Emerging Innovations in Transmission Line Stringing Tools and Their Impact by 2025

The landscape of electrical infrastructure is evolving rapidly, driven by advancements in technology and rising demands for efficient power distribution. Among these developments, the emergence of innovative Transmission Line Stringing Tools stands out as a pivotal factor in enhancing the construction and maintenance of transmission lines. By 2025, these tools are expected to revolutionize traditional methods, significantly improving efficiency, safety, and performance. This blog will explore the latest innovations in transmission line stringing tools, examining their design, functionality, and the profound impact they are likely to have on the energy sector. As we delve into these advancements, we will highlight the critical role they play in meeting growing energy demands while maintaining stringent safety and environmental standards. Join us as we uncover the future of transmission line stringing and its implications for the renewable energy landscape.

Emerging Trends in Transmission Line Stringing Technology: A 2025 Perspective

As we look ahead to 2025, the transmission line stringing technology is witnessing remarkable advancements that promise to enhance efficiency and safety in power transmission. The global market for stringing tools is projected to grow significantly, with reports indicating an increase in demand for high-performance equipment driven by the need for infrastructure upgrades and renewable energy integration. According to a recent industry report, the market for stringing tools is expected to reach $1.2 billion by 2025, reflecting a compound annual growth rate (CAGR) of 5.4%. This surge is largely attributed to the adoption of innovative materials and designs that reduce weight and improve load handling capabilities.

One notable trend is the integration of automation and robotics in stringing practices. These technologies not only streamline operations but also enhance safety by minimizing manual handling risks. Companies are increasingly investing in automated systems that can manage the stringing process remotely, allowing operators to monitor in real time and making adjustments as needed. Additionally, the incorporation of smart sensors into stringing tools is providing invaluable data that improves operational efficiency and predictive maintenance.

Tip: For companies in the transmission sector, investing in training programs focusing on new technologies and safety protocols is crucial. This not only ensures compliance with evolving industry standards but also empowers personnel to adapt to innovations seamlessly. Keeping your workforce informed and skilled will be key to leveraging the full potential of emerging stringing technologies.

