility in project dimensions, while a higher spindle speed can enhance productivity by reducing machining time. Pay attention to the materials the machine can accommodate, as different models may be suited for wood, plastics, or metals.

Additionally, consider the ease of use, software compatibility, and available support services when comparing brands. User-friendly interfaces and robust software options will streamline your workflow, making it easier to design and modify projects. Support services, including customer support and access to tutorials, are also crucial factors, especially for beginners. By weighing these features against your project requirements, you can find a CNC router that not only fits your technical specifications but also enhances your overall user experience.

Maintenance and Support: Ensuring Longevity of Your CNC Router

Maintaining your CNC router is crucial for extending its lifespan and ensuring optimal performance. According to industry reports, regular maintenance can increase a machine's longevity by up to 50%. This includes routine tasks such as cleaning, lubricating moving parts, and checking for any signs of wear or damage. Establishing a maintenance schedule based on usage hours can help you manage these tasks effectively.

One key tip for maintenance is to keep the workspace clean and free from debris. Dust and wood shavings can accumulate in the machine, leading to overheating and mechanical issues over time. Regularly inspect the router for loose components or worn bearings, as addressing these issues early can prevent costly repairs. Moreover, investing in quality replacement parts when needed ensures your machine continues to operate efficiently.

Additionally, having access to reliable technical support can significantly enhance the longevity of your CNC router. Many manufacturers offer resources such as online tutorials, repair guides, and customer service lines. Utilizing these resources can aid in troubleshooting common issues before they escalate into serious problems. Engaging with community forums can also provide insights into best practices and innovative maintenance strategies from other users.

Related Posts

-

Top 5 CNC Router Kits for Ultimate Precision and DIY Projects in 2023

-

Top 10 CNC Router Machine Features You Should Know Before Buying

-

Exploring the Amazing World of CNC Routers for DIY Enthusiasts

-

Top 10 Small CNC Machines for Precision Engineering in 2023

-

Top 5 CNC Router Kits for Precision Crafting and DIY Projects

-

How to Choose the Best CNC Router Kit for Your Woodworking Projects