- Home

-

-

-

Stiles Enhancement Technologies

-

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

-

-

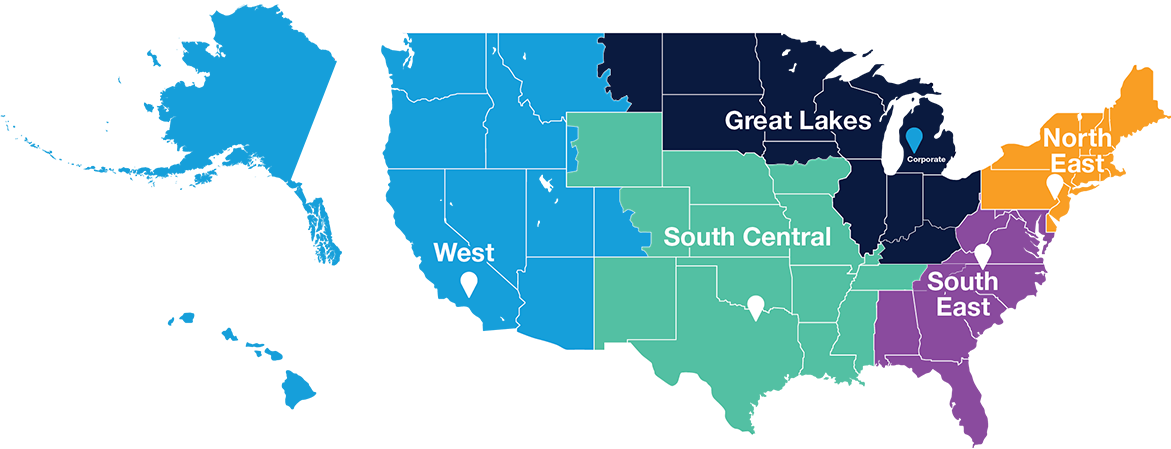

- Stiles Machinery hosts a national network of five regional service centers and nationwide force of over 200 Field Service Representatives put the industry’s best service where it belongs – close to you.

- Routine & Preventative Maintenance

- Technical Support & Diagnostics

- Field Service

- Request an Equipment Manual

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615

Service & Repairs: 616-698-7500

24/7 Parts: 1-800-727-8780

sale@inlandmachineokc.com

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

-

With a customized Stiles University course, we can provide expert training for your team, on-location. Whether it's programming, operation or maintenance, we want to help you train your personnel to meet your production goals efficiently and effectively.

-

Experience the trusted workforce development training and machinery knowledge you rely on from Stiles University, now at your convenience. With technology changing every day and new methods being developed constantly, Stiles University Online has the latest information and training content available at your fingertips.

-

Your solution for workforce development.

616-698-7500

-

-

-

Do you want to produce more efficiently? Processes and flows are key. We optimize these together with you, re-organize them and make sure that you reduce your lead time and save costs. This enables you to implement customized manufacturing and achieve your business goals.

-

Industrialized construction is evolving. Automation, robotics and advanced technology are raising the level of productivity, efficiency and precision for builders in North America.

-

Stiles Machinery is at the forefront of providing technology and machining for producing high quality mass timber. Automated solutions for your mass timber production can increase your manufacturing quality and productivity.

-

Project management services from Stiles make it easy to streamline your entire project— from concept and consultation to integration and implementation.

-

- Online Store

- News

- Careers

- REQUEST INFO

- Home

-

-

-

Stiles Enhancement Technologies

-

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

-

-

- Stiles Machinery hosts a national network of five regional service centers and nationwide force of over 200 Field Service Representatives put the industry’s best service where it belongs – close to you.

- Routine & Preventative Maintenance

- Technical Support & Diagnostics

- Field Service

- Request an Equipment Manual

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615

Service & Repairs: 616-698-7500

24/7 Parts: 1-800-727-8780

sale@inlandmachineokc.com

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

-

With a customized Stiles University course, we can provide expert training for your team, on-location. Whether it's programming, operation or maintenance, we want to help you train your personnel to meet your production goals efficiently and effectively.