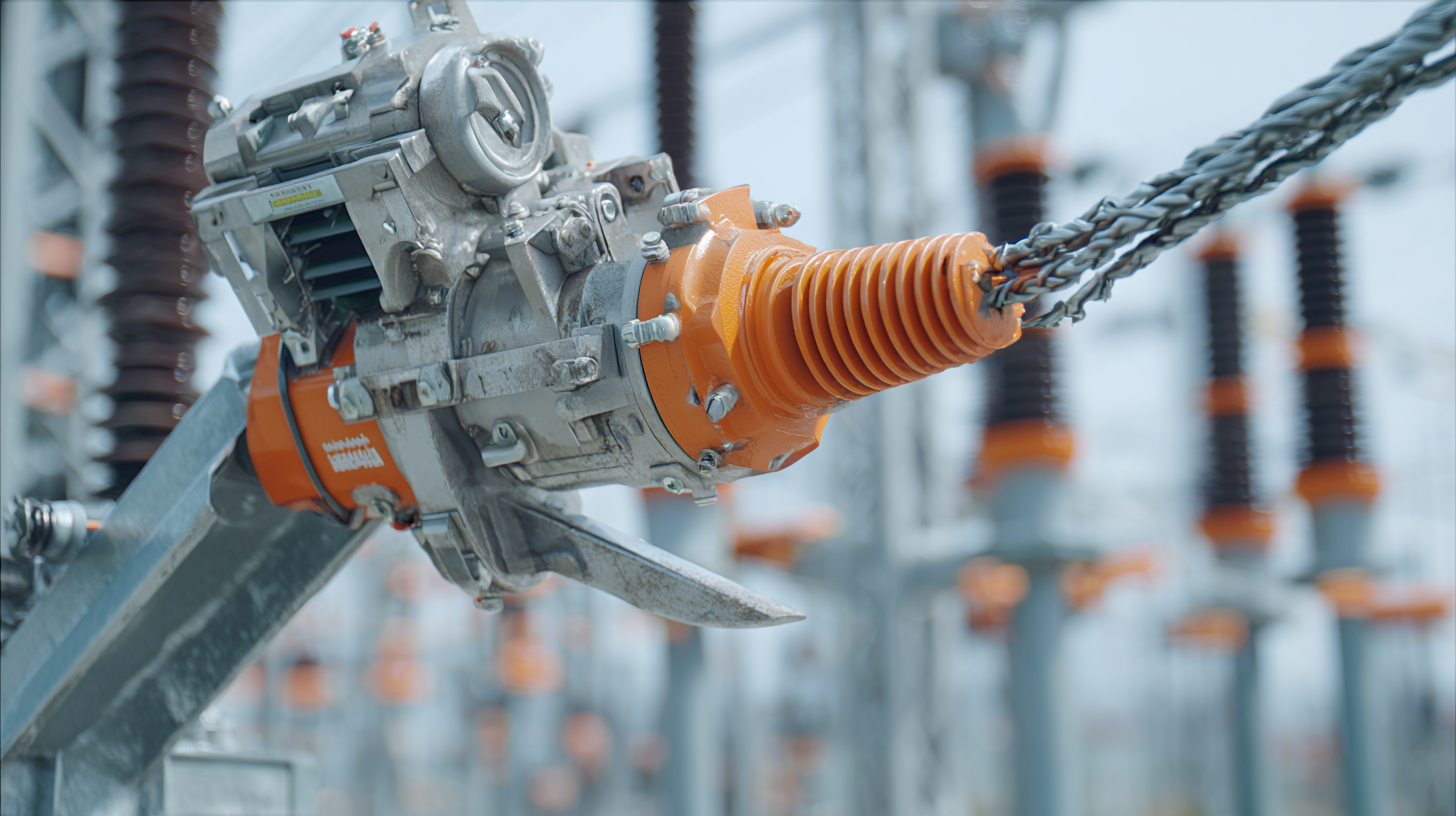

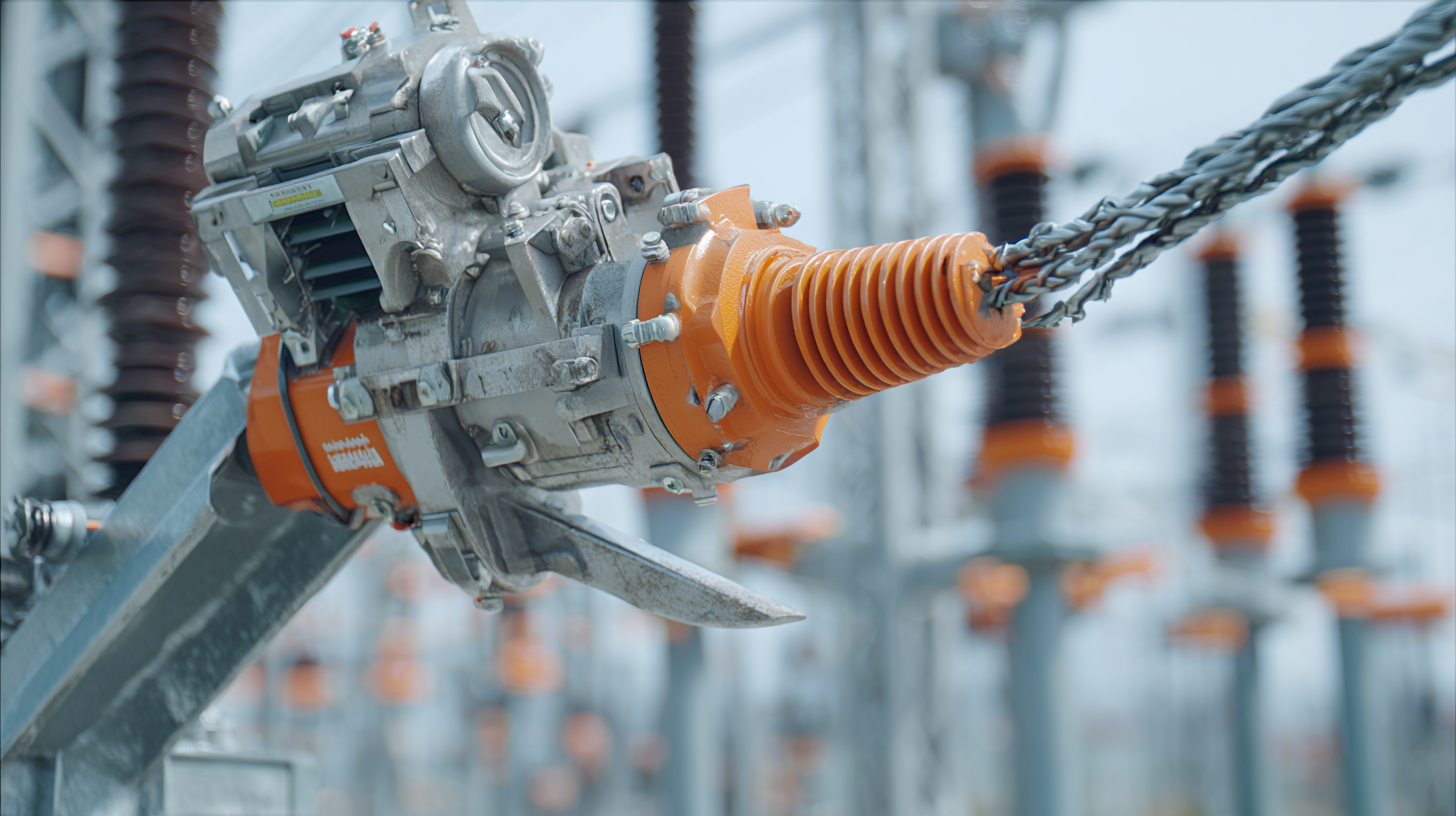

China's Role in Advancing Transmission Line Stringing Tools

China has emerged as a significant player in the development of transmission line stringing tools, with innovations reshaping the landscape of electrical infrastructure. According to a report by ResearchAndMarkets, the global market for transmission line equipment is expected to reach $12 billion by 2025, with China accounting for a substantial portion of this growth. The country’s increased investments in renewable energy have driven demand for more efficient and innovative stringing tools, aimed at enhancing the installation processes for high-voltage transmission lines.