-

Experience the trusted workforce development training and machinery knowledge you rely on from Stiles University, now at your convenience. With technology changing every day and new methods being developed constantly, Stiles University Online has the latest information and training content available at your fingertips.

-

Your solution for workforce development.

616-698-7500

-

-

-

Do you want to produce more efficiently? Processes and flows are key. We optimize these together with you, re-organize them and make sure that you reduce your lead time and save costs. This enables you to implement customized manufacturing and achieve your business goals.

-

Industrialized construction is evolving. Automation, robotics and advanced technology are raising the level of productivity, efficiency and precision for builders in North America.

-

Stiles Machinery is at the forefront of providing technology and machining for producing high quality mass timber. Automated solutions for your mass timber production can increase your manufacturing quality and productivity.

-

Project management services from Stiles make it easy to streamline your entire project— from concept and consultation to integration and implementation.

-

- Online Store

- News

- Careers

- REQUEST INFO

- Home

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

- TECHNICAL SUPPORT

- FIELD SERVICE

- ROUTINE & PREVENTATIVE MAINTENANCE

- REQUEST AN EQUIPMENT MANUAL

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615 Service & Repairs: 616-698-7500 24/7 Parts: 1-800-727-8780

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

- IN-PERSON TRAINING

- CUSTOMIZED COURSES & TRAINING

- STILES UNIVERSITY ONLINE

-

Your solution for workforce development.

- Online Store

- News

- Careers

- FINANCING

- Blog

- REQUEST INFO

- Home

-

-

-

- Stiles can introduce you to advances in software integration. From raw materials to design, from production to shipping, our solutions help you manage your manufacturing processes by delivering more powerful information and greater control.

- Integration

- Data Development

- Training

- Maintenance & Support

-

- TECHNICAL SUPPORT

- FIELD SERVICE

- ROUTINE & PREVENTATIVE MAINTENANCE

- REQUEST AN EQUIPMENT MANUAL

-

For support and service of your machinery, Stiles has experts available 24/7 to help reduce downtime and get you back in action.

Technical Support: 616-698-6615 Service & Repairs: 616-698-7500 24/7 Parts: 1-800-727-8780

-

-

Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center.

24/7 Parts: 800-727-8780

-

- IN-PERSON TRAINING

- CUSTOMIZED COURSES & TRAINING

- STILES UNIVERSITY ONLINE

-

Your solution for workforce development.

- Online Store

- News

- Careers

- FINANCING

- Blog

- REQUEST INFO

Top 10 Benefits of Using a Wood CNC Machine for Your Projects?

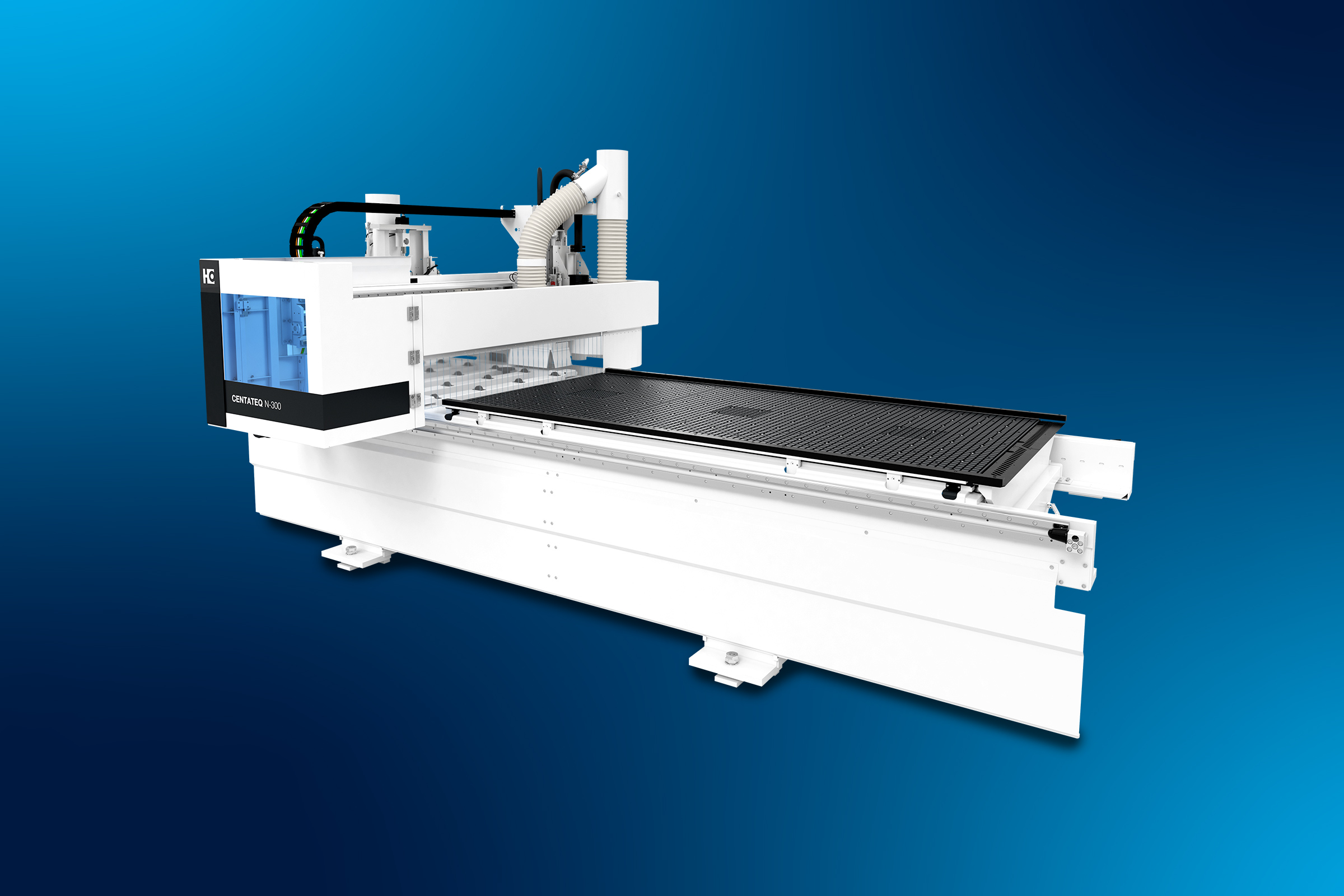

The rise of technology has transformed woodworking. A wood CNC machine stands at the forefront of this evolution. According to a recent industry report, the global CNC machine market is projected to reach $100 billion by 2025. This signifies a growing demand for precision and efficiency in woodworking.

A wood CNC machine can automate complex designs and reduce production time. This increases productivity, which is critical for businesses. An impressive 70% of companies that have adopted CNC technology reported improved efficiency. However, the initial investment can be daunting for small businesses. It’s essential to evaluate the long-term benefits against short-term costs.

Many craftsmen are exploring this technology but face a learning curve. Embracing the wood CNC machine can lead to dazzling designs. Yet, without proper training, mistakes can happen. Balancing creativity with technology is key to unlocking its full potential.

Advantages of Precision in Woodworking with CNC Machines

Precision in woodworking has fundamentally evolved with the advent of CNC machines. Data from industry reports indicate that CNC technology can achieve accuracy levels of up to 0.001 inches. This precision elevates the quality of wood projects. Complex designs that once took days to cut by hand can now be completed in hours. It reduces human error and material waste significantly.

Crafting intricate patterns or custom designs is straightforward with CNC machines. A study noted that businesses using CNC equipment saw a 30% increase in production efficiency. However, reliance on this technology may induce a lack of hands-on experience for new woodworkers. The beauty of imperfection in handmade items is sometimes lost. Workers might rely too heavily on machines and miss learning traditional skills.

Even with these cons, the benefits of precision cannot be ignored. CNC machines enable seamless integration of design and execution. Projects can be replicated easily and with consistency, which is advantageous for scaling production. Yet, the risk of becoming overly dependent on machines is present, making it vital to strike a balance. Incorporating both techniques could yield the best results in woodworking.