Chinese manufacturers are leading the way in producing advanced stringing equipment. Notable advancements include automated stringing machines and drones equipped with precise measurement tools that significantly reduce installation time and labor costs. A study by Frost & Sullivan highlights that these innovations can improve operational efficiencies by up to 30%, allowing companies to complete projects faster while minimizing disruptions. As China continues to focus on modernizing its electrical grid and expanding its renewable energy capacity, its role in advancing transmission line stringing technology will be crucial for realizing ambitious energy transition goals by 2025.

Innovative Materials and Designs in Stringing Tools for Enhanced Efficiency

The transmission line industry is witnessing a wave of innovative materials and designs in stringing tools, dramatically enhancing efficiency in the installation and maintenance processes. One of the key advancements is the introduction of lightweight composites that reduce the overall load during stringing operations. By using materials such as high-strength carbon fiber, engineers can achieve a balance between durability and weight, leading to easier handling and quicker installation times. These composites not only minimize physical strain on crews but also enhance safety by allowing for more effective load management.

In addition to material advancements, ergonomic designs are transforming how stringing tools are utilized in the field. Tools now come with adjustable grips, reduced vibration features, and intuitive controls that cater to diverse operational conditions. These design improvements significantly minimize operator fatigue and increase overall productivity, facilitating faster response times during installations. As these innovative tools continue to evolve, they promise to redefine industry standards by 2025, paving the way for streamlined operations and decreased downtime in transmission line projects.

Emerging Innovations in Transmission Line Stringing Tools and Their Impact by 2025 - Innovative Materials and Designs in Stringing Tools for Enhanced Efficiency

| Innovation Type |

Material Used |

Key Features |

Potential Efficiency Gain (%) |

Expected Adoption Year |

| Advanced Pulley Systems |

Carbon Fiber |

Lightweight, High Strength |

30% |

2024 |

| Smart Stringing Tools |

Smart Alloys |

Real-time Monitoring, Remote Control |

25% |

2025 |

| Automated Winching Systems |

Aluminium Alloys |

Increased Speed, Reduced Manual Effort |

20% |

2023 |

| Innovative Rigging Systems |

Synthetic Polymers |

Flexibility, Enhanced Load Distribution |

15% |

2025 |

The Impact of Automation on Transmission Line Construction by 2025

The landscape of transmission line construction is evolving rapidly, with automation playing a pivotal role in enhancing efficiency and safety. By 2025, we can expect a marked shift towards automated processes in the construction of transmission lines, driven by advancements in technology. At events like bauma 2025, the unveiling of new construction equipment showcases breakthroughs in hydraulics and automated systems. These innovations promise to streamline operations, allowing for more precise and less labor-intensive installation of transmission lines.

Moreover, the recent rulings and legislative changes across various regions underscore the growing emphasis on efficient energy distribution. For instance, the Chhattisgarh High Court's decision to allow the installation of electricity transmission lines without prior landowner consent could expedite project timelines significantly. As new laws, such as those passed in Illinois, impose requirements for prevailing wages and tax incentives for high voltage projects, the industry is directed towards a future where automation and technological integration become fundamental. This combination of regulatory support and innovative tools will not only transform the construction process but also help meet the evolving energy demands by 2025.

Emerging Innovations in Transmission Line Stringing Tools and Their Impact by 2025

As transmission line construction evolves towards automation by 2025, this chart illustrates the perceived impact level of various innovative tools, highlighting the importance of automation and robotics in enhancing efficiency and safety during the stringing process.

Quality Control and Standards in China's Transmission Line Equipment Manufacturing

The landscape of China's transmission line equipment manufacturing is rapidly evolving, driven by the implementation of quality control measures and stringent industry standards. According to a recent market report, the demand for high-quality transmission line tools is projected to grow at a CAGR of 7.2% from 2023 to 2025, emphasizing the industry's shift towards more reliable and efficient equipment. Innovations in stringing tools, which include advanced materials and automation technology, play a crucial role in meeting these new standards, ensuring that the equipment not only meets regulatory requirements but also enhances overall operational efficiency.

Tip: When considering transmission line equipment, focus on manufacturers who adhere to

ISO 9001 standards, as this certification signifies a strong commitment to quality management practices. Furthermore, investing in state-of-the-art stringing tools can significantly reduce project timelines, ensuring a smoother installation process.

Quality control protocols have become indispensable in China, with many manufacturers adopting cutting-edge technologies like IoT integration for real-time monitoring and performance assessment. This advancement helps to identify potential issues before they escalate, resulting in a more robust supply chain. By 2025, it’s predicted that over 60% of manufacturers will implement digital quality assurance systems, highlighting the industry's commitment to maintaining high standards and enhancing product reliability.

Tip: Always request documentation regarding the quality control processes from manufacturers, as transparency in these practices can provide better insight into the product's reliability and longevity.