Increased Production Speed and Efficiency Using CNC Technology

Using a wood CNC machine can significantly enhance production speed and efficiency. CNC technology allows for automated precision in cutting and shaping wood. This means that complex designs can be achieved more quickly than with traditional methods. The machines run continuously, reducing downtime. Many projects that took hours can now be completed in minutes.

However, not everything is perfect. Machines require regular maintenance to keep running smoothly. If not calibrated properly, results may vary. Craftsmanship can sometimes feel overlooked when relying heavily on automation. Mistakes can happen, especially if the software is not updated. This might lead to wasted materials and time. Despite these challenges, the benefits of speed and efficiency in production are hard to ignore.

With a wood CNC machine, intricate patterns and designs become feasible. Small businesses can compete with larger manufacturers. They can produce high-quality products without a massive workforce. Errors are part of the process, but learning from them is essential. Embracing both the strengths and weaknesses of CNC technology will lead to better outcomes.

Flexibility and Versatility of Wood CNC Machines for Various Projects

Wood CNC machines offer exceptional flexibility for various projects. These machines can create intricate designs, from furniture to decor. According to a report by the National Association of Manufacturers, 80% of woodworkers use CNC technology for its precision. The ability to replicate complex patterns is unmatched. For example, a single design can be produced repeatedly without compromise in quality.

Project versatility is another key advantage. Wood CNC machines can handle numerous materials, including plywood, hardwood, and MDF. This capability enables users to switch between different projects quickly. However, there can be a learning curve. Operators might struggle with software or machine settings initially. Adjusting parameters for various materials can be challenging, and meticulous calibration is essential for optimal results.

Many projects enable unique customizations, appealing to both hobbyists and professionals. Some artisans have reported spending hours fine-tuning their designs. While CNC machines can save time, the initial setup may feel daunting. Errors can occur, leading to scrap material and wasted resources. Balancing creativity with technical limitations remains a key hurdle for many users in this industry.

Enhanced Design Capabilities for Customization and Creativity

Wood CNC machines have transformed the way we approach design and creativity. With precision and accuracy, these machines allow for intricate patterns and detailed work. Imagine carving a complex design on furniture or creating custom wall art. The possibilities seem endless. Each cut can reflect personal style, turning an ordinary piece into something unique.

However, mastering wood CNC machines requires practice. It can be frustrating as you learn the nuances of planning and executing designs. Mistakes happen, and sometimes the results are not what you envisioned. These experiences provide valuable lessons. Each error pushes you to rethink your design approach and improve your skills. Embracing imperfection often leads to unexpected creativity.

Through wood CNC machining, you can explore new ideas without limitation. This technology empowers makers to experiment. Whether working on small projects or larger installations, enhancing creative expression is key. The journey may be filled with challenges, but it ultimately enriches your design capabilities and fuels your imagination.

Cost-Effectiveness in Long-Term Projects Compared to Traditional Methods

Wood CNC machines have transformed how we approach woodworking projects. They offer a level of precision that traditional methods cannot match. This precision can lead to reduced waste. When mistakes happen, which they often do, the cost of materials can add up quickly. By using a CNC machine, you can minimize these errors from the start.

In the long run, the initial investment in a CNC machine pays off. Traditional methods demand more labor and time, increasing overall costs. However, once a CNC machine is set up, it can produce complex designs efficiently. Imagine working on intricate patterns that are nearly impossible by hand. While the learning curve can be steep, the time saved is invaluable.

It’s worth noting that programming a CNC machine often requires technical knowledge. This can be a barrier for those used to conventional methods. Getting accustomed to the technology might take longer than expected. Still, embracing this modern approach can lead to significant savings over time. Projects that used to take weeks can now be completed in days or even hours.

Related Posts

-

Unlocking the Potential of Wood CNC Machines for Your Next Creative Project

-

2026 Top Woodworking CNC Machines: Features, Benefits, and Buying Guide

-

How to Choose the Best CNC Router Machine for Your Projects

-

The Ultimate Guide to Choosing the Perfect Sanding Machine for Your DIY Projects

-

Unlocking Creativity: How CNC Wood Cutting Machines Transform Custom Furniture Design

-

How to Choose the Best Wide Belt Sander for Your Woodworking Projects